Heat preservation system of fine aggregate bin

A thermal insulation system and fine aggregate technology, which is applied in the field of thermal insulation system of fine aggregate silo, can solve the problems of inability to meet the rapid development of engineering construction, insignificant thermal insulation effect, unfavorable environmental protection, etc., and achieve flexible conversion of automatic control mode and thermal insulation effect. Significant, labor-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

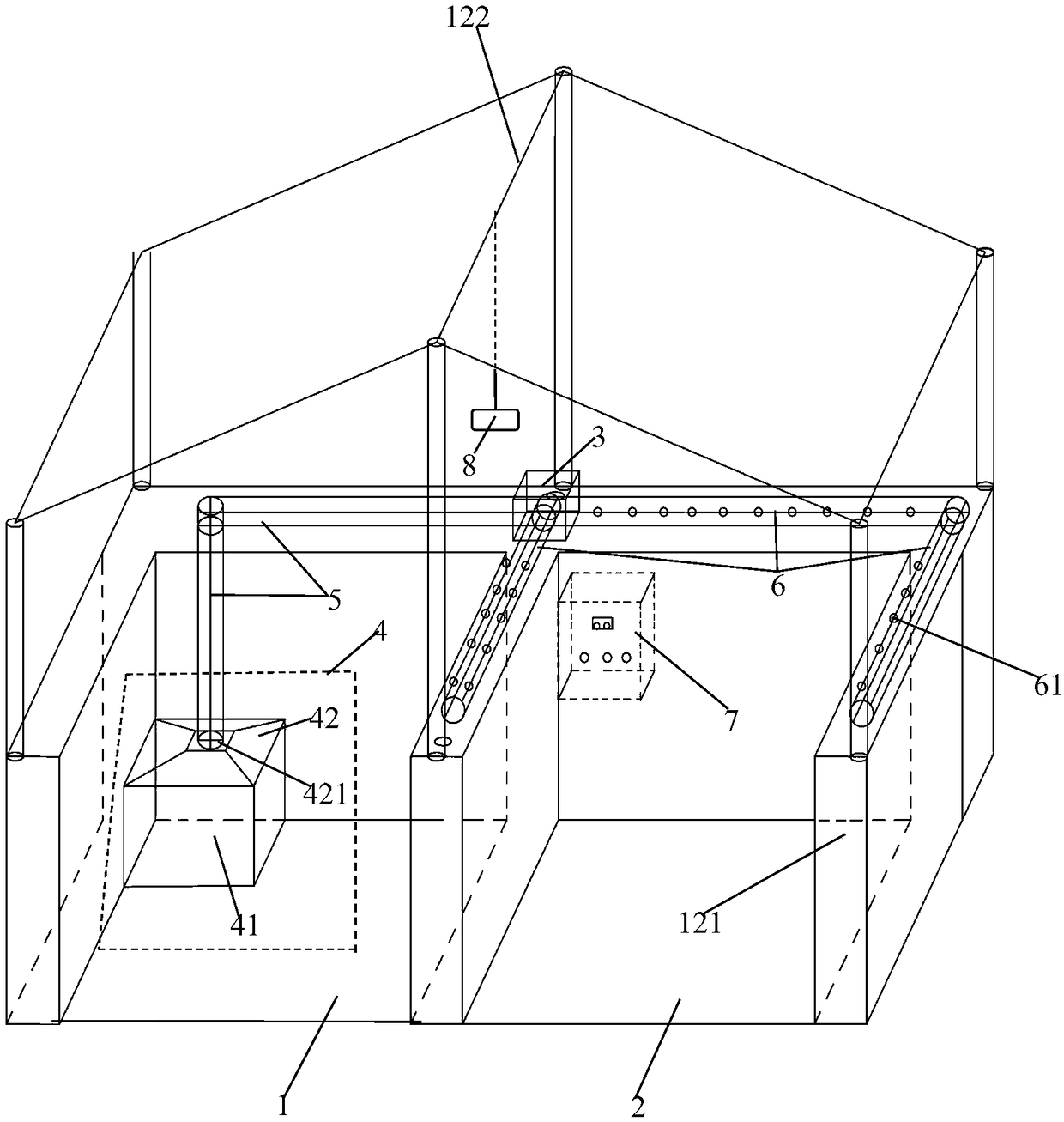

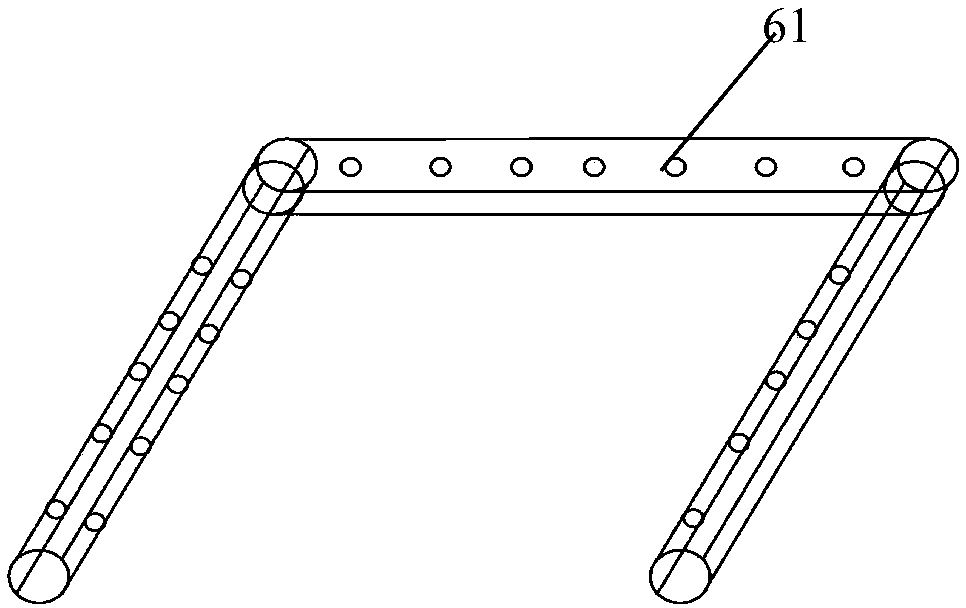

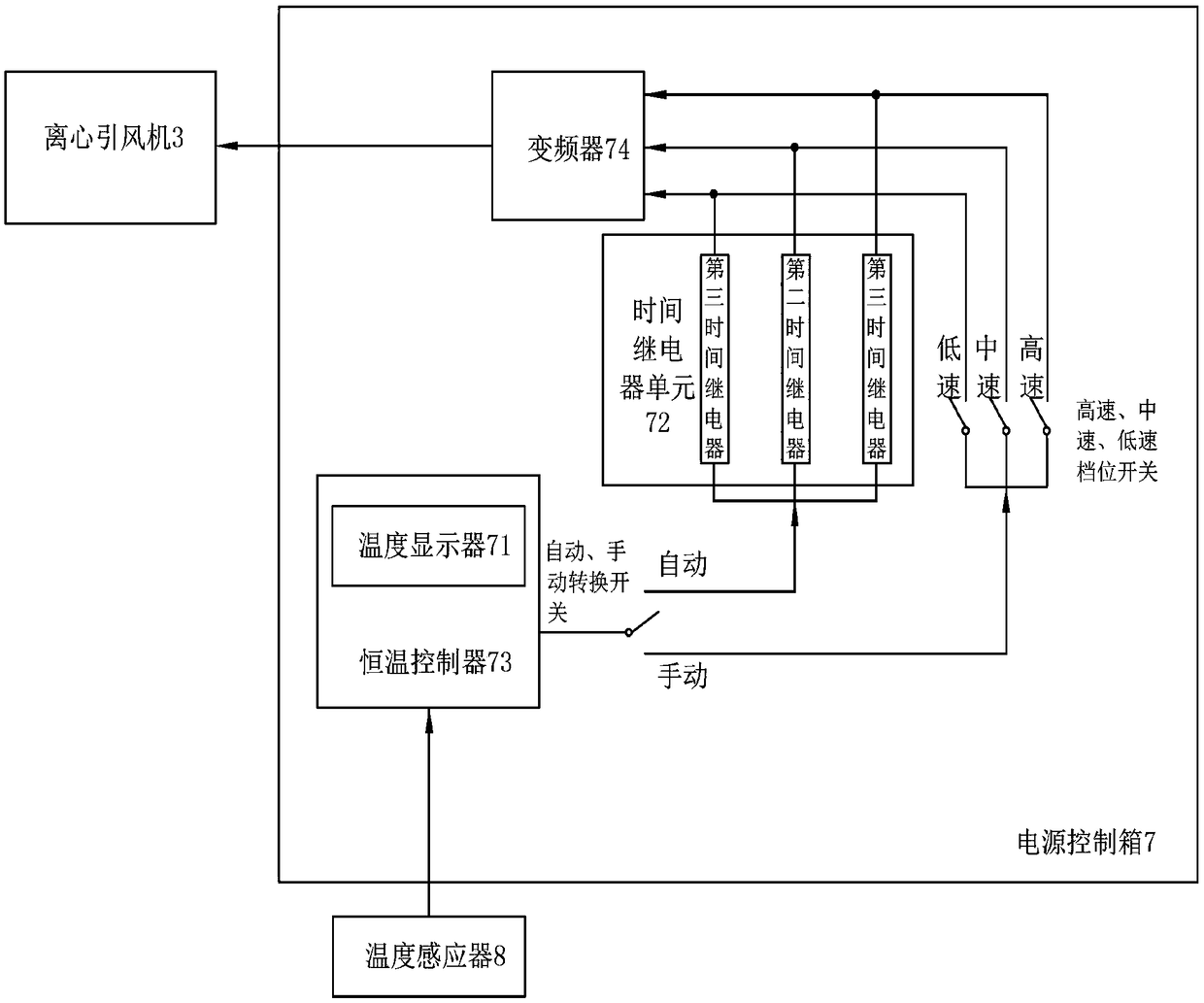

[0073]The embodiment of the invention discloses a heat preservation system for a fine aggregate silo, which includes a storage heat preservation silo, the storage heat preservation silo includes a headquarters silo 1, a branch silo 2, a centrifugal fan 3, a heat source generating device 4, and a non-porous steel pipe Heat transfer and cooling device 5, perforated steel pipe heat transfer and cooling device 6, power control box 7 and temperature sensor 8; among them, headquarters silo 1 and branch silo 2 are set adjacent to each other, and headquarters silo 1 and branch silo 2 Both include a silo wall 121, a silo ceiling 122 and an automatic rolling door 123, and the silo ceiling 122 is arranged on the top of the silo wall 121 through a steel pipe. The silo ceiling 122 is sealed and connected, the heat source generating device 4 is arranged in the headquarters silo 1, the non-porous steel pipe heat transfer and cooling device 5 is arranged on the inner side and the top of the si...

Embodiment 2

[0077] The embodiment of the invention discloses a heat preservation system for a fine aggregate silo, which includes a storage heat preservation silo, the storage heat preservation silo includes a headquarters silo 1, a branch silo 2, a centrifugal fan 3, a heat source generating device 4, and a non-porous steel pipe Heat transfer and cooling device 5, perforated steel pipe heat transfer and cooling device 6, power control box 7 and temperature sensor 8; among them, headquarters silo 1 and branch silo 2 are set adjacent to each other, and headquarters silo 1 and branch silo 2 Both include a silo wall 121, a silo ceiling 122 and an automatic rolling door 123, and the silo ceiling 122 is arranged on the top of the silo wall 121 through a steel pipe. The silo ceiling 122 is sealed and connected, the heat source generating device 4 is arranged in the headquarters silo 1, the non-porous steel pipe heat transfer and cooling device 5 is arranged on the inner side and the top of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com