Stepped shaft outer diameter and gear inner hole comprehensive test tool

A technology of comprehensive inspection fixtures and stepped shafts, which is applied in the direction of measuring devices, instruments, and fluid devices, can solve the problems of no integrated testing equipment, low automation level, and low production efficiency, so as to improve positioning accuracy and detection efficiency. Improved detection efficiency and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

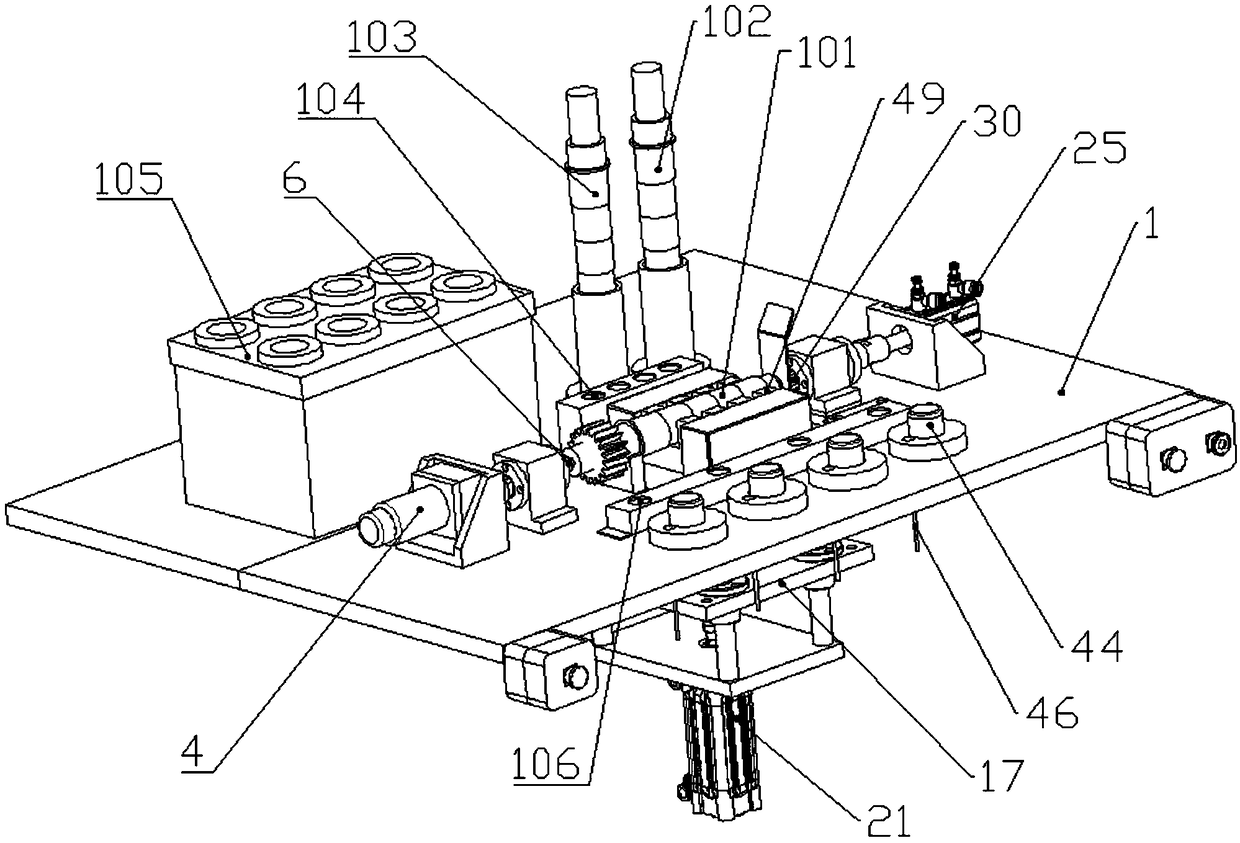

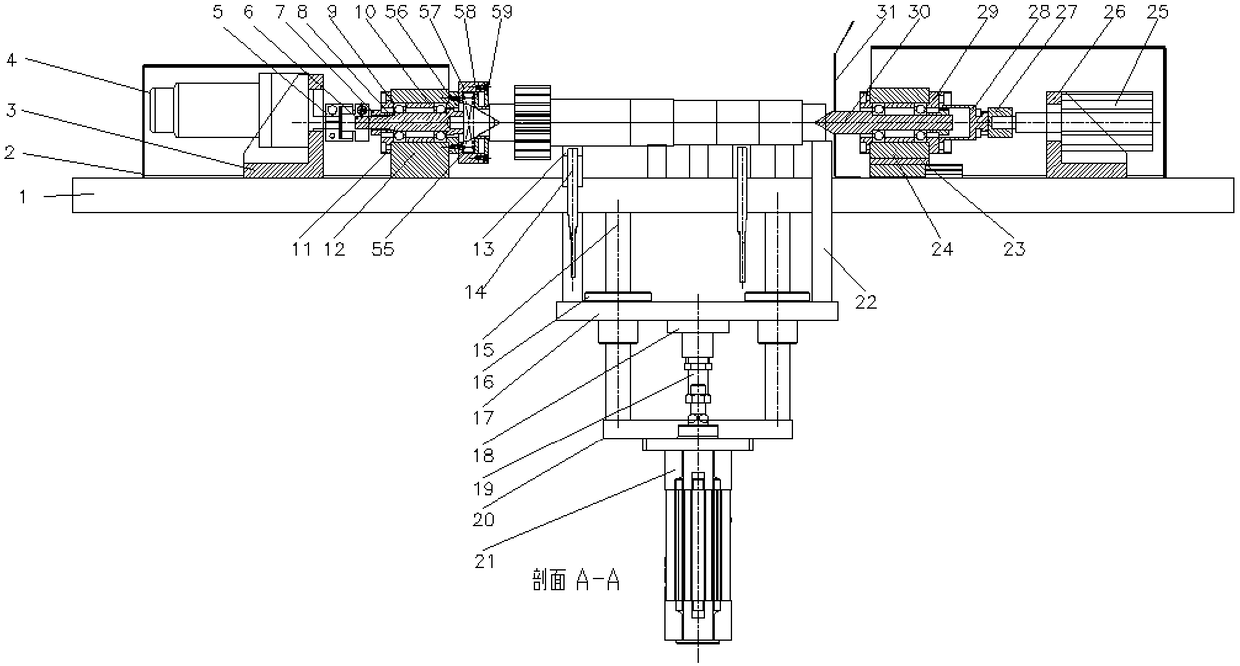

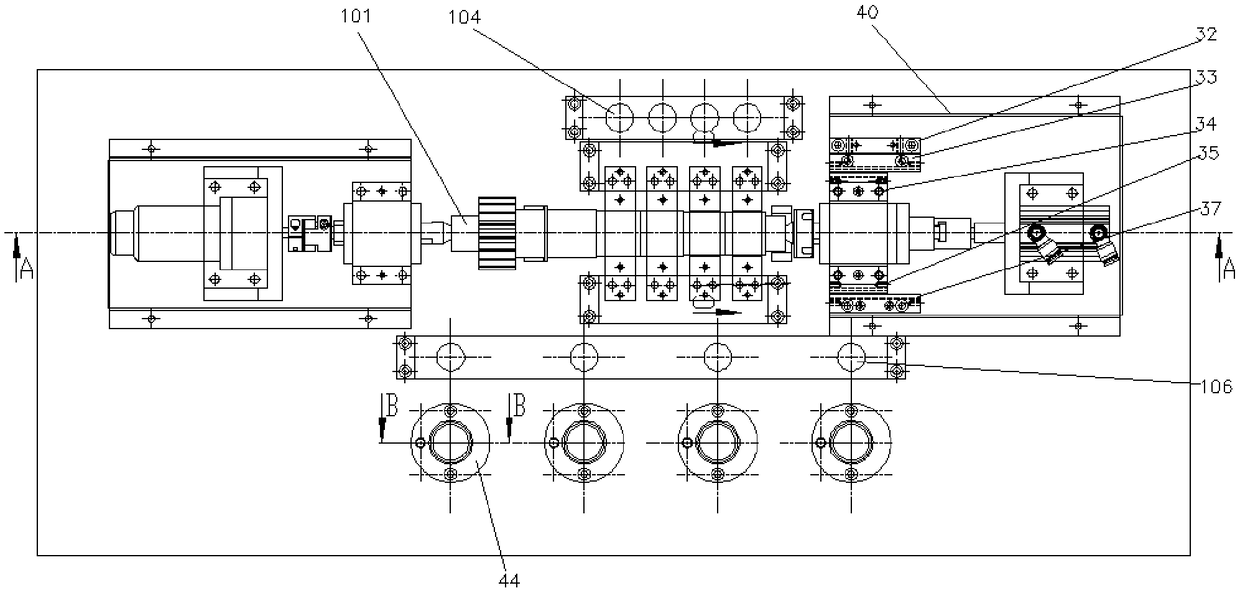

[0026] Such as figure 1 , 2 , 3, 4, and 5 show a comprehensive inspection tool for stepped shaft outer diameter and gear inner hole, including a positioning component for stepped shaft positioning, a feeding component for stepped shaft feeding, and a stepped shaft outer diameter Four outer diameter measuring components for measurement, four inner hole measuring components for gear inner hole detection. It can be seen that the motor 4 is installed on the motor bracket 3, the motor bracket 3 and the base plate 1 are connected by four bolts, the left center 6 is connected with the motor 4 through the coupling 5, and the left center 6 is installed from left to right in turn There are nut 7, retaining ring one 8, angular contact ball bearing 9, and retaining ring two 10 are installed between the angular contact bearing 9. The left center 6 and the angular contact ball bearing 9 are connected by interference fit, and the angular contact ball bearing 9 is installed at the left end The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com