A proton exchange membrane fuel cell stack blow-by gas flow detection device and method

A technology of fuel cell stacks and proton exchange membranes, applied in fuel cells, fuel cell control, fuel cell additives, etc., can solve problems such as damage to measurement containers, damage to test personnel, and large human influence, achieving high accuracy, Labor saving and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

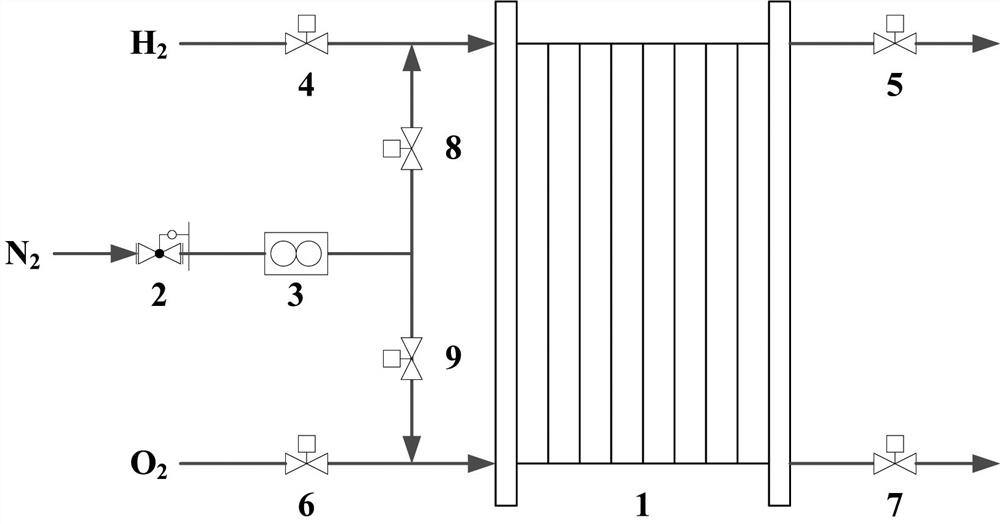

[0022] Such as figure 1 Shown is a basic embodiment of the invention.

[0023] A proton exchange membrane fuel cell stack blow-by gas flow detection device, comprising a fuel intake pipeline for connecting a fuel chamber and a proton exchange membrane fuel cell stack 1, and a fuel intake pipeline for connecting an oxidant chamber and a proton exchange membrane fuel cell stack 1 The oxidant inlet pipeline, and the fuel inlet solenoid valve 4 arranged on the fuel inlet pipeline and the oxidant inlet solenoid valve 6 arranged on the oxidant inlet pipeline also include fuel for connecting the proton exchange membrane fuel cell stack 1 The gas outlet pipeline and the oxidant gas outlet pipeline, as well as the fuel outlet solenoid valve 5 and the oxidant outlet solenoid valve 7 respectively arranged on the fuel outlet pipeline and the oxidizer outlet pipeline, also include the main test gas pipeline and the electric motors arranged on the main test gas pipeline in turn. Pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com