Spliced table

A table and table body technology, applied in the field of exhibition office desks, can solve the problems of exhibits landing, low splicing firmness, lack of connection structure, etc., and achieve the effect of length expansion and high splicing firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

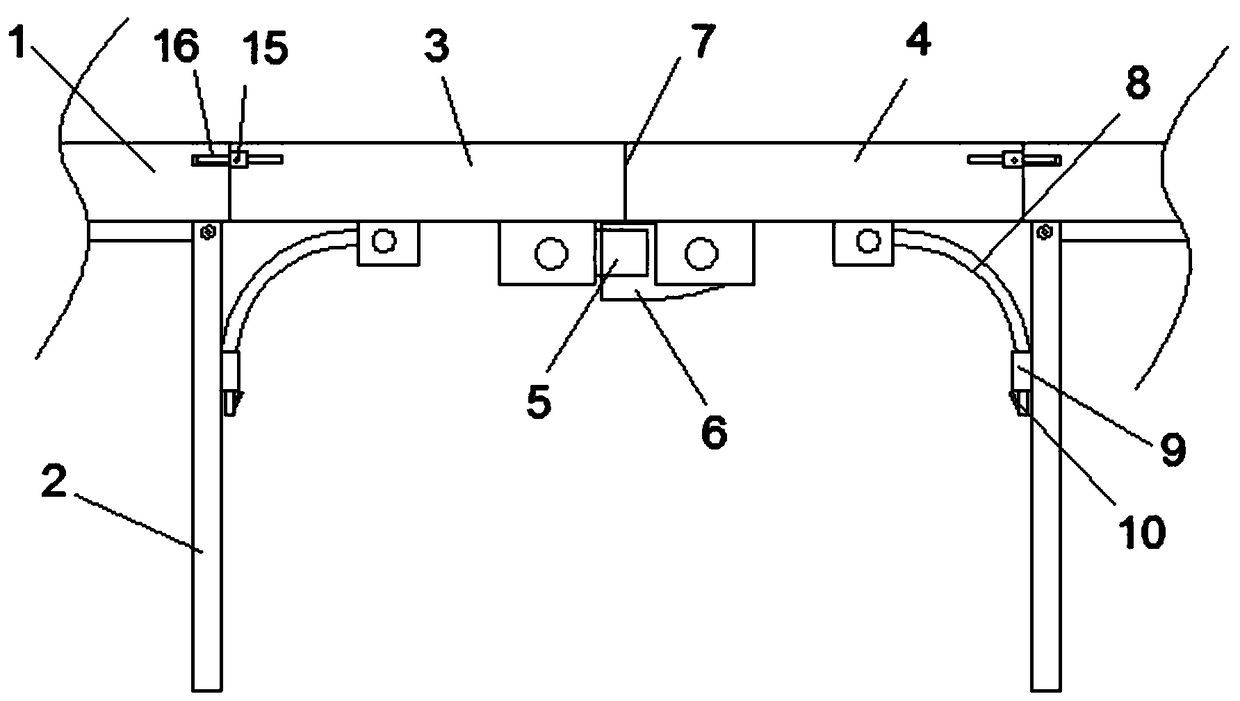

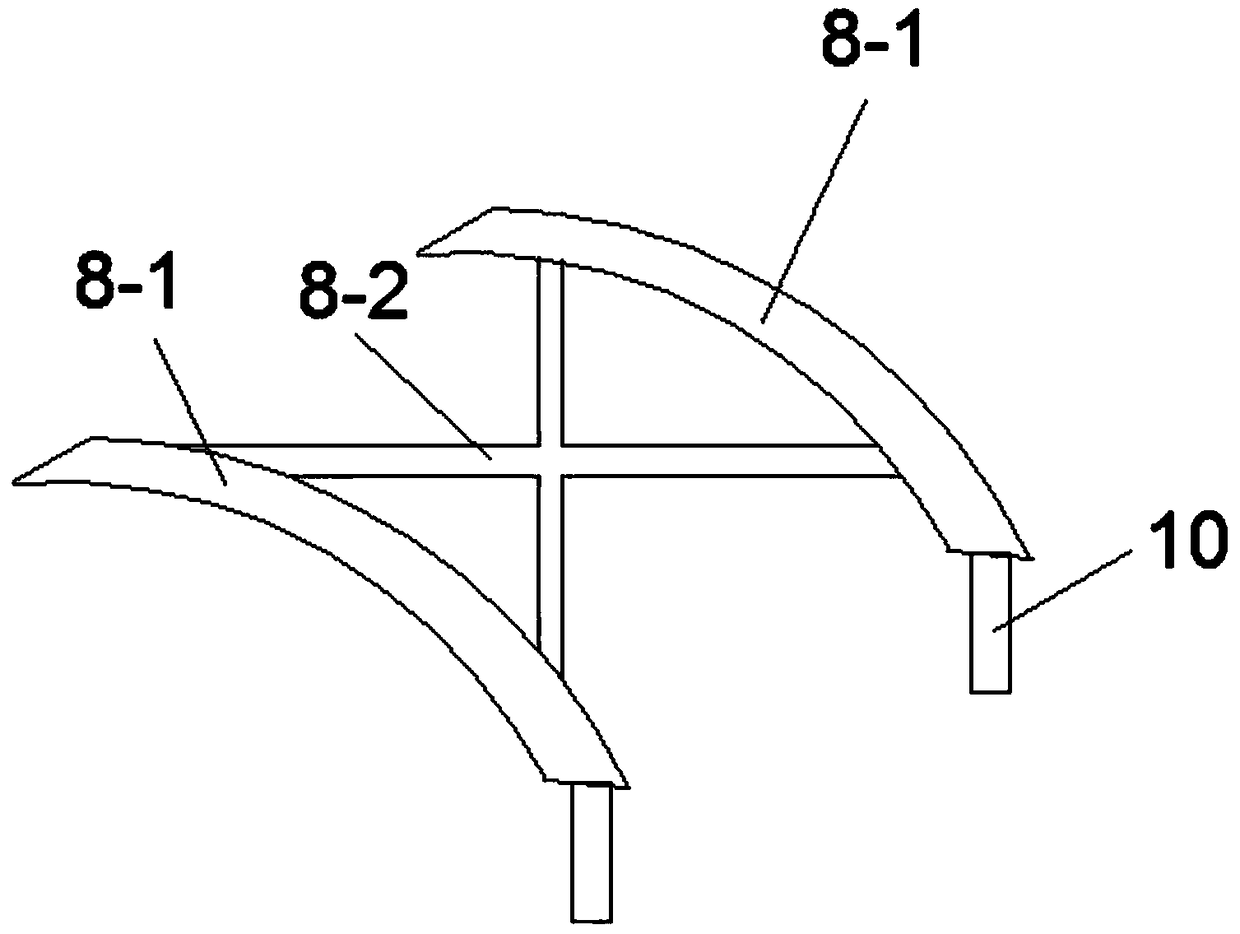

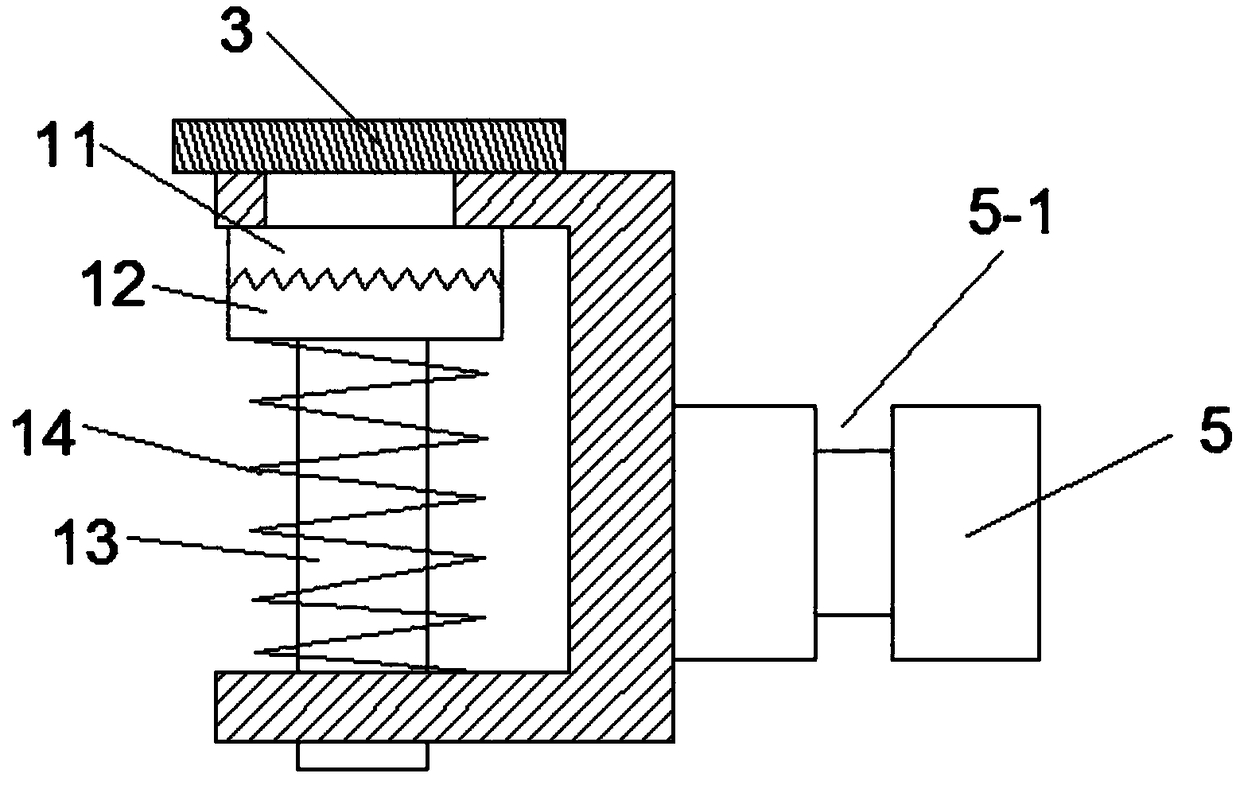

[0021] Such as figure 1 , figure 2 As shown, the embodiment of the present invention includes a table body 1, a table leg 2 is arranged under the table body 1, and a left connecting plate 3 and a right connecting plate 4 for docking are respectively arranged on both ends of the table body 1, and the left connecting plate 4 is connected to the left side. The plate 3 is only connected with the right connecting plate 4, thus forming a cascade of multiple tables. The lower surface of the end of the left connecting plate 3 is rotatably provided with a chuck 5, and the end lower surface of the right connecting plate 4 is rotatably provided with a card. Groove 6, clamp head 5 and clamping groove 6 only have the rotation range that the maximum downward rotation angle is 90°, both when clamping head 5 and clamping groove 6 are in the connected state, the axial cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com