Sliding window with automatic dust removal function

A technology of automatic dust removal and sliding windows, which is applied in the field of windows, can solve the problems of limited ventilation area, harm to health, difficulty in sliding windows, etc., and achieve the effect of reducing troubles and delaying dust discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

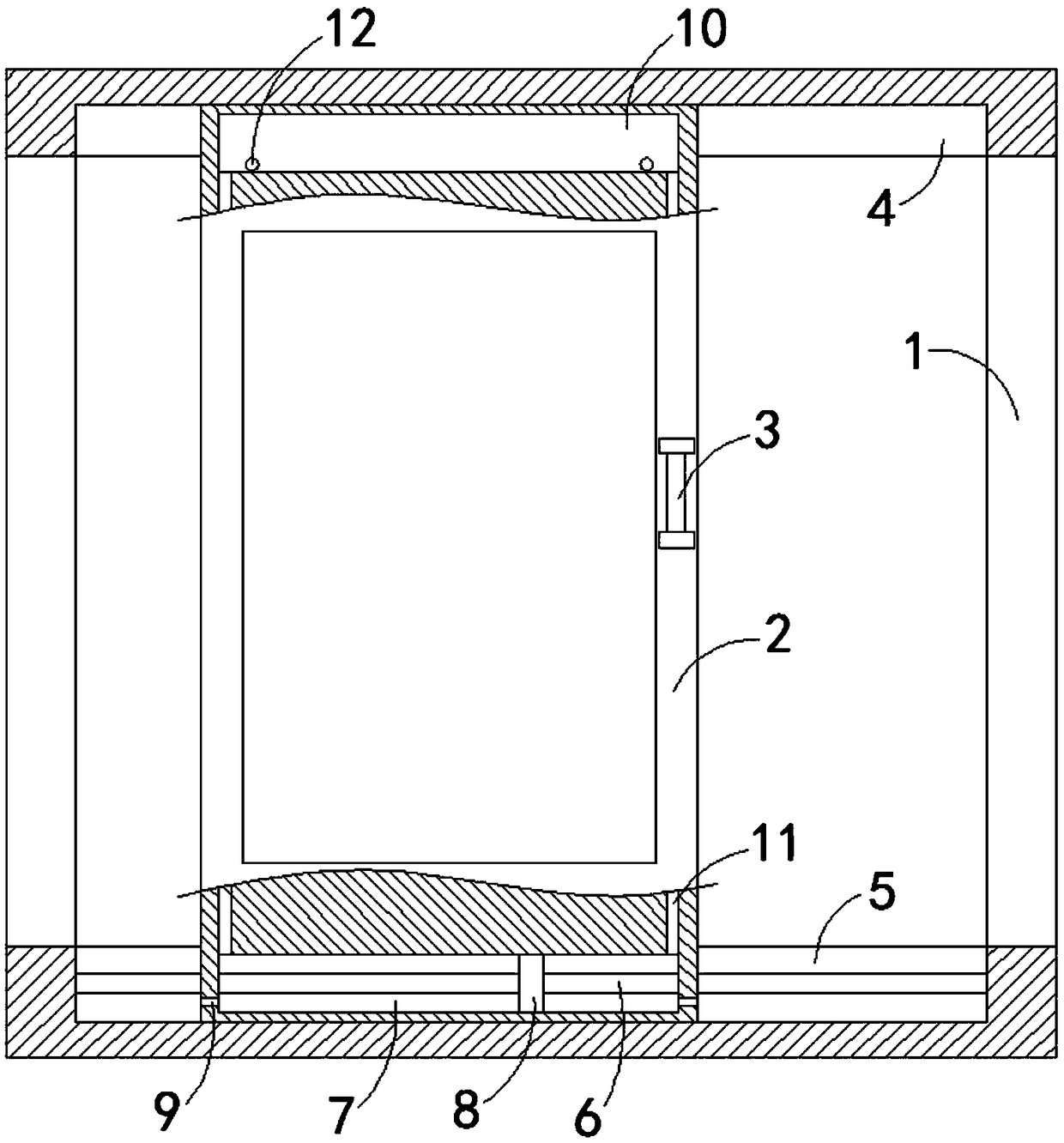

[0018] Such as figure 1 As shown, a sliding window with automatic dust removal function includes a window frame 1 and a form 2. It should be noted that the lower end of the form 2 is fixedly connected with a sealing top (not shown in the figure), and the sealing top ensures that the window 2. At the same time of airtightness, in the process of moving with the window 2, it will also sweep from the bottom surface of the groove to sweep up the dust adsorbed on the bottom surface of the second sliding groove 5, so that the dust in the second sliding groove 5 is easier to clean. Sucked away by the air flow, the side wall of the form 2 is fixedly connected with a handle 3, the inner top surface and the inner bottom surface of the window frame 1 are respectively provided with a first slide groove 4 and a second slide groove 5, and the upper and lower sides of the form 2 The ends are respectively located in the first sliding groove 4 and the second sliding groove 5, and the second sli...

Embodiment 2

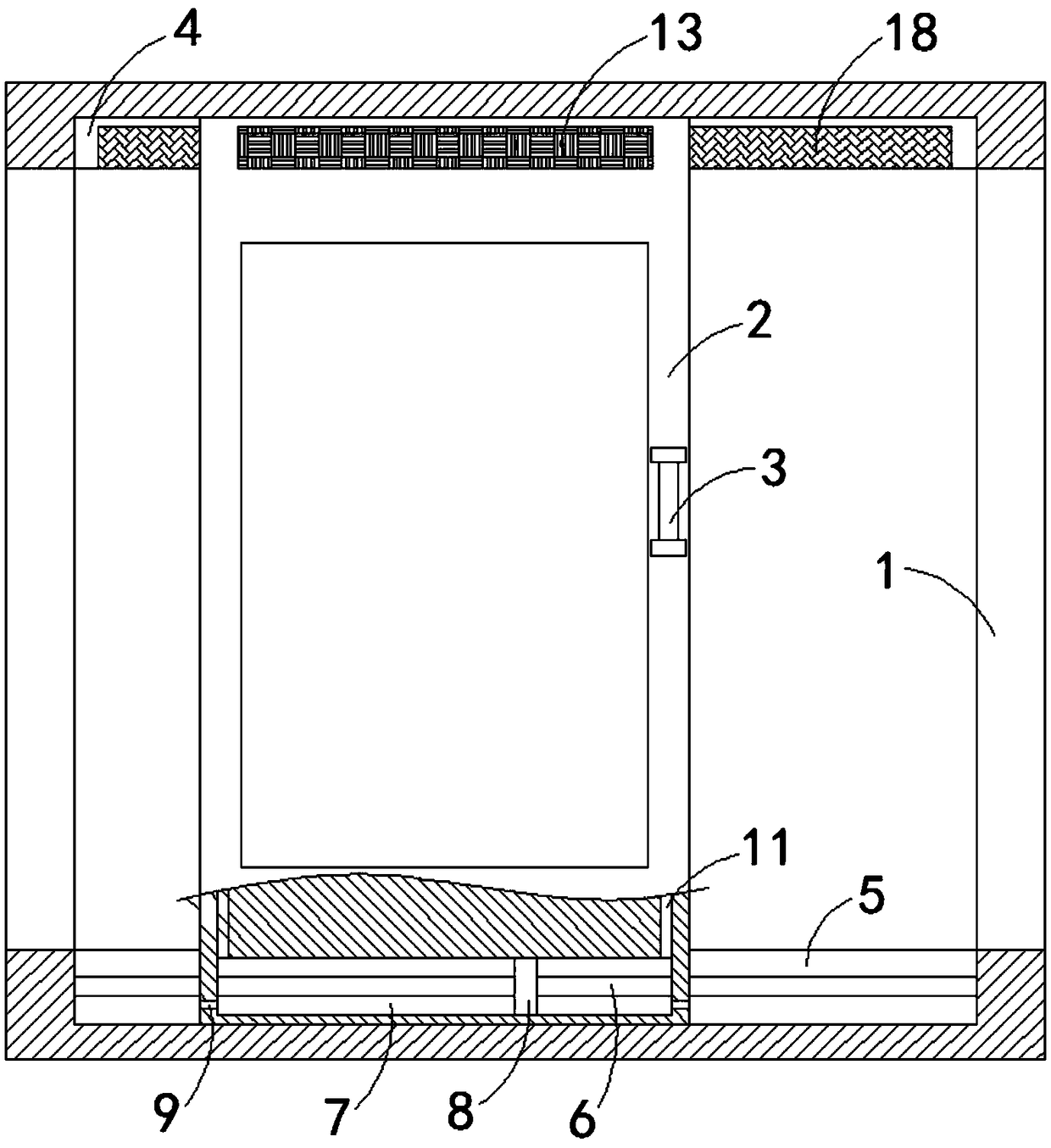

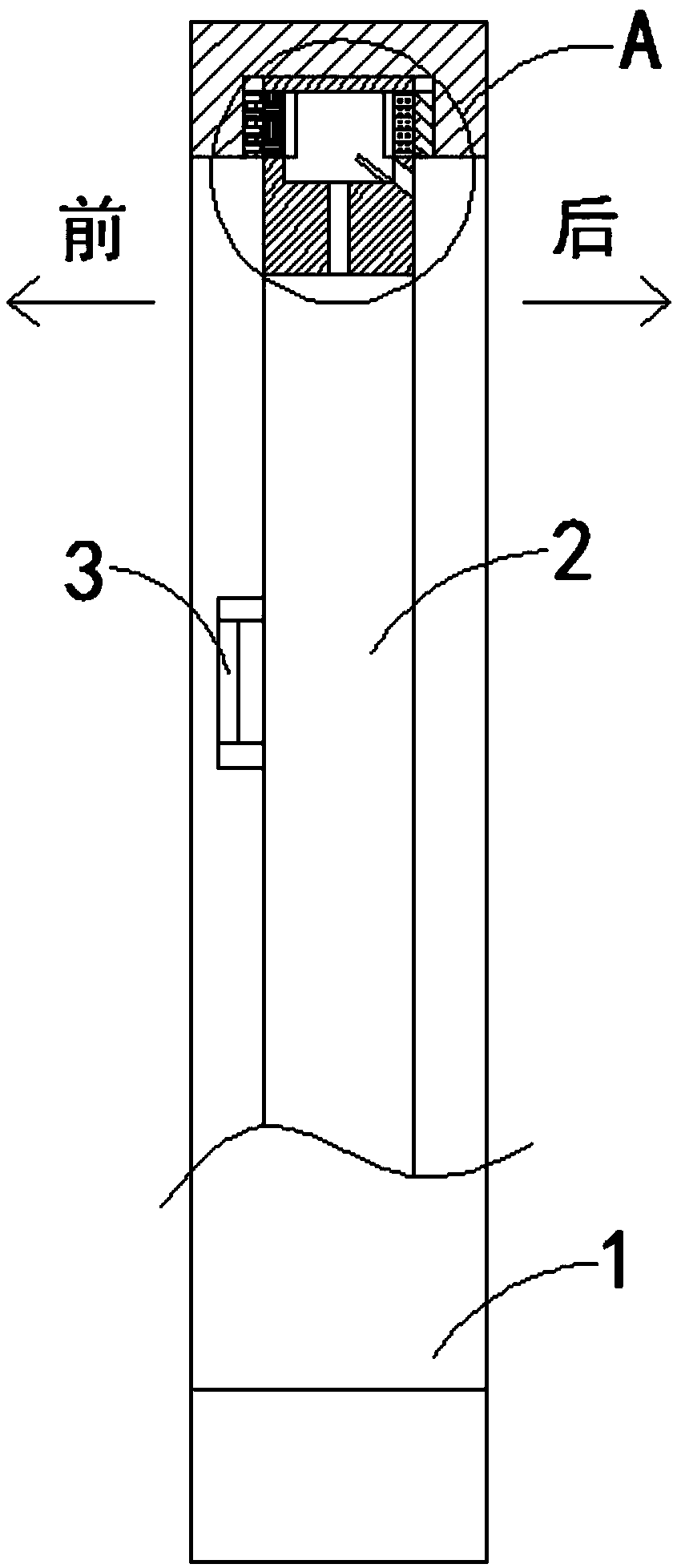

[0022] Such as Figure 2-4 As shown, the difference between this embodiment and Embodiment 1 is that: the front and rear side walls of the exhaust chamber 10 are respectively provided with a first opening and a second opening, the first opening is fixedly connected with a glass mesh plate 13, the second A rubber net plate 14 is fixedly connected in the opening, a first induction plate 15 and a second induction plate 16 are respectively fixedly connected on the opposite side walls of the glass net plate 13 and the rubber net plate 14, and the front and rear inner walls of the first slide groove 4 are respectively A silk layer 17 and a fur layer 18 are fixedly connected, and the exhaust port 12 is arranged obliquely downward from the inside to the outside. The angle of inclination is the same.

[0023] In this embodiment, when the window 2 moves, friction will be generated between the glass net plate 13 and the silk layer 17, the rubber net plate 14 and the fur layer 18. Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com