Efficient automatic cable reel loading and pay-off device

A reel and optical cable technology, applied in the field of high-efficiency optical cable reel self-loading device, can solve the problems of waste of manpower, low efficiency, high cost, etc., and achieve the effect of fast disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

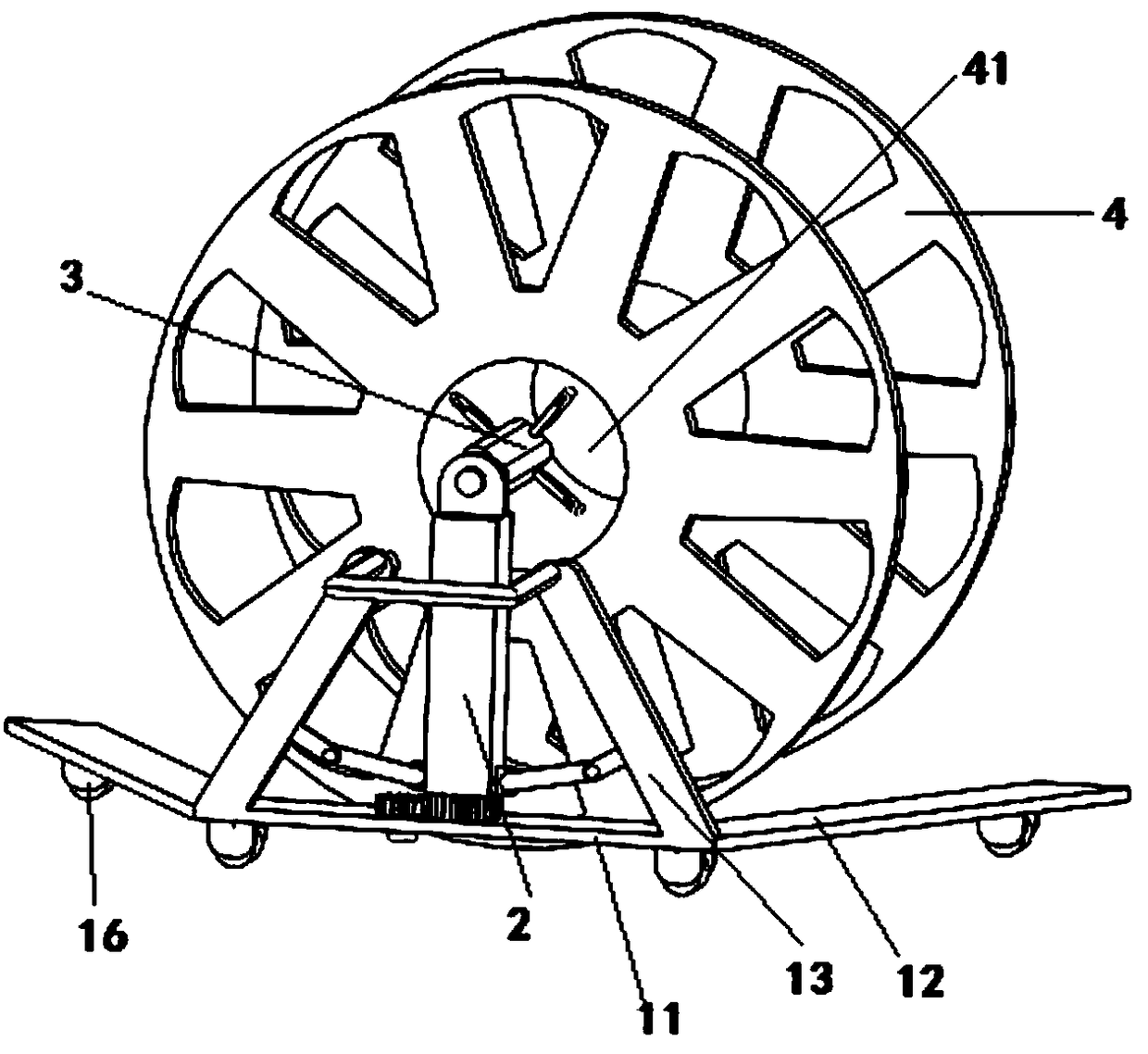

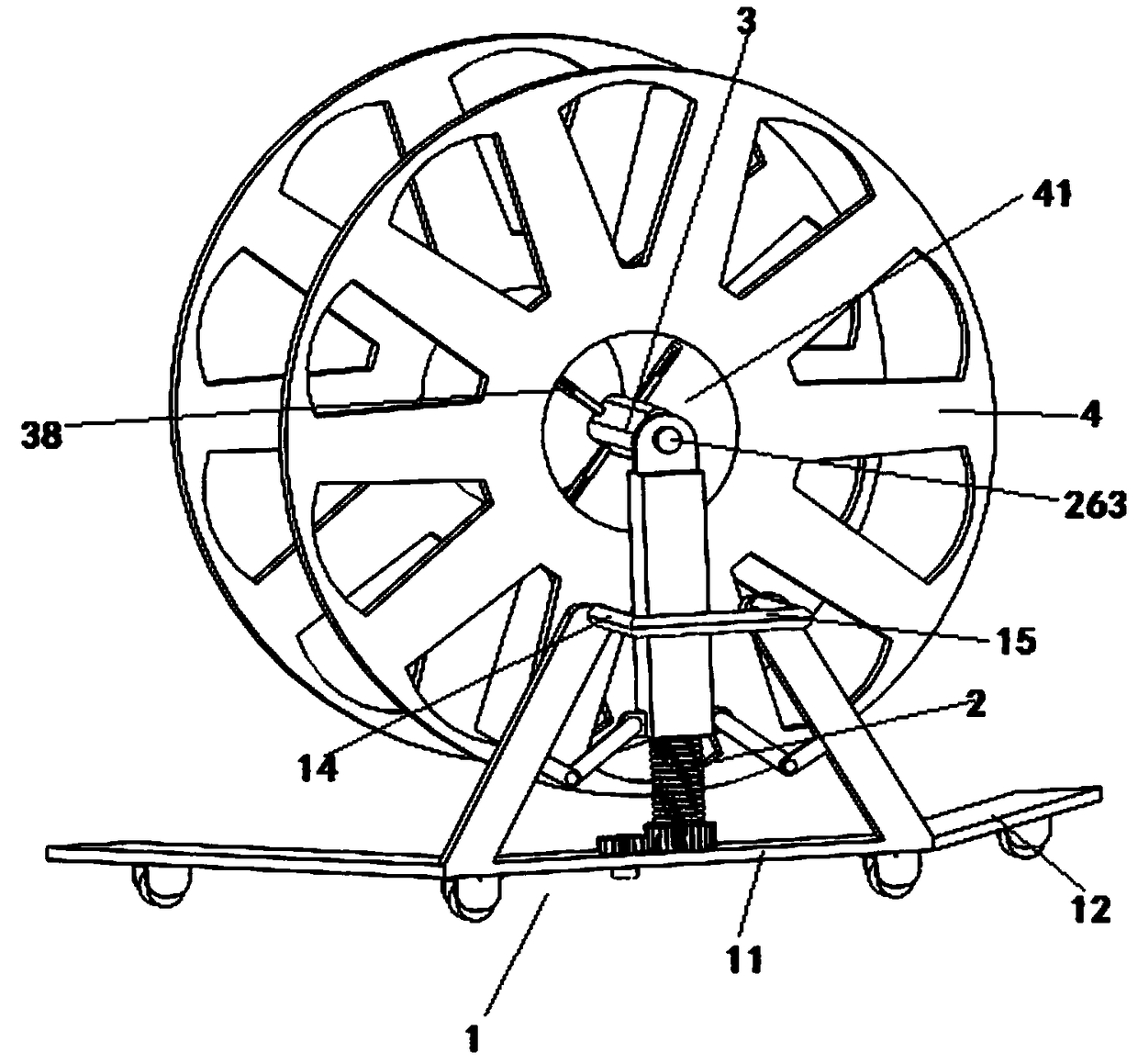

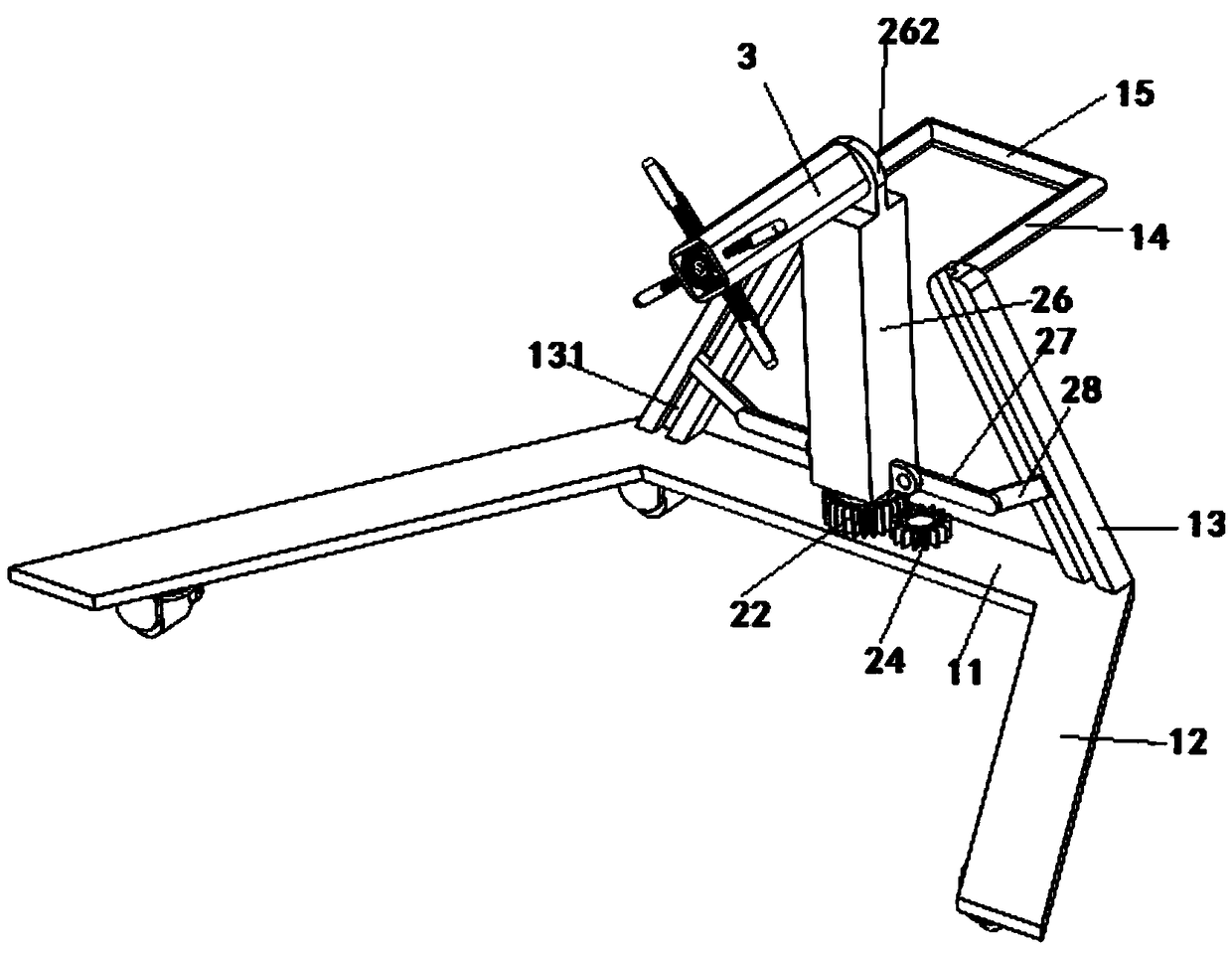

[0025] A high-efficiency optical cable reel pay-off device from the upper reel, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the support frame 1 is provided with a height adjustment mechanism 2 on the support 1, and the top of the height adjustment mechanism 2 is provided with a reel rotation mechanism 3;

[0026] The support frame 1 includes a fixed support bar 11, the two ends of the fixed support bar 11 are integrally connected and fixed with two support bars 12, and the angle between the left side wall of the two support bars 12 and the side wall of the fixed support bar 11 is 60- 70 degrees; the two ends of the bottom surface of the fixed support bar 11 and the bottom surfaces of the front ends of the two support bars 12 are equipped with universal rollers 16; The angle between the right side wall of the position-limiting pole 13 and the surface of the fixed pole 11 is 50-60 degrees, so the tops of the two space-limiting poles 13 are clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com