Flatcar chassis overturning device

A technology of turning over device and chassis, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing difficulty in adjustment and repair, distortion of chassis composition, hidden safety hazards, etc., and achieve convenient installation and positioning operation. , Guarantee the welding quality and avoid the effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

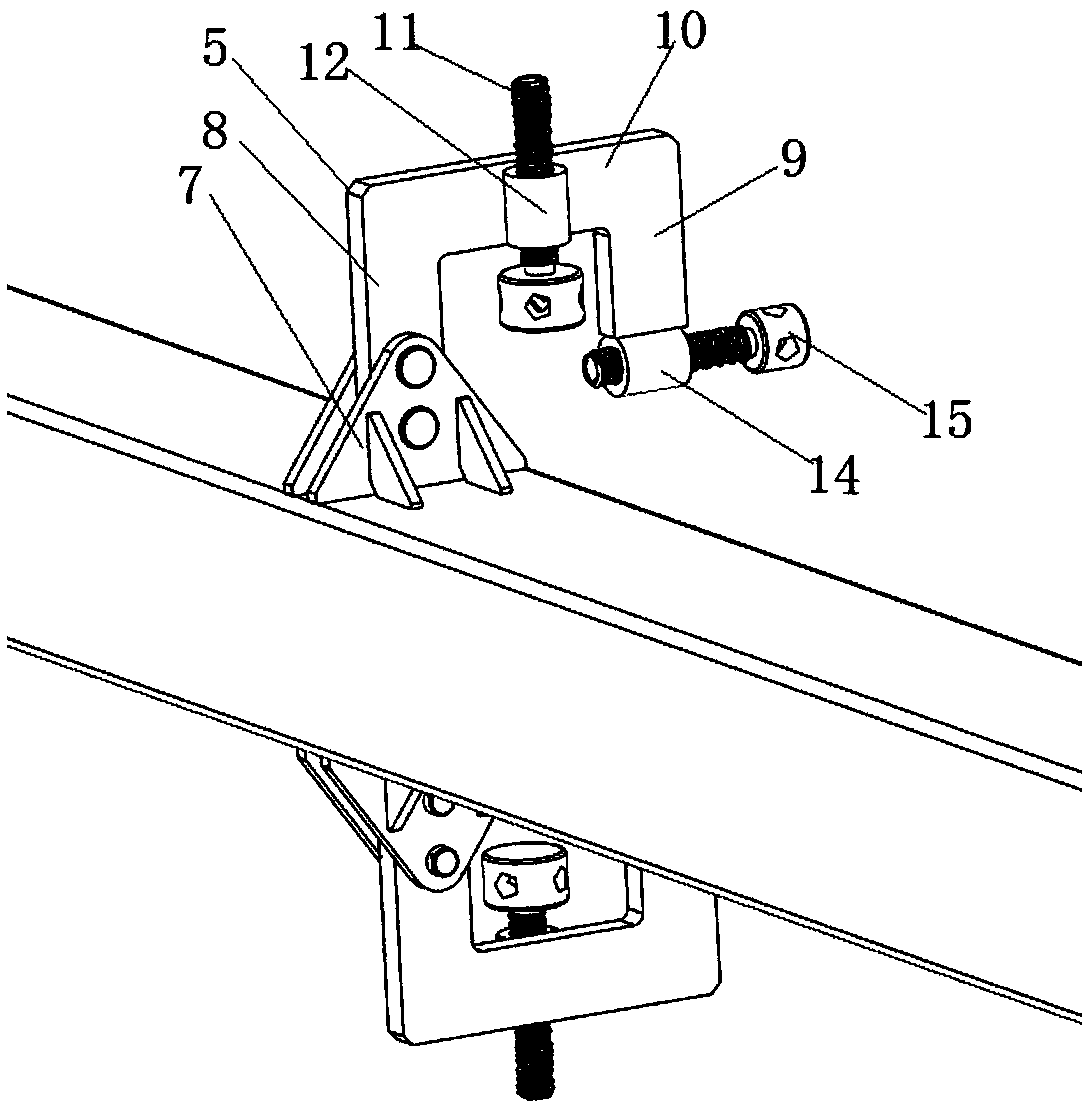

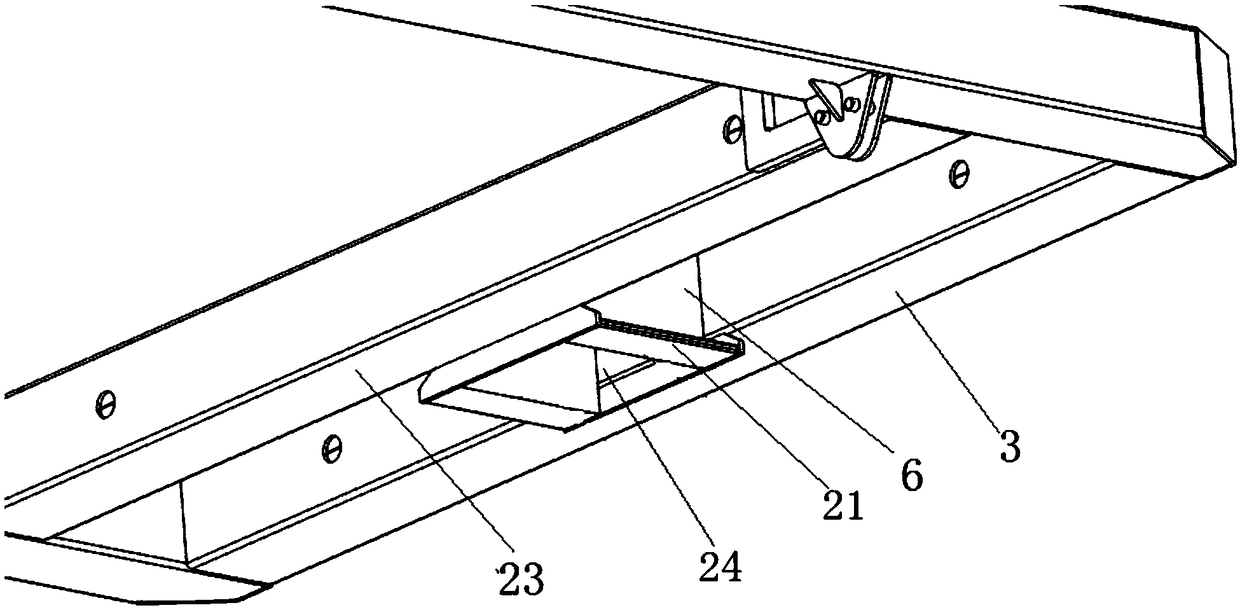

[0054] figure 1 It shows a schematic structural view of the underframe turning device of a flat car in one embodiment of the present invention, figure 2 shows a schematic structural view of the support positioning mechanism in one embodiment of the present invention, image 3 A schematic structural view of the flipped tire connector in one embodiment of the present invention is shown, Figure 4 A schematic structural view of the flip tire fixing frame in one embodiment of the present invention is shown, Figure 5 A schematic diagram of the installation of the flipped tire fixing frame and the flipped tire connecting frame in one embodiment of the present invention is shown, Figure 6 A schematic diagram of the installation of the partial frame of the underframe of the flat car and the support positioning mechanism in one embodiment of the present invention is shown.

[0055] Such as Figures 1 to 6 Shown, a kind of flat car underframe turnover device of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com