Feeding mechanism for core sampling drill

A feeding mechanism and core sampling technology, which is applied in the direction of extracting undisturbed core devices and earthwork drilling and mining, can solve the problems of low degree of automation, harsh working environment, and low sampling efficiency, and achieve a simplified structure, reduced construction personnel, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

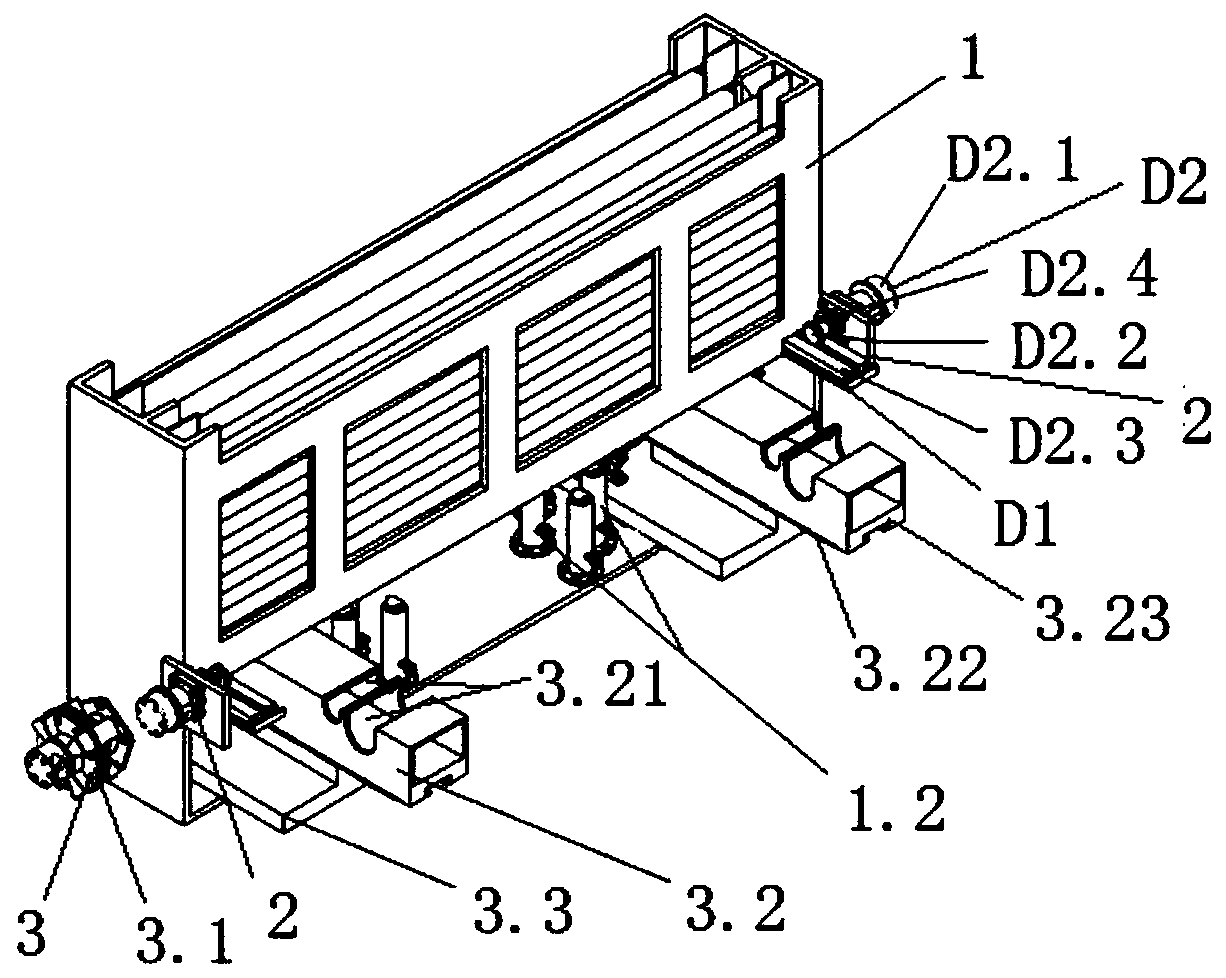

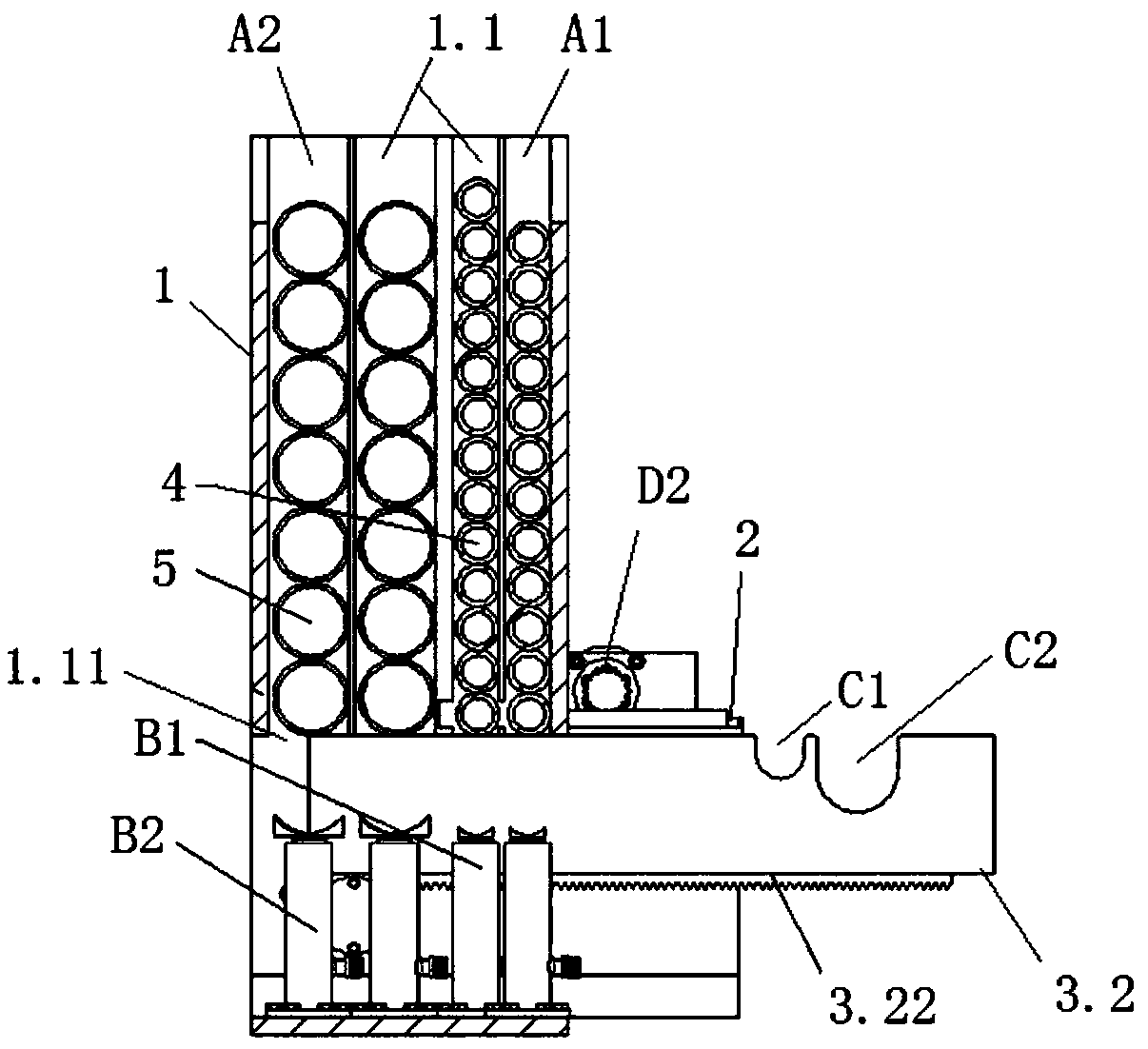

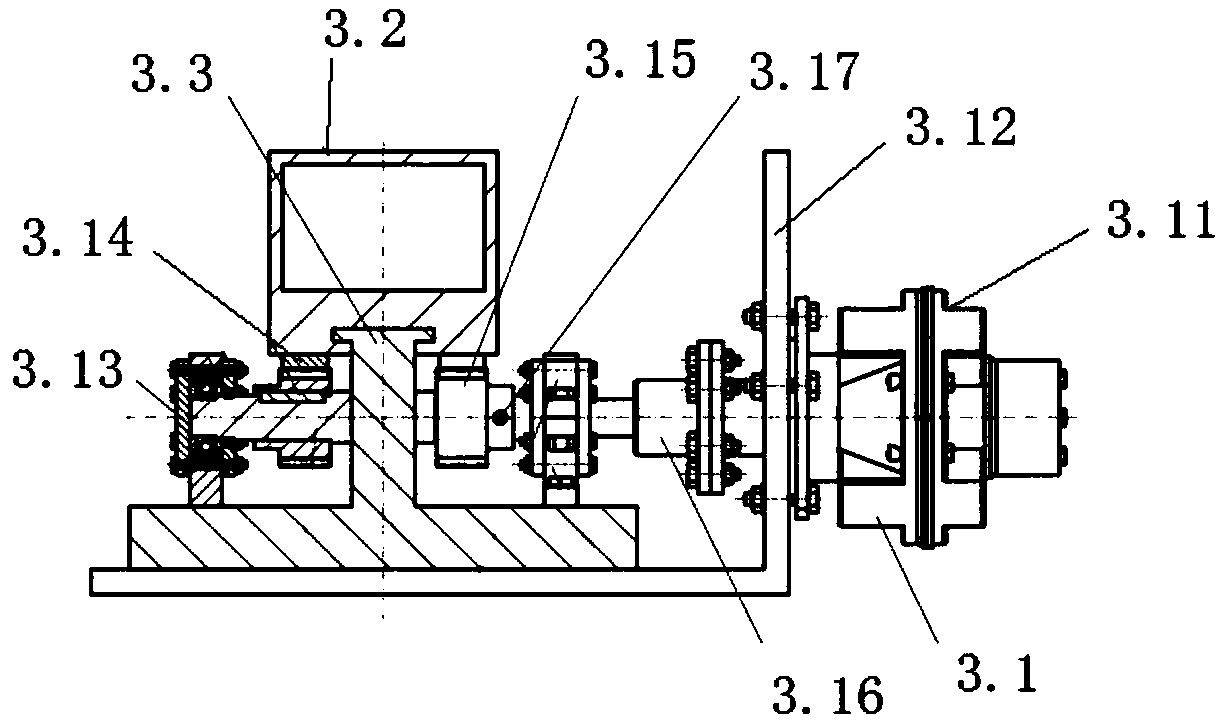

[0033] A feeding mechanism for a core sampling drilling rig, specifically a feeding mechanism capable of transporting drill pipe 4 and casing 5 at the same time, including a storage mechanism 1, a support mechanism 2 and a delivery mechanism 3, see Figure 1-Figure 3 ,Details are as follows:

[0034] The storage mechanism 1 includes a body, a housing chamber group and a jacking assembly, the housing chamber group is separated by partitions arranged inside the body, and the housing chamber group includes four housing chambers 1.1 arranged side by side, two of which are housing chambers. The drill pipe accommodation chamber A1 of the drill pipe, and the other two are casing chamber accommodation chambers A2 for accommodating the casing pipe. The drill pipe accommodation chamber A1 includes a material outlet 1.11 through which a drill pipe can pass, and the casing accommodation chamber A2 includes a material outlet 1.11 through which a casing pipe can pass. The jacking assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com