Automobile self-sucking door lock

A self-priming and door lock technology, which is applied in vehicle locks, electric locks, building locks, etc., can solve the problems of large closing force, loud noise, and the door cannot be closed, and achieve the effect of easy closing and locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below based on the drawings and specific embodiments.

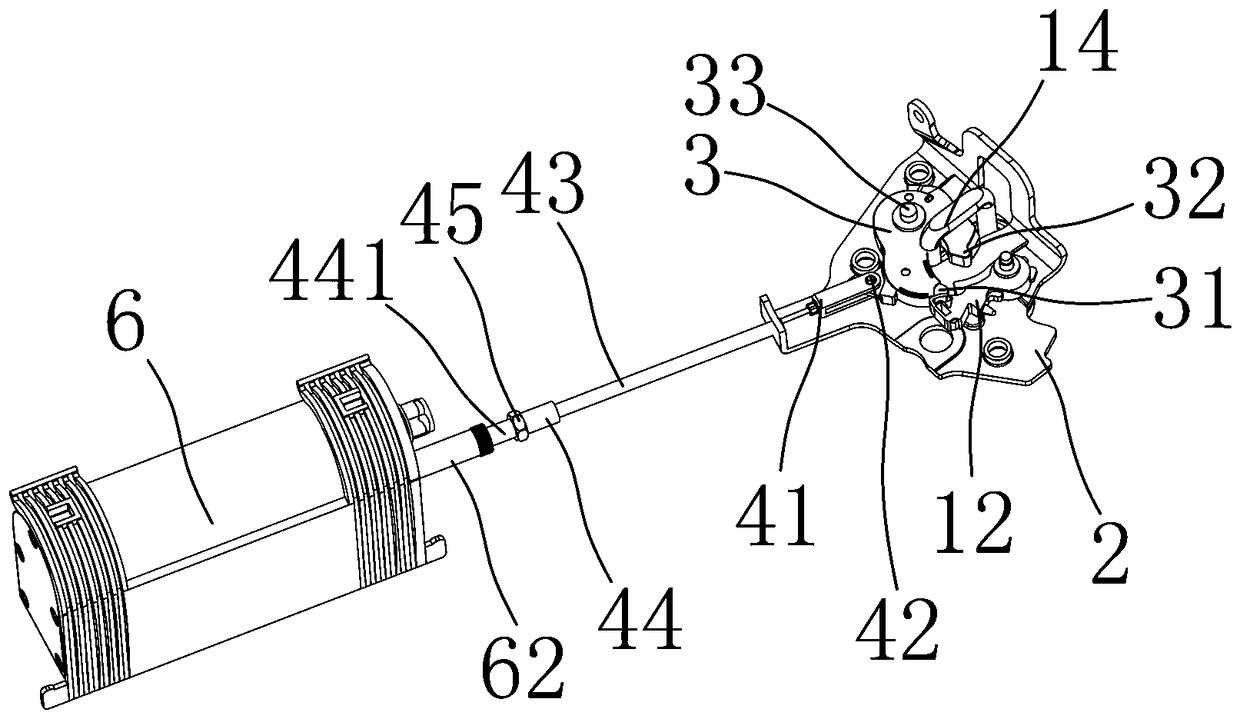

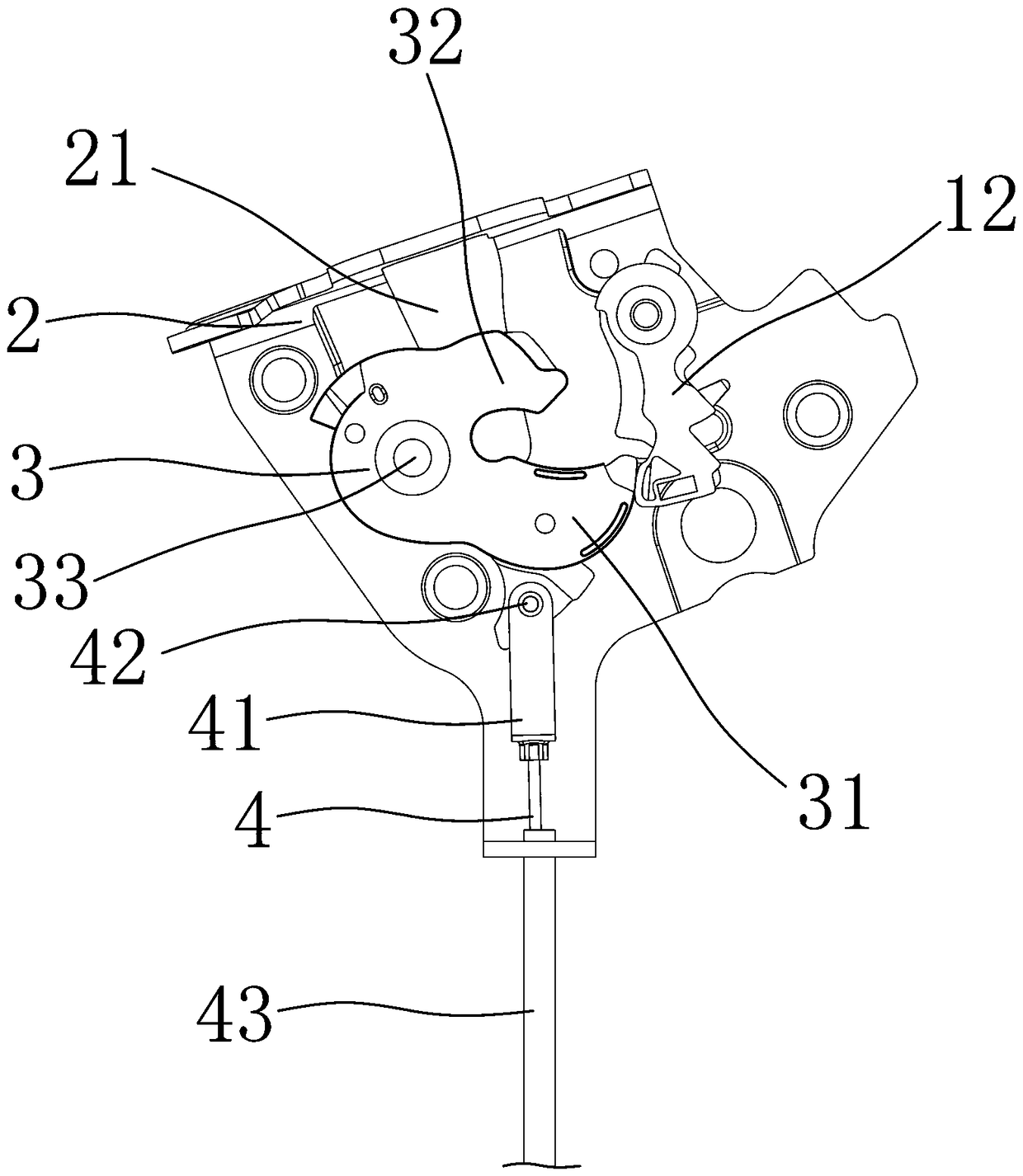

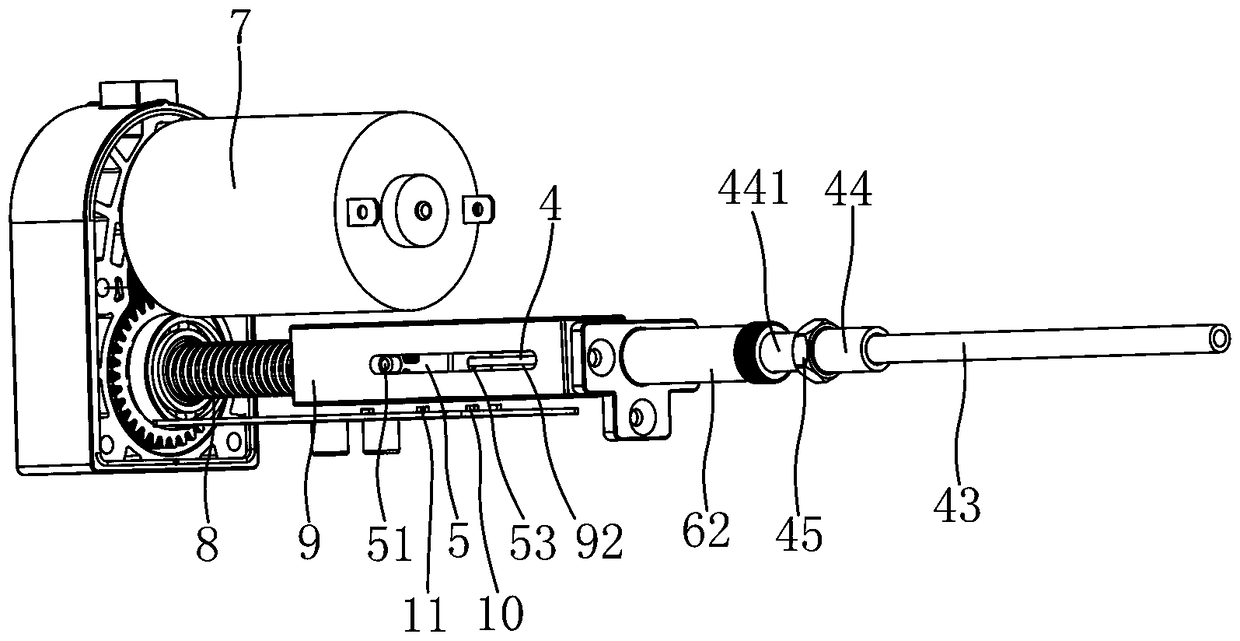

[0034] by Figure 1 to Figure 9 As shown, a self-priming door lock for an automobile of the present invention includes a locking mechanism, a driving mechanism, a first position sensor 10 and a second position sensor 11. The locking mechanism includes a fixing plate 2, and the fixing plate 2 is formed with a slot 21 , The lock tongue 3 is rotatably fixed on the fixed plate 2, the lock tongue 3 is C-shaped, one end of the lock tongue 3 is the linkage end 31, the other end of the lock tongue 3 is the locking end 32, and the linkage end 31 is linked with the cable 4, The end of the pull wire 4 away from the locking mechanism is fixed to the slider 5. The door is provided with a locking hook 14 in an enclosed shape.

[0035] The difference between the locking mechanism of the present invention and the existing locking mechanism is that the lock tongue 3 is linked with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com