Baffle suitable for outer edge dehumidification and application method thereof

A technology of outer edge and baffle, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of fast steam flow and large steam leakage, so as to improve efficiency, reduce steam flow speed, and ensure water drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

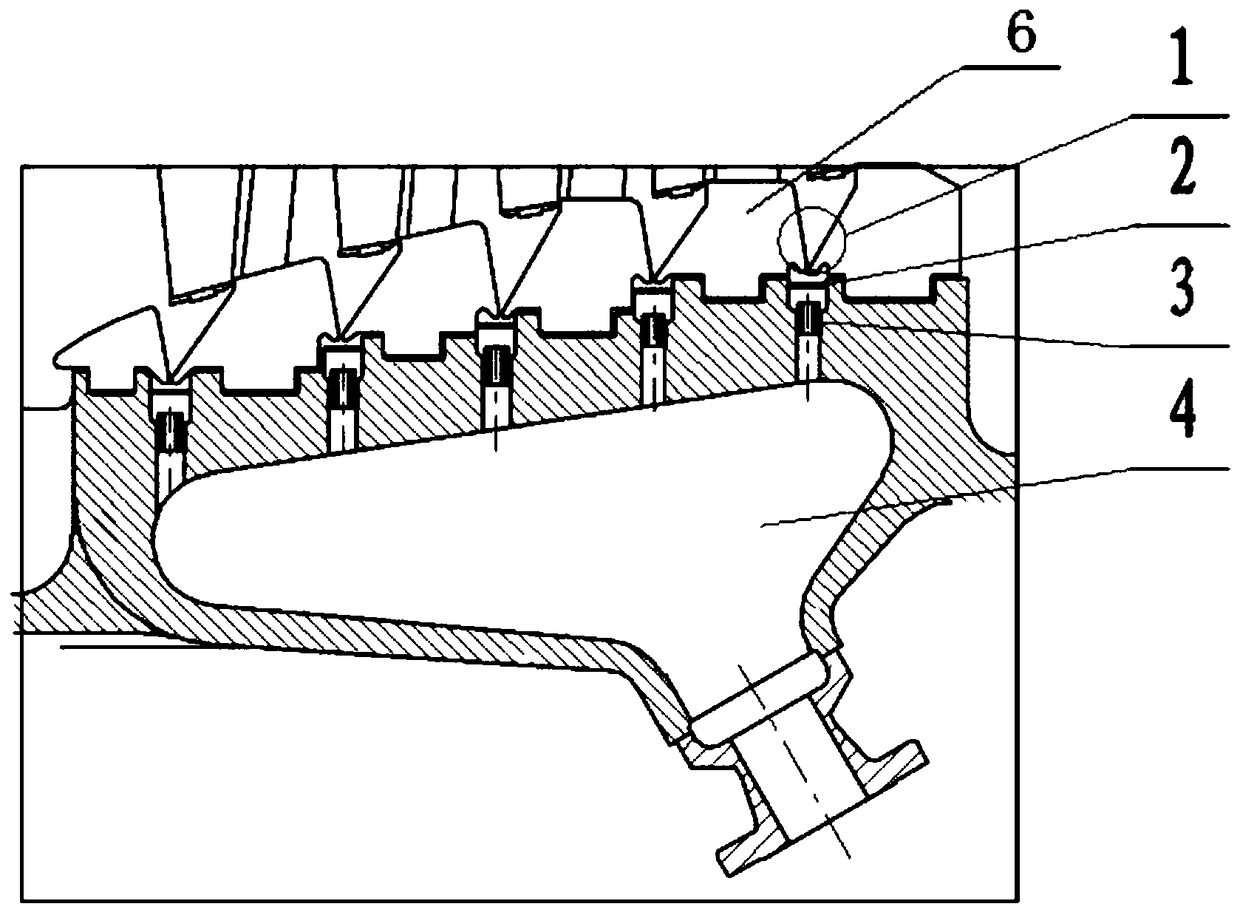

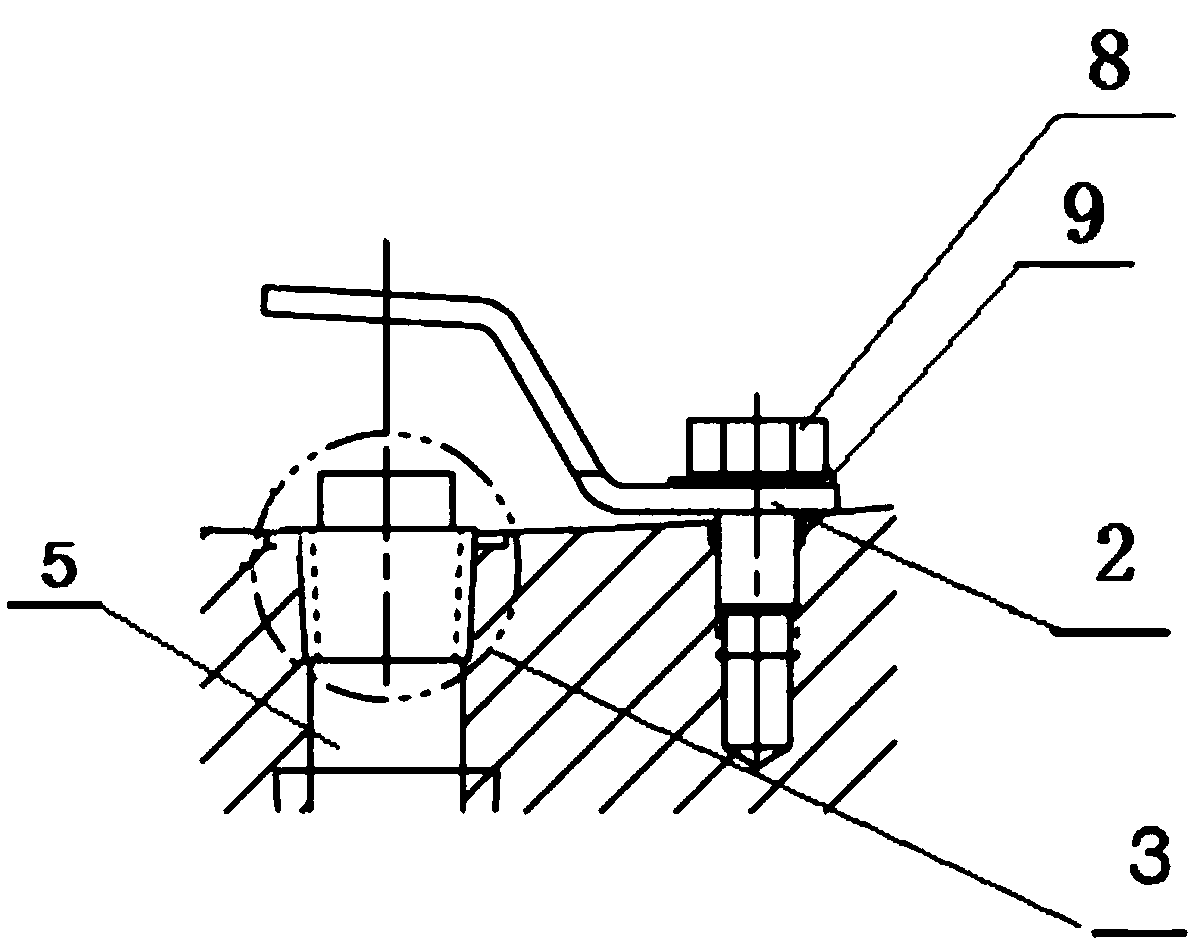

[0026] Specific implementation mode one: combine Figures 1 to 3 Describe this embodiment, a baffle adapted to dehumidification on the outer edge of this embodiment, which includes a baffle 2, a drain valve 3 and a drain chamber 4;

[0027] The upper end of the hydrophobic chamber 4 is opened with a plurality of threaded through holes 5, and the upper surface of the hydrophobic chamber 4 is an inclined plane;

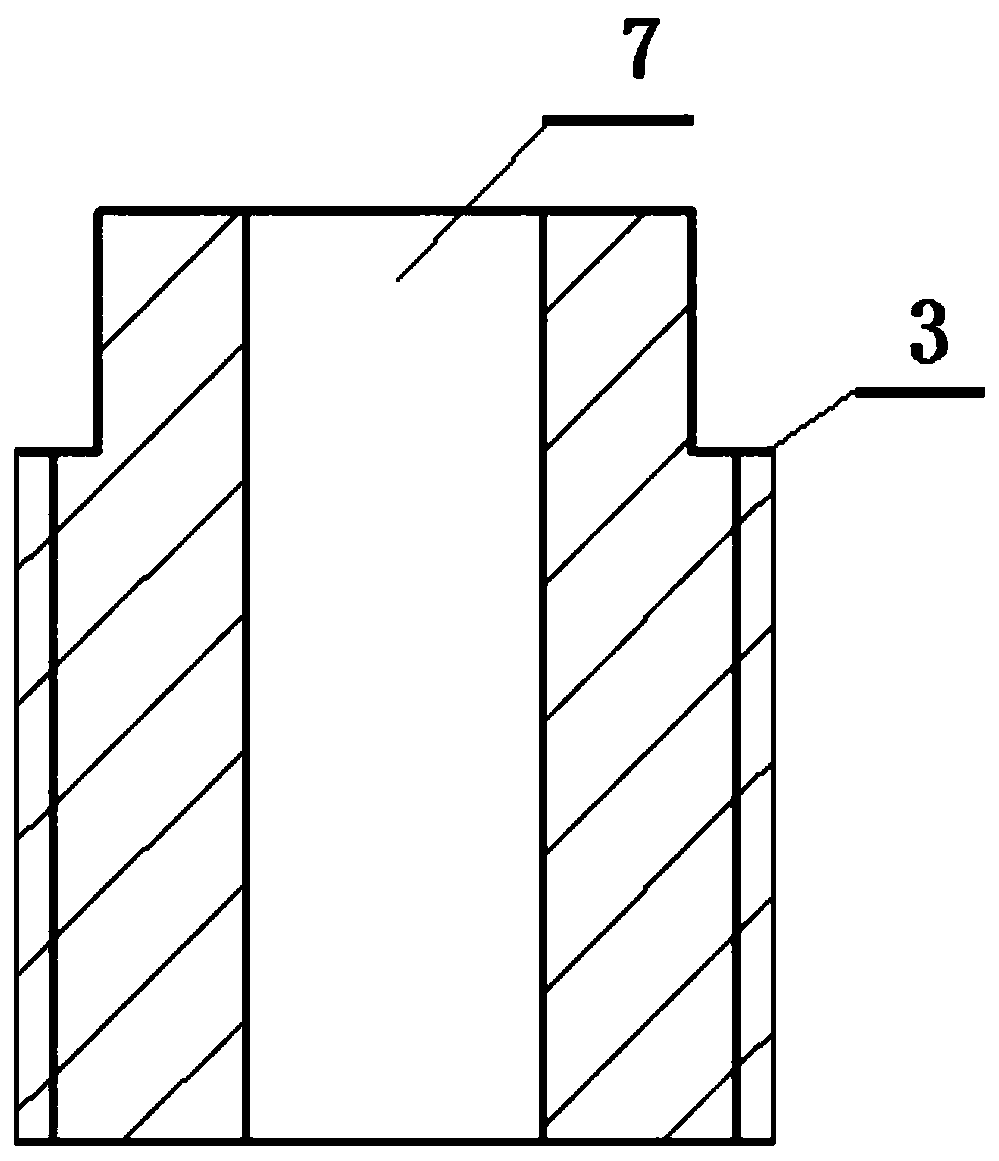

[0028] A through hole 7 is provided in the middle of the steam trap 3, and an external thread is provided on the outer wall; the steam trap 3 is threadedly connected with the threaded through hole 5;

[0029] The baffle 2 has a "Z" shape structure, the end surface of one side of the baffle 2 is attached to the upper surface of the hydrophobic chamber 4, and the baffle 2 is fixed on the hydrophobic chamber 4 by bolts 8; the other side of the baffle 2 is located on the hydrophobic chamber 4. above valve 3.

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figures 1 to 3 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: a plurality of blades 6 of the last few stages are respectively arranged on the upper surface of the hydrophobic chamber 4 on the left and right sides of the threaded through hole 5; An outer edge dehumidification zone 1 is formed between the outer edges of the blades 6 .

[0031] Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination Figures 1 to 3 This embodiment is described. The difference between this embodiment and the first embodiment is that the outer edge dehumidification zone 1 is located above the baffle plate 2 .

[0033] Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com