Composite passivator for heavy metals in soil and using method of composite passivator

A technology of heavy metal and passivating agent, applied in the field of soil treatment, can solve the problems of large amount of addition, expensive organic repair agent, decomposition and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

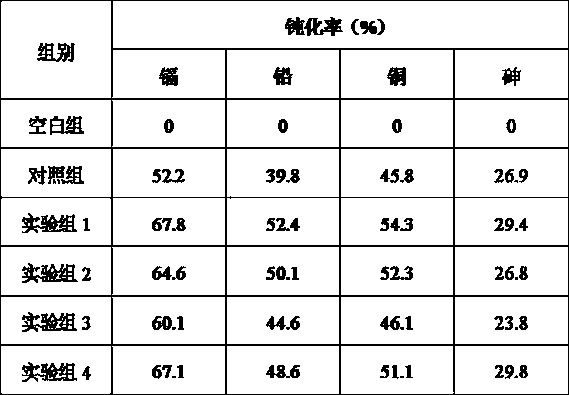

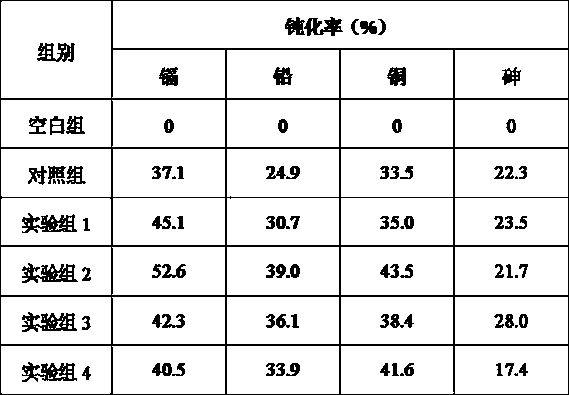

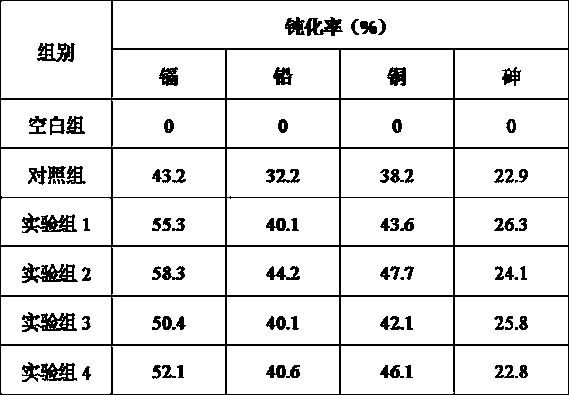

Embodiment 1

[0014] A soil heavy metal compound passivation agent is composed of the following components in mass ratio: 50% of phosphate rock, 15% of calcium hydrogen phosphate, 25% of calcium magnesium phosphate fertilizer, and 10% of sintering red mud.

[0015] The phosphate rock and sintering red mud are dried and passed through a 100-mesh sieve, and then mixed with calcium hydrogen phosphate and calcium magnesium phosphate fertilizer to obtain the finished product.

Embodiment 2

[0017] A soil heavy metal compound passivator is composed of the following components in mass ratio: 40% of phosphate rock, 20% of calcium hydrogen phosphate, 20% of calcium magnesium phosphate fertilizer, and 20% of sintering red mud.

[0018] The phosphate rock and sintering red mud are dried and passed through a 100-mesh sieve, and then mixed with calcium hydrogen phosphate and calcium magnesium phosphate fertilizer to obtain the finished product.

Embodiment 3

[0020] A soil heavy metal compound passivator is composed of the following components in mass ratio: 30% of phosphate rock, 25% of calcium hydrogen phosphate, 25% of calcium magnesium phosphate fertilizer, and 20% of sintering red mud.

[0021] The phosphate rock and sintering red mud are dried and passed through a 100-mesh sieve, and then mixed with calcium hydrogen phosphate and calcium magnesium phosphate fertilizer to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com