A Two-Stage Buffer Positive Pile Warp Let-Off Mechanism

A technology of let-off mechanism and buffer mechanism, which is used in flannel looms, looms, textiles and papermaking, etc., can solve the problems of buffer tube life limitation, aggravating mechanism damage rate, loop evenness defects, etc., to prevent yarn Slippage, low cost of parts, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

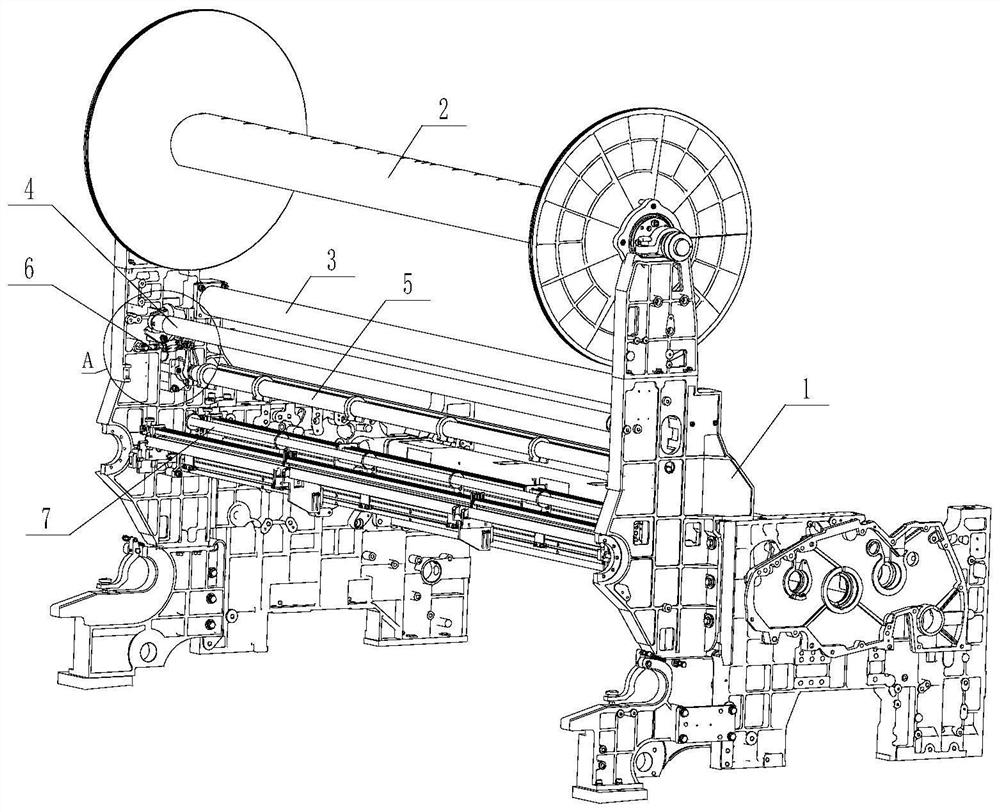

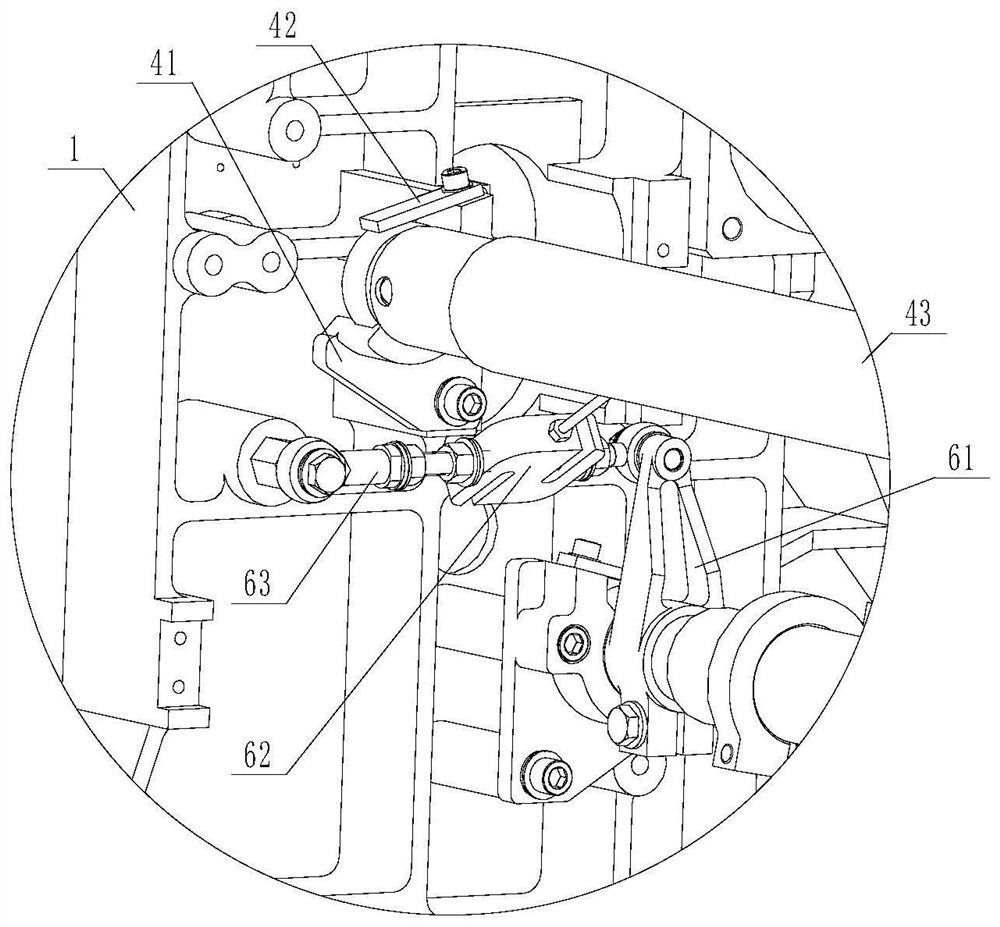

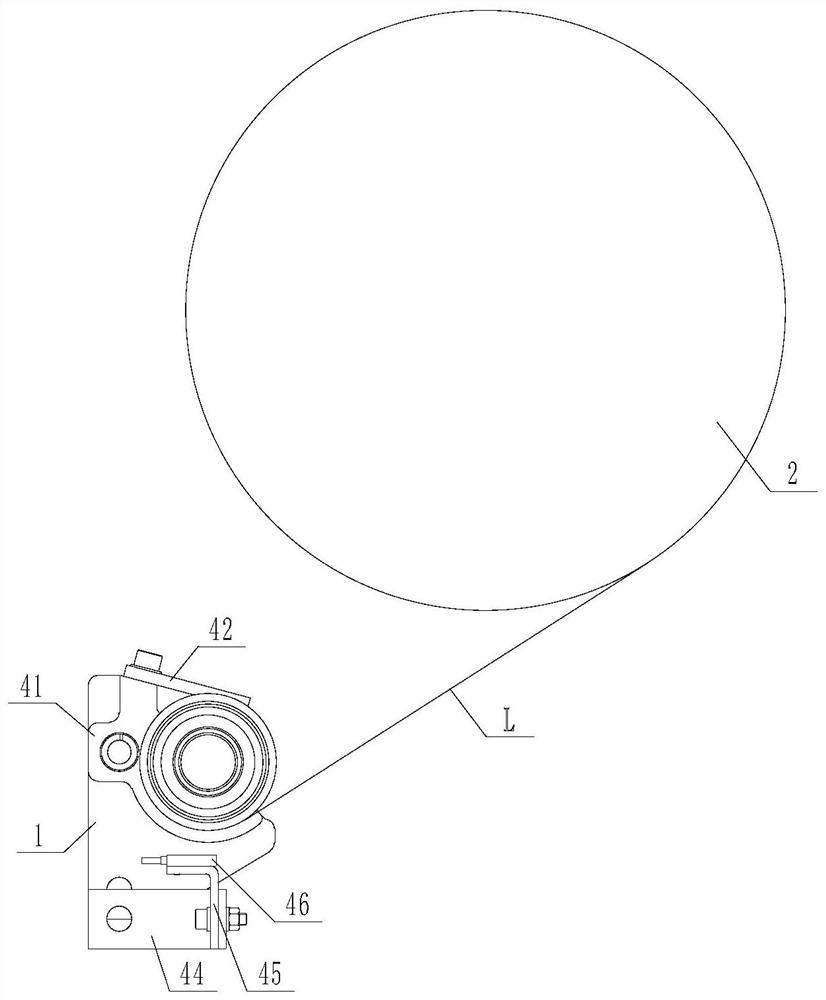

[0023] Such as Figure 1 to Figure 7 As shown, a two-stage buffering active cashmere warp let-off mechanism comprises two wallboards 1 on the left and right, a pile warp shaft 2 is arranged on the upper side of the wallboard, and an upper reinforcement mechanism 3 and an upper reinforcement mechanism 3 are installed on the wallboard. The buffer mechanism 5 and the fluff shaft counting mechanism 4, wherein the upper buffer mechanism and the fluff shaft counting mechanism are fixed on the wallboards on both sides through bearing seats to ensure the flexible rotation of the shaft; the upper reinforcement mechanism can be fixed between the two wallboards by bolts to ensure When the pile warp beam and the active let-off mechanism work, no vibration will occur.

[0024] The pile shaft counting mechanism 4 is located between the pile warp shaft 2 and the upper buffer mechanism 5 .

[0025] The hair shaft counting mechanism includes a fixing mechanism 41, a pressing mechanism 42, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com