Electronic cigarette liquid filling equipment and use method thereof

A technology of e-cigarette liquid and filling equipment, which is applied in the direction of smoker's supplies, tobacco, applications, etc., can solve the problems of troublesome use of filling devices, limited application range, lack of flexibility, etc., to prevent cross-contamination, wide application range, Maintain Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

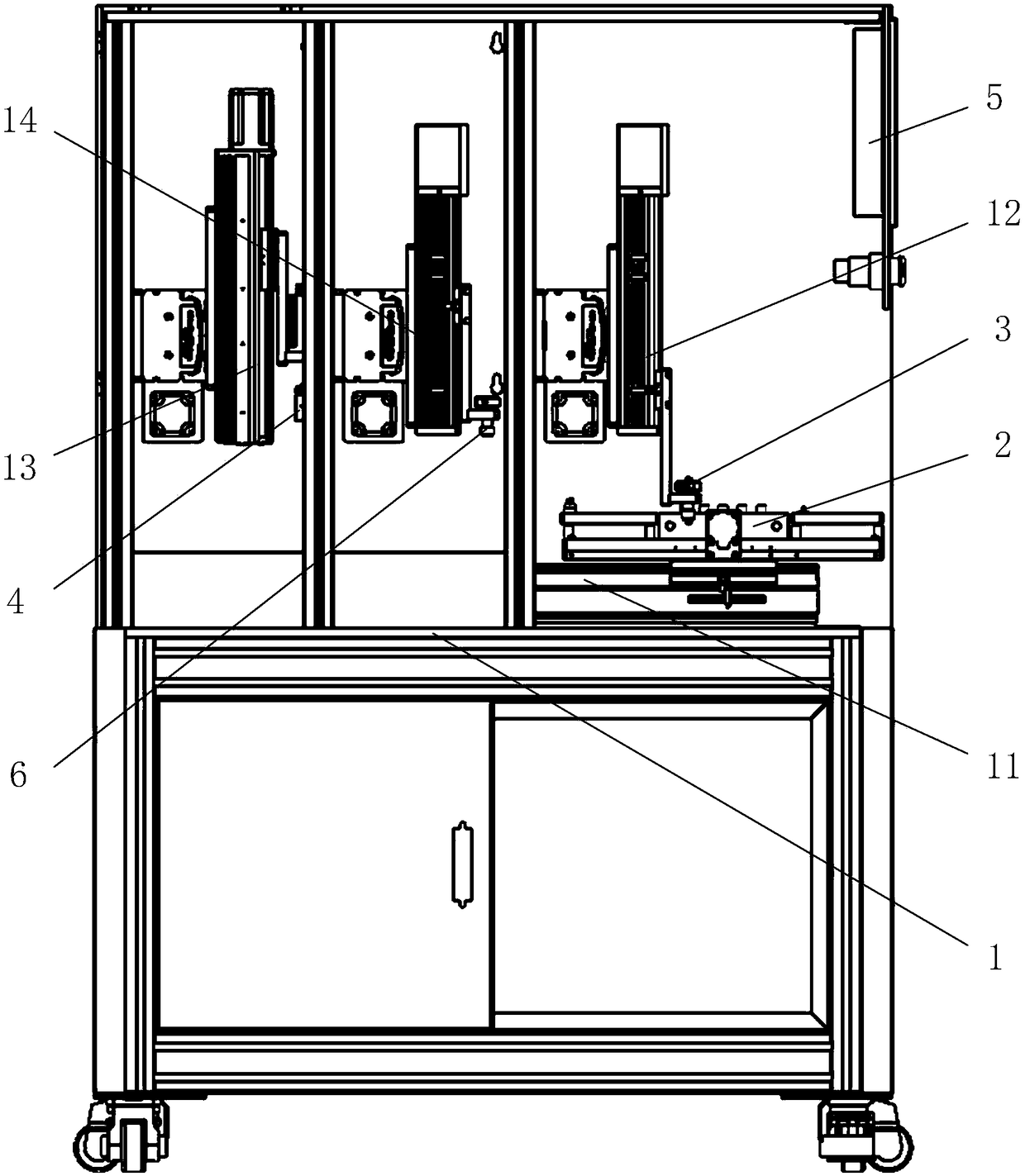

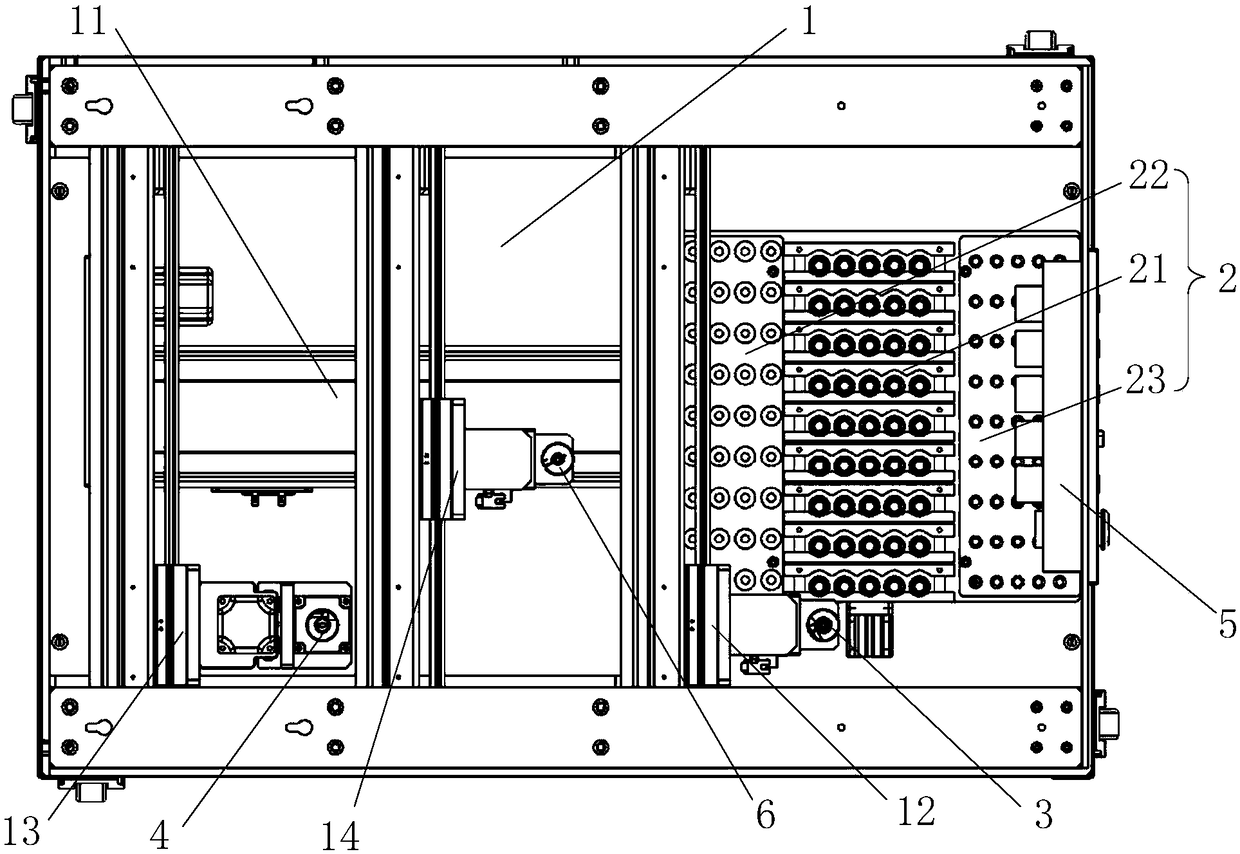

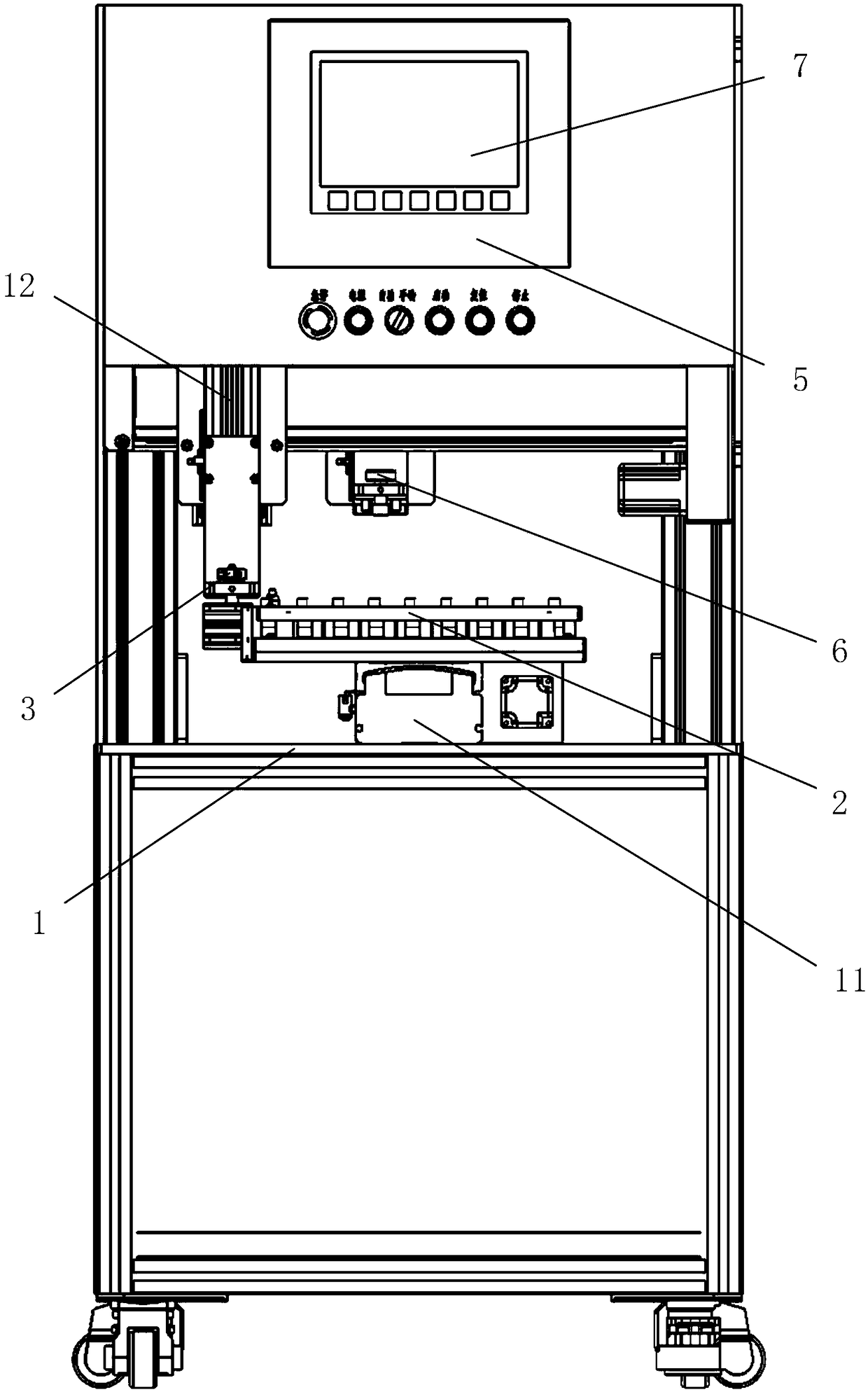

[0042] Such as Figure 1~4 As shown in . 2. Filling unit 3 , capping unit 4 , storage unit (not shown in the figure) and control unit 5 .

[0043] Wherein, the main body 1 is a three-axis horizontal Cartesian coordinate platform, which can accurately determine the coordinates of each spatial position on the main body 1 .

[0044] The e-liquid bottle storage unit 2 is installed on the platform of the main body 1 and can move horizontally relative to the main body 1 to move to the working position of the filling unit 3 or the working position of the capping unit 4. The e-liquid bottle storage unit 2 can be accurately determined with reference to the main body 1. The coordinates of the liquid bottle storage unit 2; the e-liquid bottle storage unit 2 includes a bottle accommoda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com