Artificial Roman travertine and preparation method thereof

An artificial and travertine technology, which is applied in the field of artificial Roman travertine and its preparation, can solve the problems of difficult processing and typesetting, and application limitations of natural travertine, so as to improve the natural effect, control the color and pattern, and facilitate mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

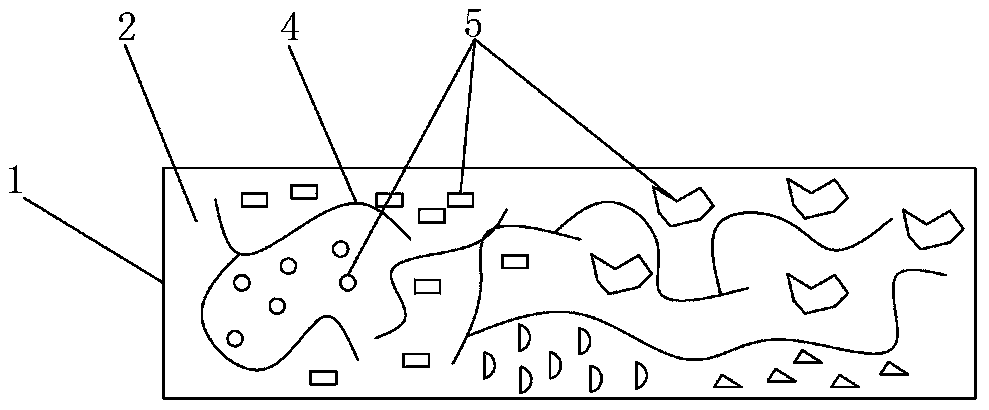

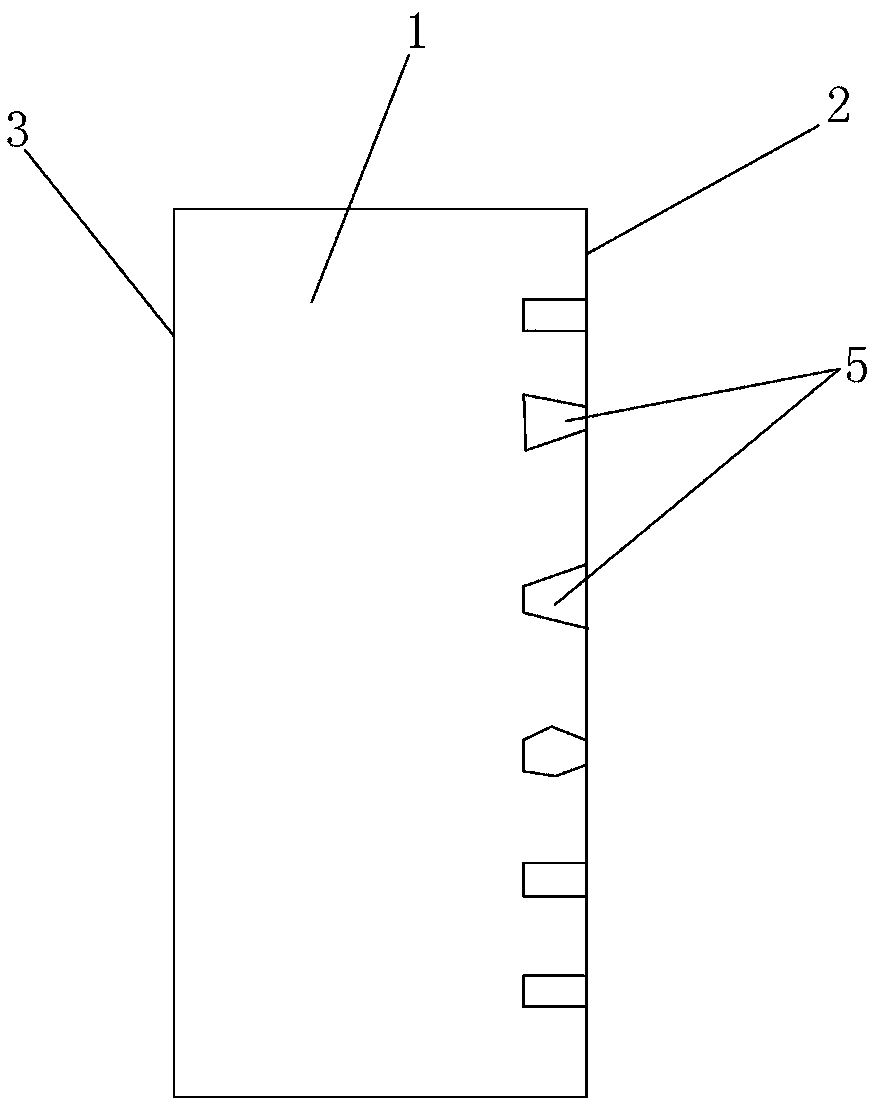

Image

Examples

Embodiment 1

[0025] A preparation method of artificial Roman travertine, the following raw materials are selected: 20 parts of cement; 70 parts of quartz sand; 2 parts of stone powder; 2 parts of silica fume; 0.2 part of early strength agent; 0.1 part of retarder; 0.2 part of latex powder; 0.1 part of water reducer; 0.1 part of defoamer; 0.2 part of fiber and iron oxide pigment, and the choice of water reducer is polycarboxylate water reducer.

[0026] First add the early strength agent, retarder, water reducer and defoamer into the high-speed disperser and mix and stir at a speed of 200 rpm for 5 minutes. Then add cement, stone powder, silica fume, latex powder, fiber and iron oxide pigment, and finally add quartz sand, and stir again at a speed of 500 rpm for 15 minutes, stirring evenly to form a mixed raw material.

[0027] Pour the mixed raw materials into the corresponding mold, operate along the grain direction of the mold when pouring the mixed raw materials, and design the pattern ...

Embodiment 2

[0031] A preparation method of artificial Roman travertine, the following raw materials are selected: 30 parts of cement; 60 parts of quartz sand; 3 parts of stone powder; 5 parts of silica fume; 0.5 part of early strength agent; 0.3 part of retarder; 0.3 part of latex powder; 0.5 part of water reducer; 0.5 part of defoamer; 0.8 part of fiber and iron oxide pigment.

[0032] First add the early strength agent, retarder, water reducer and defoamer into the high-speed disperser and mix and stir at a speed of 500 rpm for 4 minutes. Then add cement, stone powder, silica fume, latex powder, fiber and iron oxide pigment, and finally add quartz sand, and stir again at a speed of 800 rpm for 10 minutes, stirring evenly to form a mixed raw material.

[0033] Pour the mixed raw materials into the corresponding mold, operate along the grain direction of the mold when pouring the mixed raw materials, and design the pattern after filling.

[0034] The mold filled with mixed raw materials ...

Embodiment 3

[0037] A preparation method of artificial Roman travertine, the following raw materials are selected: 40 parts of cement; 50 parts of quartz sand; 4 parts of stone powder; 8 parts of silica fume; 0.8 part of early strength agent; 0.4 part of retarder; 0.4 part of latex powder; 0.8 parts of water reducing agent; 0.4 parts of defoamer; 1.5 parts of fiber and iron oxide pigment.

[0038] First add the early strength agent, retarder, water reducer and defoamer into the high-speed disperser and mix and stir at a speed of 800 rpm for 2 minutes. Then add cement, stone powder, silica fume, latex powder, fiber and iron oxide pigment, and finally add quartz sand, and stir again at a speed of 1500 rpm for 10 minutes, stirring evenly to form a mixed raw material.

[0039] Pour the mixed raw materials into the corresponding mold, operate along the grain direction of the mold when pouring the mixed raw materials, and design the pattern after filling.

[0040] Send the mold filled with mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com