Indoor model test method for side slopes or landslides

A test method and indoor model technology, which is applied in the field of model test research of slopes and anti-slide piles, can solve the problems of high production cost, inconvenient operation, and single function of reaction force devices, so as to speed up the test progress, improve reliability, The effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

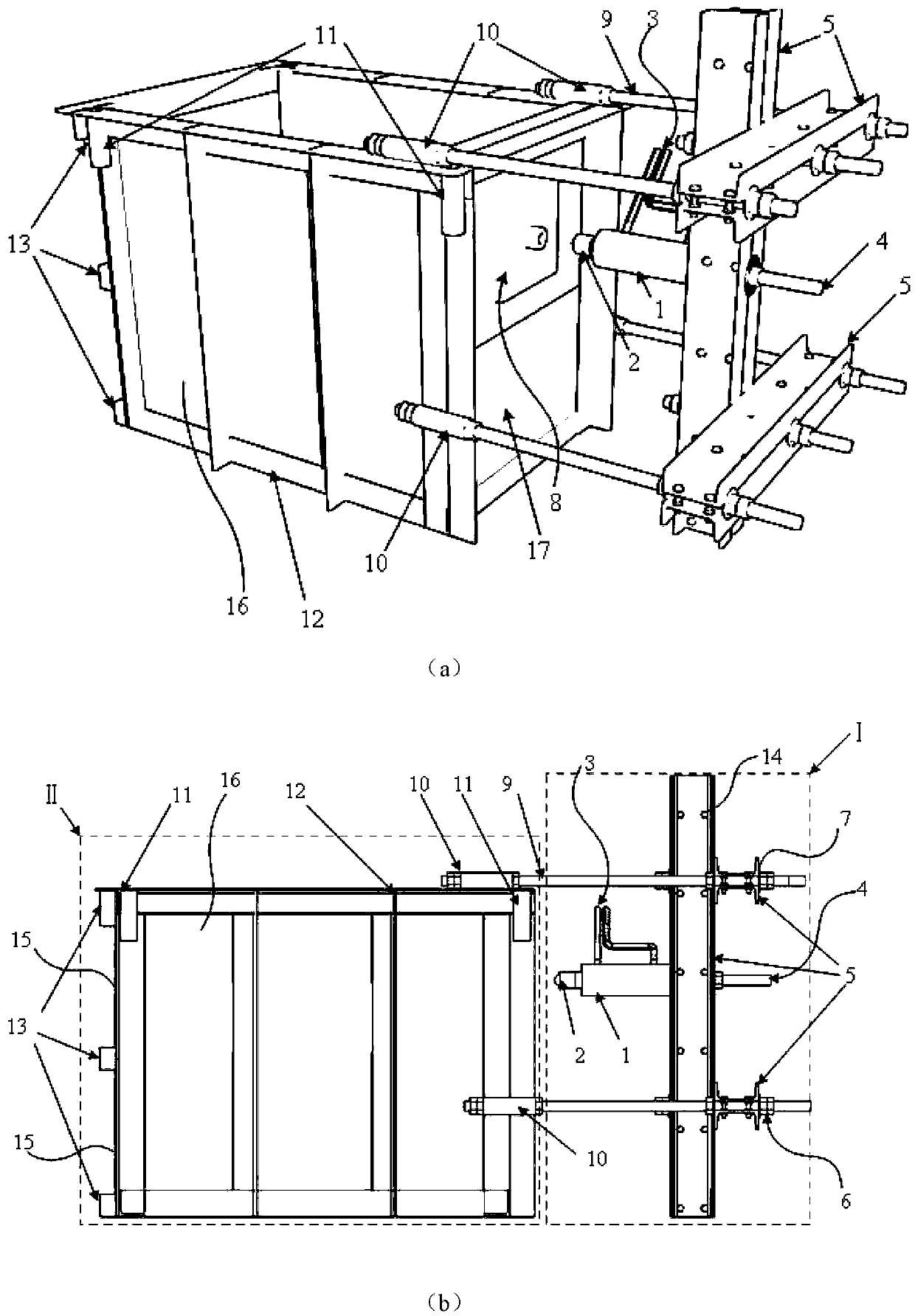

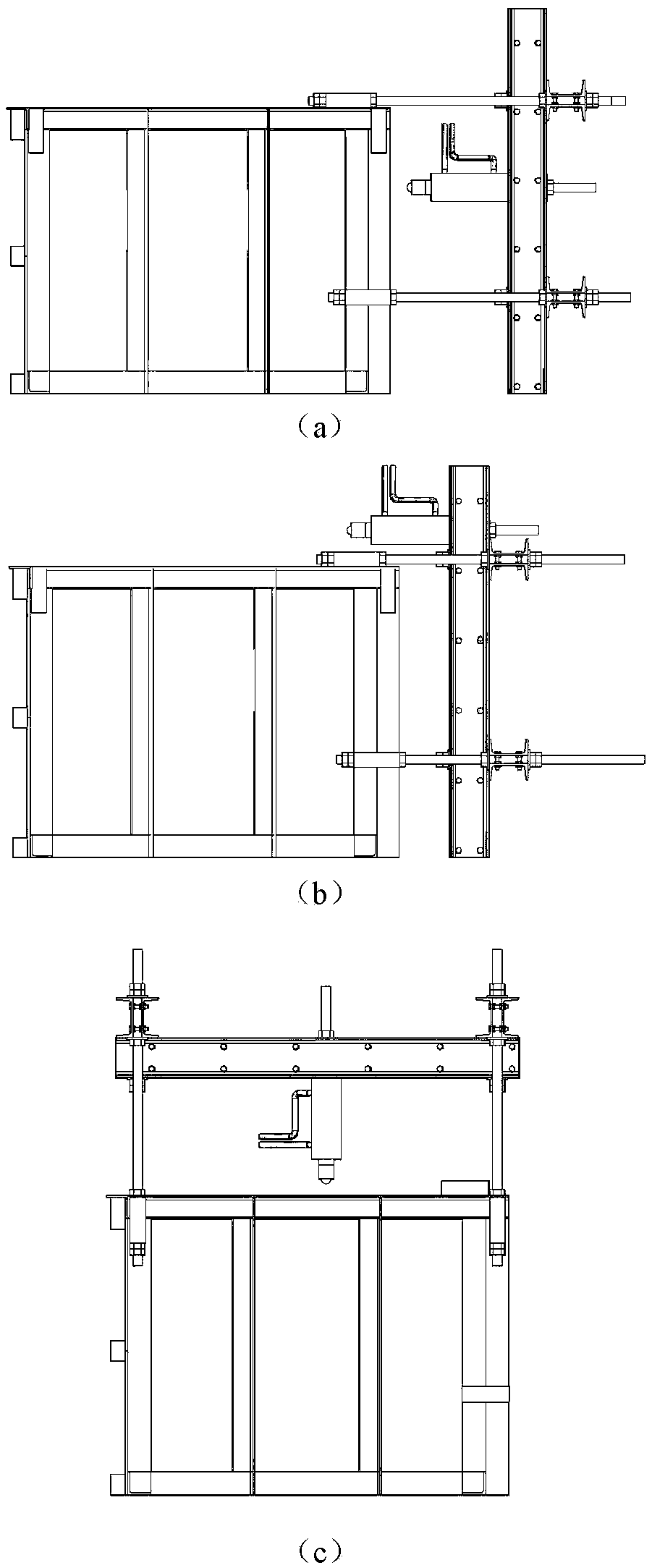

[0034] The multifunctional self-balancing indoor model test chamber is composed of standard section steel through welding and bolt connection. The indoor model test chamber is composed of two systems: Ⅰ counter force loading system, Ⅱ model box body.

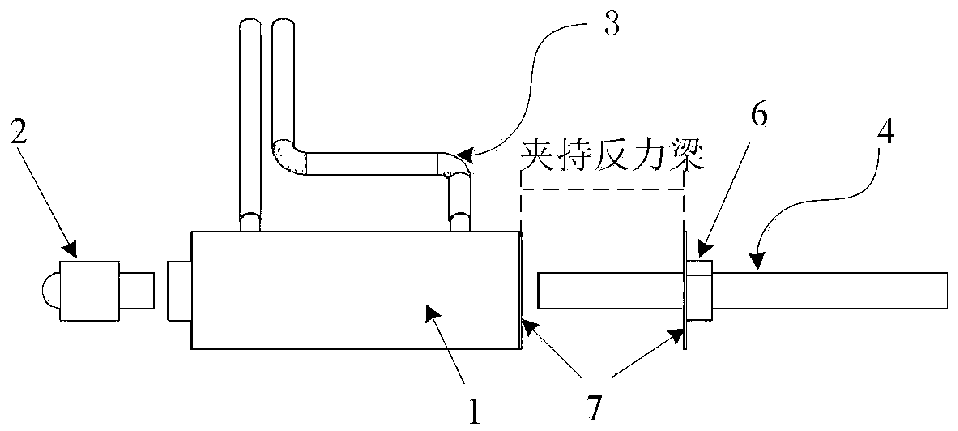

[0035] The reaction loading system can realize three loading modes: the first horizontal loading mode (slope or landslide), the second horizontal loading mode (horizontal force on the pile), and vertical loading mode (vertical force on the pile). According to the specific test plan, other sensors are arranged to monitor related test items.

[0036] The reaction frame is composed of three beams, each beam is made of two channel steel stacked back to back, and the beams of the reaction frame are used between the beams screw connection. The loading unit is composed of four parts: customized two-way hydraulic jack, force sensor, fixing piece and fully automatic hydraulic control system.

[0037] The net size inside the model box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com