Notch defect detection method for flexible IC package substrate line

A packaging substrate and defect detection technology, which is applied in the field of image processing, can solve the problems of sub-pixel accuracy, inability to detect the position of the curve, and complicated methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

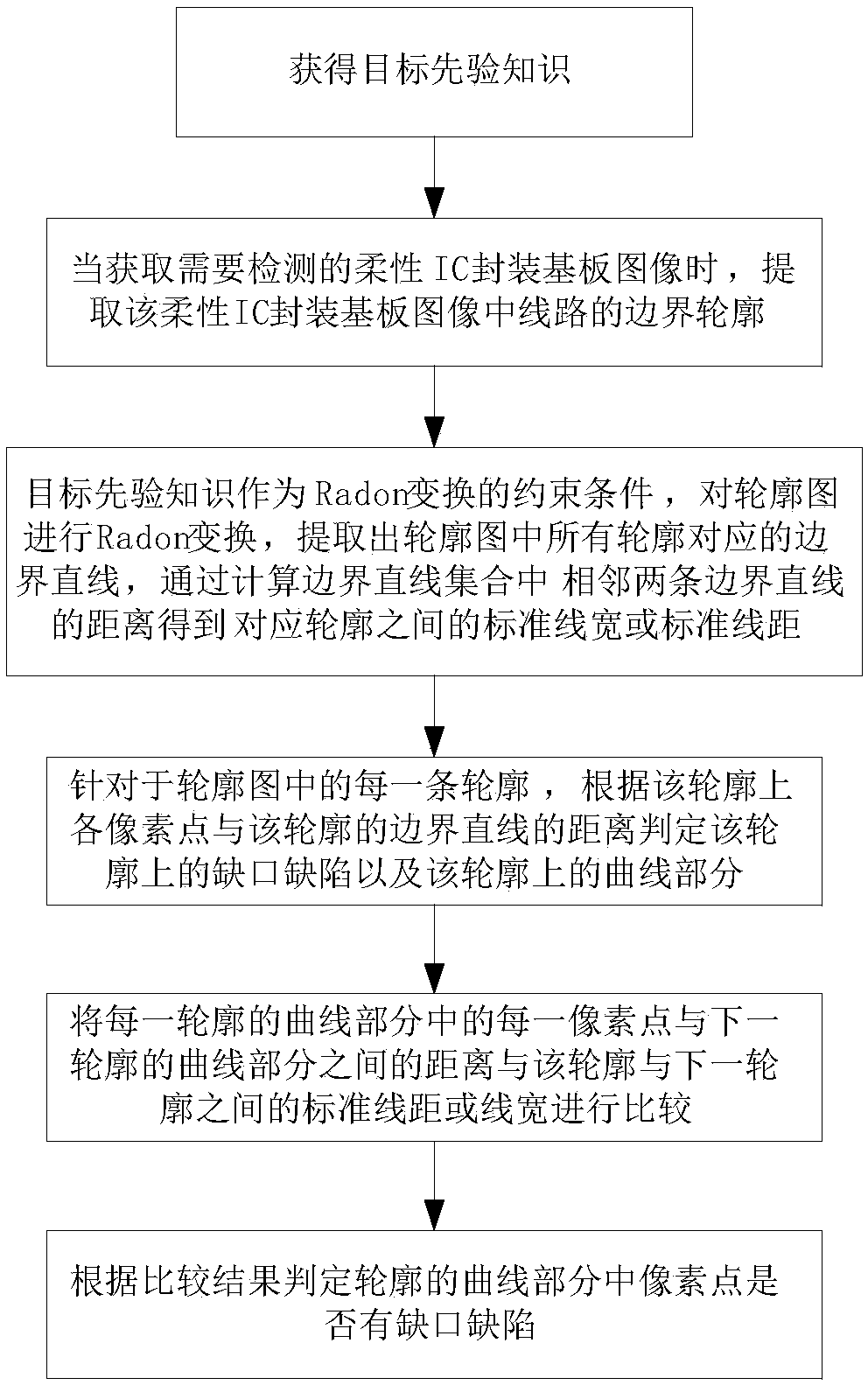

[0071] This embodiment discloses a method for detecting notch defects of flexible IC packaging substrate circuits, such as figure 1 As shown, the steps are as follows:

[0072] Step S1, select a flexible IC packaging substrate of the same type as the flexible IC packaging substrate that needs to detect notch defects, and randomly select some images of the above-mentioned flexible IC packaging substrate, and then pre-learn the circuit features therein to obtain target prior knowledge;

[0073] Wherein in this embodiment, this step pre-learns the circuit features in the flexible IC packaging substrate image, and the specific process of obtaining the target prior knowledge is as follows:

[0074] Statistics the data of the points in the Radon graph corresponding to the two parallel boundary lines in the selected flexible IC package substrate image, and select the maximum inclination angle difference ε° corresponding to the two parallel boundary lines and the value of the center p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com