Spiral blade centrifugal fan

A centrifugal fan and helical blade technology, applied in the field of centrifugal fan and helical blade centrifugal fan, can solve the problems of axial length limitation, large pressure loss and low efficiency of ordinary centrifugal fans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

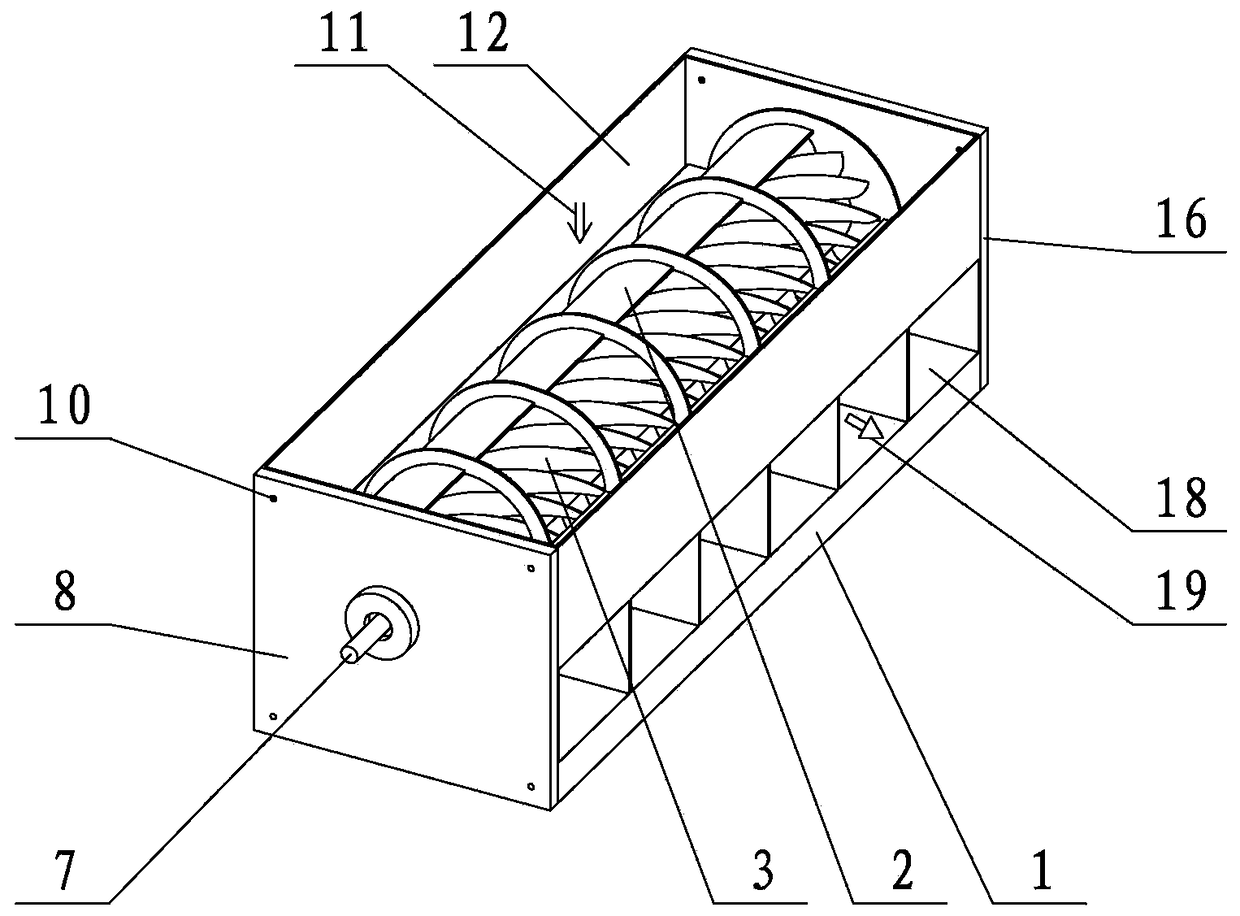

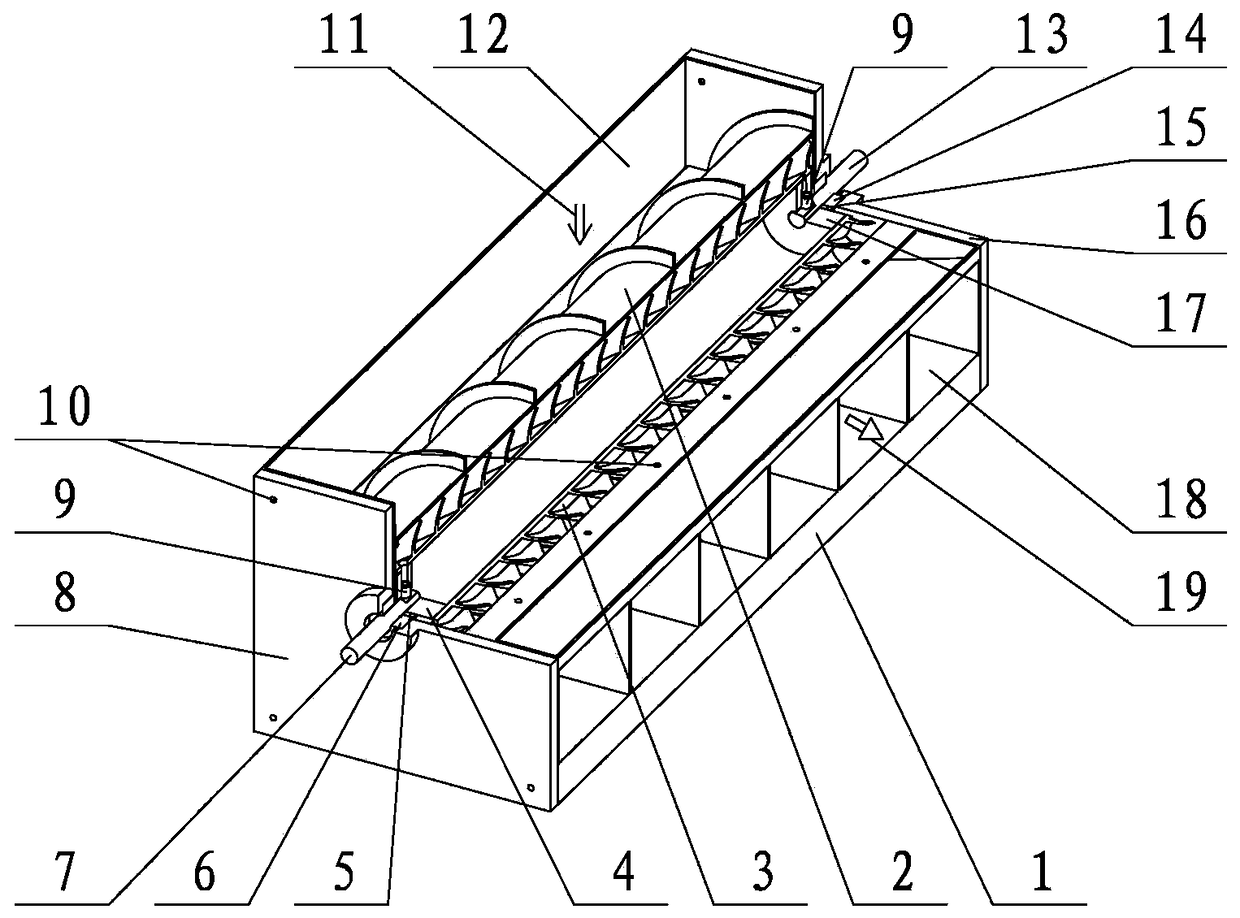

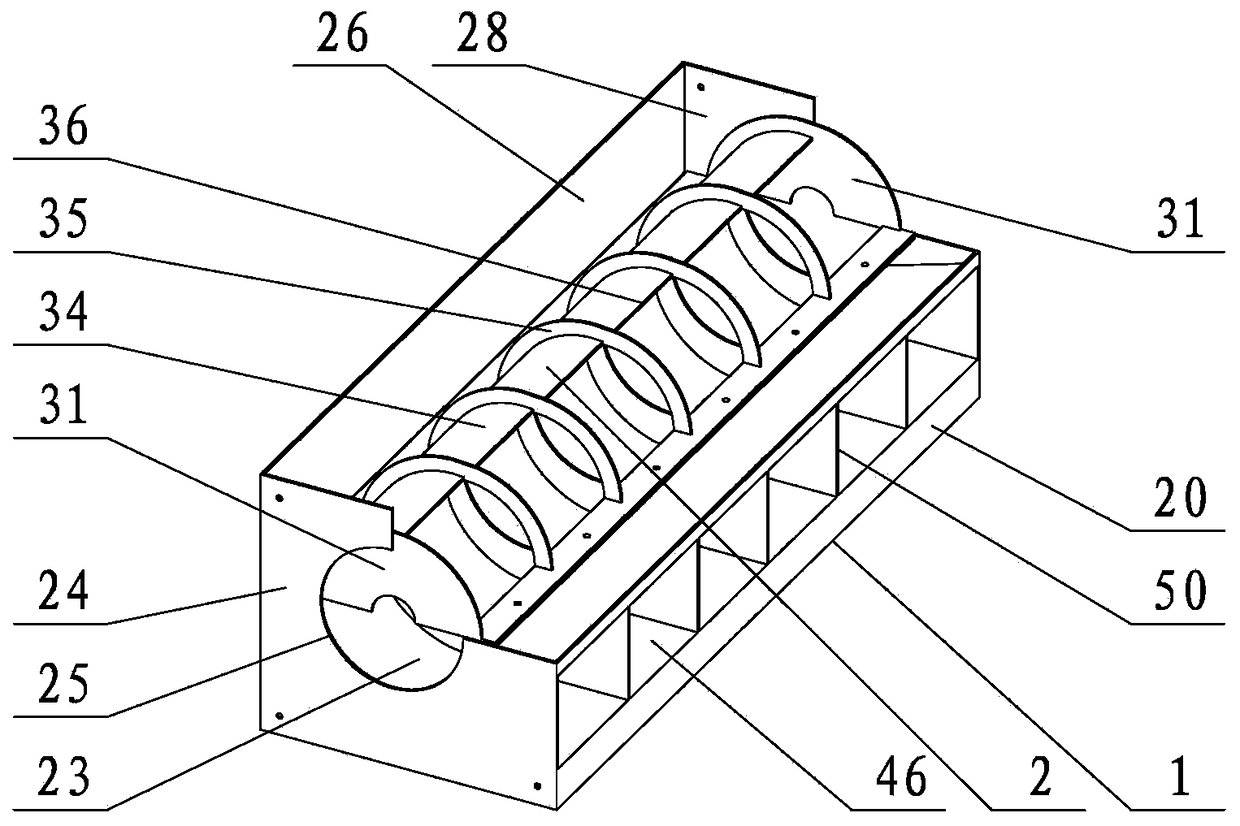

[0037] The present invention is further described below in conjunction with accompanying drawing.

[0038] refer to figure 1 , figure 2 , Figure 12 , Figure 15 , The centrifugal fan includes a base part, a guide volute 2, and an impeller part. The guide volute 2 is installed in the inner cavity of the base part, the impeller part is installed in the inner cavity of the guide volute 2, and the motor is installed in one axial end of the base part. When the centrifugal fan is in operation, the motor drives the impeller 3 of the impeller part to rotate. Under the action of centrifugal force, the airflow is accelerated during the process of flowing along the helical impeller channel 40 of the impeller 3, and the airflow in the impeller channel 40 flows from the guide When the front end 36 of the flow volute plate enters the inner cavity of the guide volute 2, the cross-sectional area of the volute cavity 46 on the radially inner side of the guide volute 2 and the volute pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com