Internal thread cyclone forming method and device

A molding device and molding method technology, applied in the field of manufacturing equipment, can solve problems such as difficult processing and restrictions, and achieve the effect of high efficiency and increased axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings, and the purpose and effect of the present invention will become more obvious.

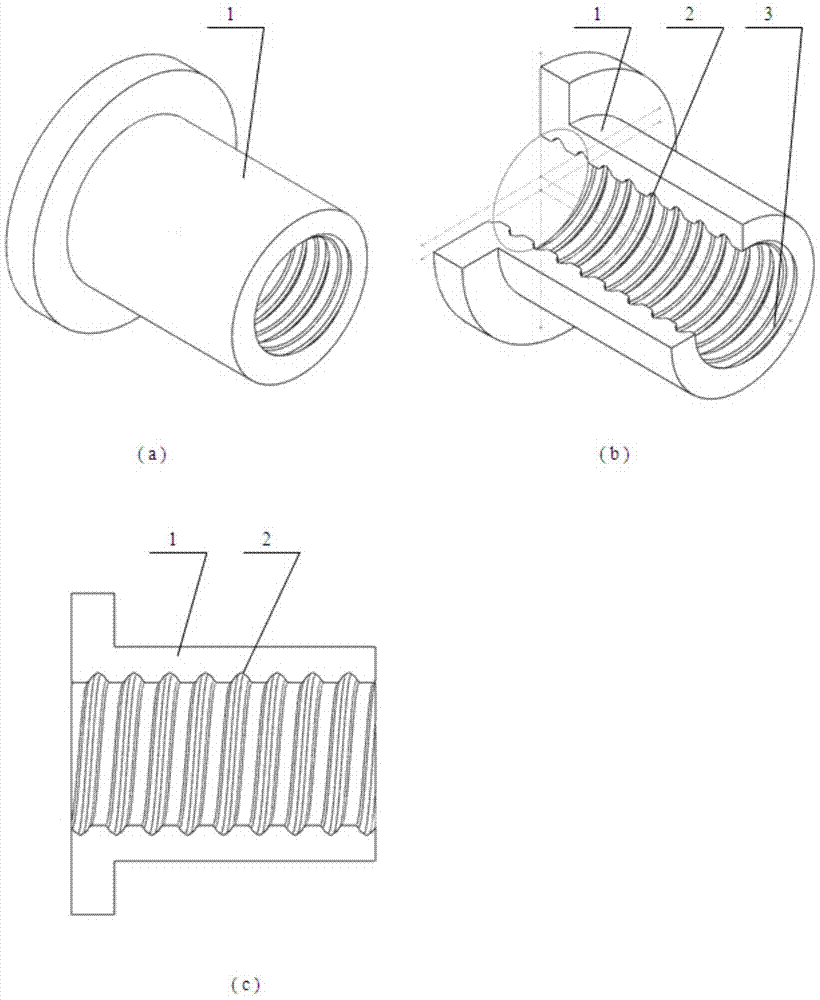

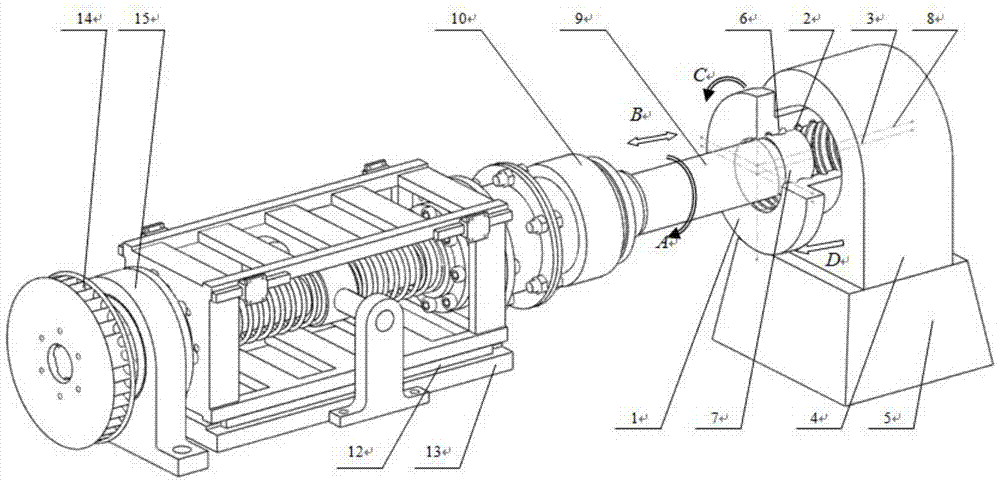

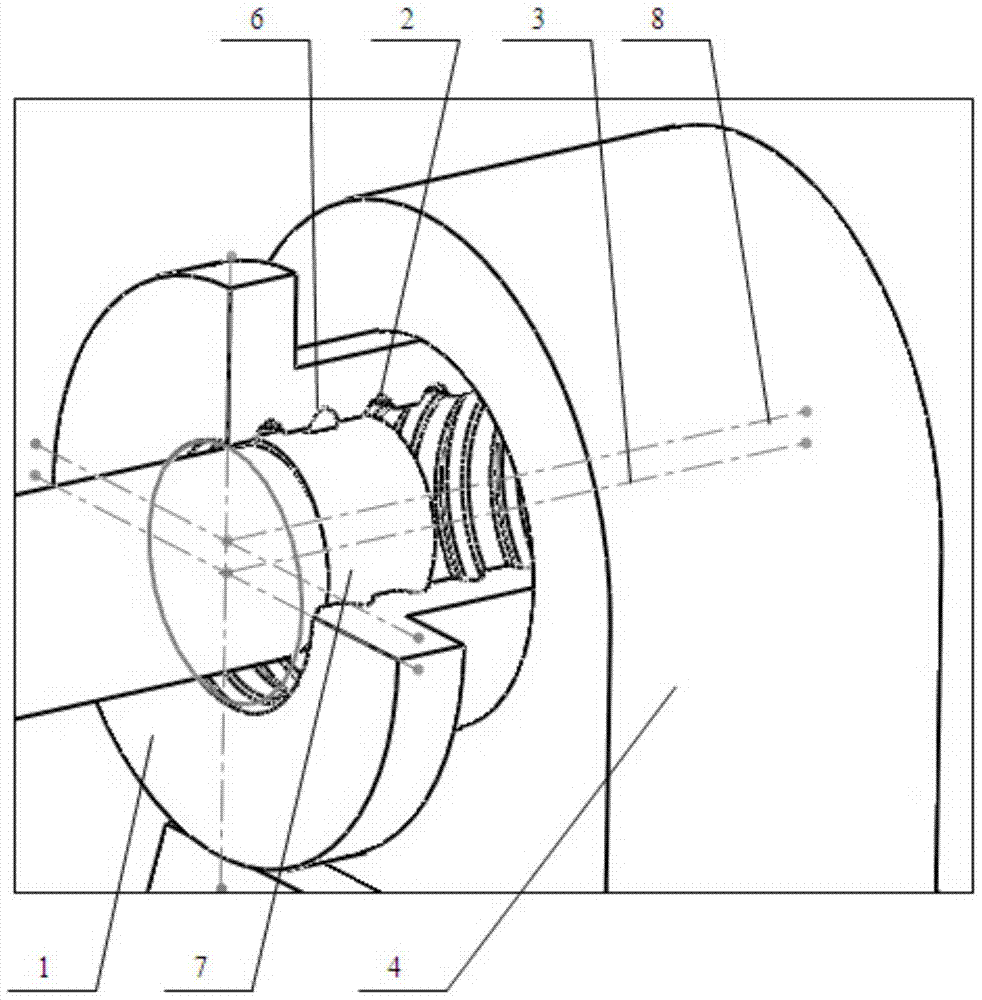

[0045] First explain the situation of the workpiece. The shape of the workpiece is cylindrical, and there is a round hole inside. There is a thread groove with a fixed pitch along the cylindrical helix in the round hole. The cylindrical helix has an axis. On the section surface passing through the axis, the thread The slots can be in different shapes, such as trapezoidal, arcuate, etc. In the ball nut of the transmission element ball screw pair, the cross-sectional shape of the internal thread raceway is a double arc shape. figure 1 The case of a ball nut is shown, including workpiece 1 (ball nut), internal thread raceway 2, and workpiece axis 3. In order to efficiently and accurately process the internal thread raceway, the internal thread cyclone forming method and device of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com