Detection method of an automobile dashboard tool box

A technology of automobile instrumentation and detection method, applied in the automobile field, can solve the problems of sticking, low accuracy level, and large temperature influence of plastic parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail below in conjunction with the drawings.

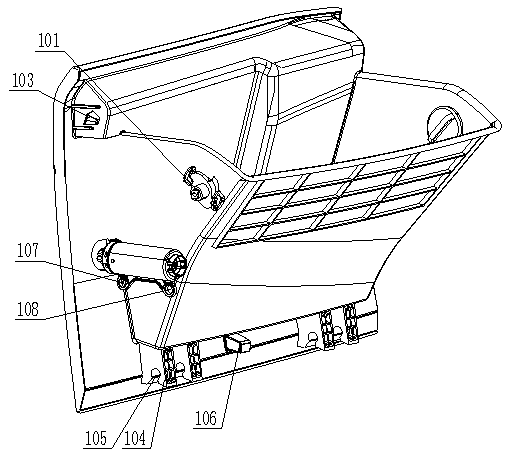

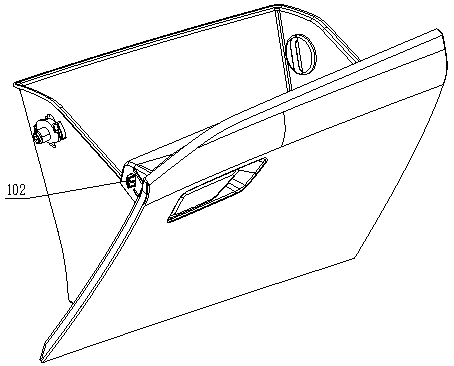

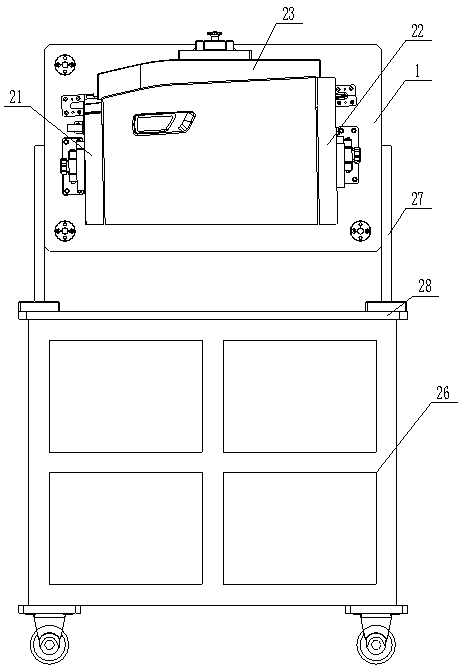

[0073] When implementing: Figure 1 to Figure 10 As shown, a detection method for a toolbox of an automobile instrument panel includes the following steps: a. The main body of the inspection toolbox is set on a seat plate that can be turned vertically; b. After the main body of the inspection tool is rotated to the vertical state, position the tool box to be tested on the main body of the inspection tool according to the corresponding orientation. After positioning the tool box to be tested on the main body of the inspection tool, complete the "U" on the tool box to be tested. ”-Shaped slot and limit post; c complete the accuracy detection of the left lock tongue, right lock tongue and damping rod connecting hole on the toolbox to be tested; d then rotate the main body of the inspection tool to a horizontal state by rotating the seat plate After that, the contour accuracy o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com