Air vent equipped hood side plate

A vent and hood technology, applied in the field of hood side panels with vents, can solve the problem of inability to effectively remove fine impurities in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation will be described below in conjunction with the accompanying drawings.

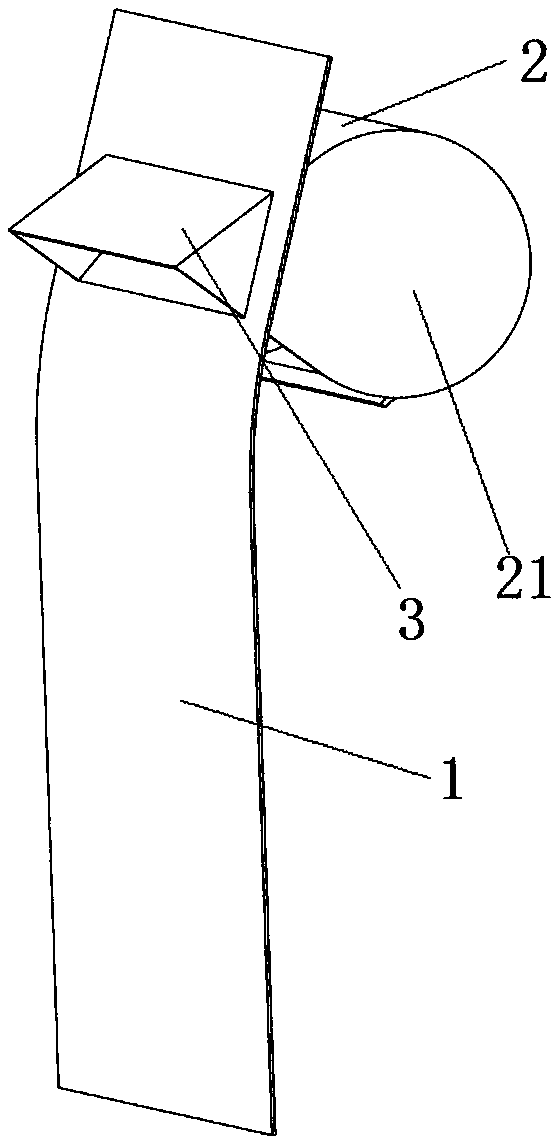

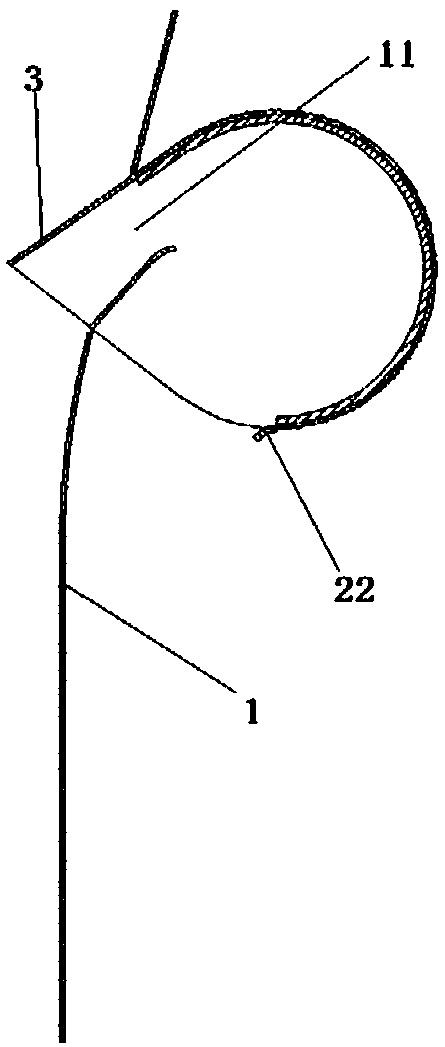

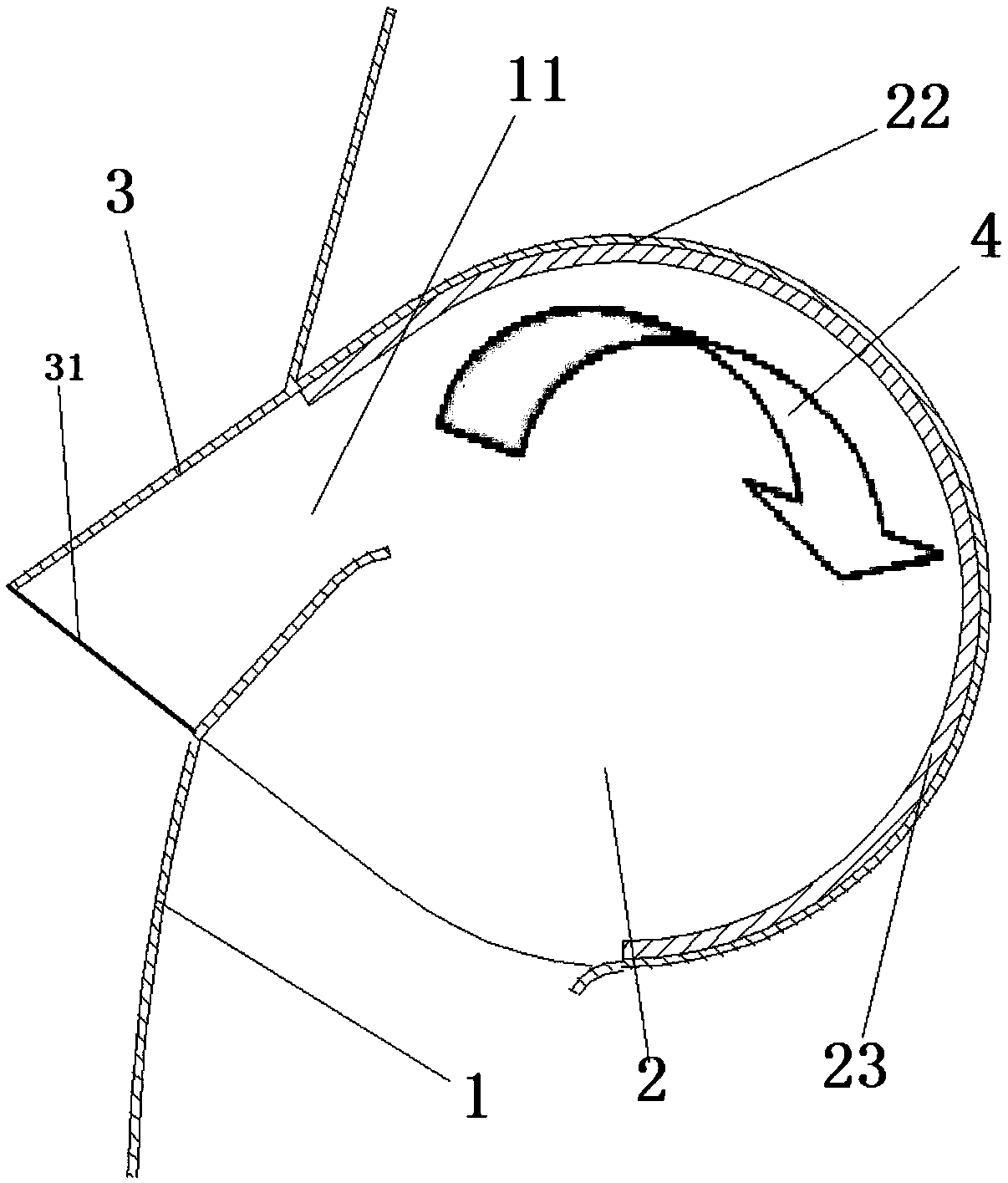

[0018] The hood side panel in this embodiment is as Figure 1 to Figure 3 As shown, the hood side panel 1 can be used for the wall panel of the hood, and can also be used for the upper door panel of the hood. Ventilation opening 11 is arranged on this hood side plate, and ventilation opening 11 is square. An air outlet channel 2 is arranged on the inner side of the hood side plate 1 , and an air inlet channel 3 is fixedly arranged on the outer side of the hood side plate. The air outlet guide channel 2 is a cavity with an opening formed by an arc plate 22 and baffle plates 21 located at both ends of the arc plate 22 , and a brush plate 23 is arranged on the inner side of the arc plate 22 . The material of the brush plate 23 tends to generate static electricity when it rubs against air.

[0019] The baffle plate 21 is detachably connected to the arc-shaped plate 22 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com