Method and system for predicting residual lives of tools in online manner

A prediction method and tool technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of staying, unable to be applied, and no tool remaining life online prediction research and application, etc., to improve the prediction accuracy Effect

Active Publication Date: 2018-11-30

SHANGHAI JIAO TONG UNIV

View PDF4 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (1) The model in this article is suitable for long-term sequences, and the length of the time series (the number of tool passes) in this article reaches more than 300, which is not suitable for processing types with shorter processing time sequences;

[0005] (2) The tool damage experiment was carried out in this paper, but in the high-value workpiece processing site, in order to ensure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

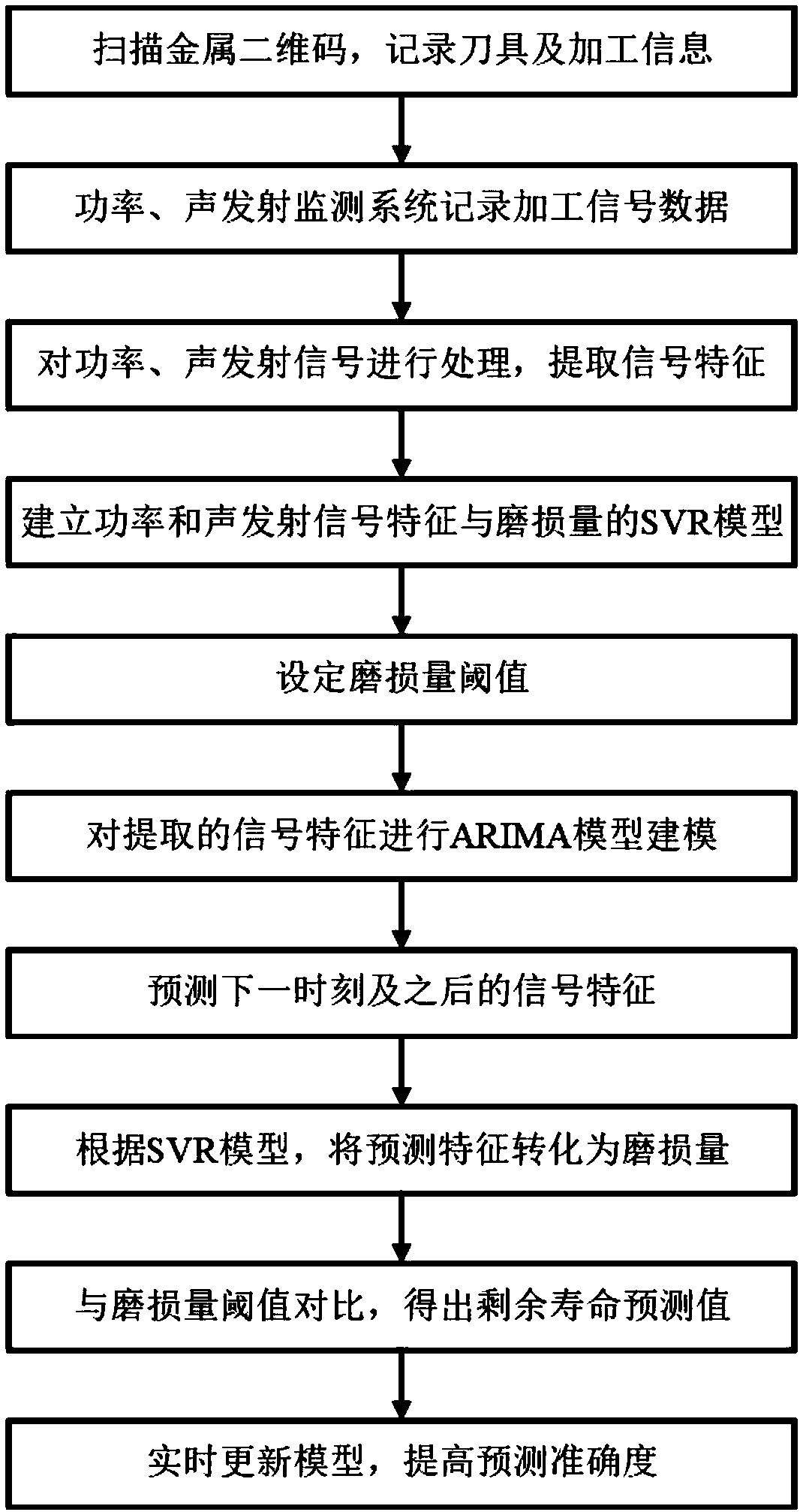

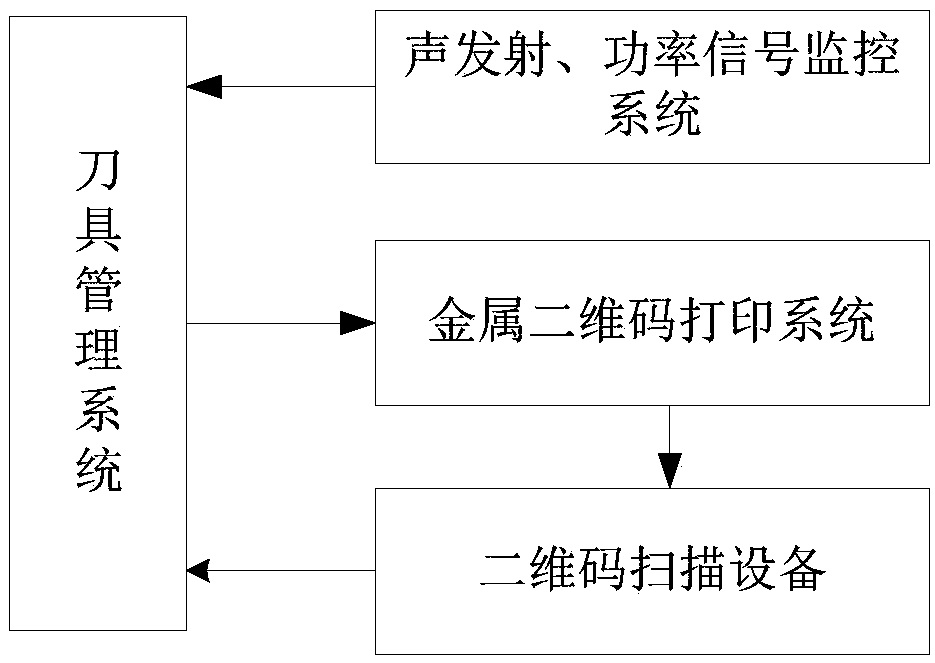

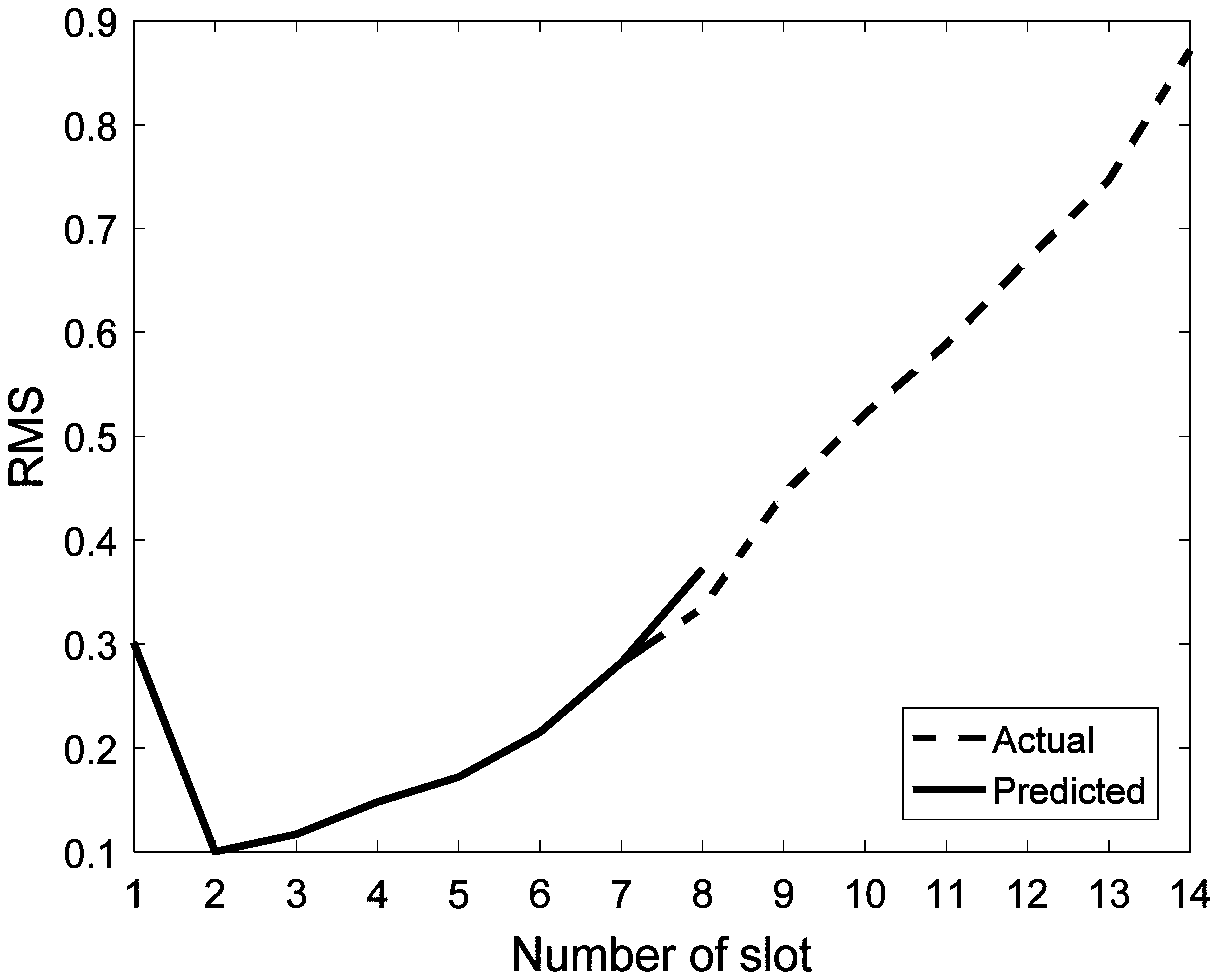

The invention provides a method and a system for predicting the residual lives of tools in an online manner. The method includes inputting tool and machining information into a tool management systemand acquiring acoustic emission and power signals in real time; building SVR (support vector regression) models for the same types of tools in tool databases, establishing relations between signal characteristics and abrasion loss and setting thresholds. The acoustic emission and power signals of each machining time point are processed during machining, a series of characteristics are extracted, autoregressive integral moving average models are built, predicted values of the signal characteristics can be obtained and then are converted into the abrasion loss by the aid of the SVR models, the abrasion loss is compared to the thresholds, and accordingly the residual lives of the tools at current moments can be computed. The system comprises the tool management system, an acoustic emission and power signal monitoring system, a metal two-dimensional code printing system and two-dimensional code scanning equipment. The method and the system have the advantages that tool residual life prediction accuracy and real-time performance can be improved, the tool utilization rate can be increased, and the production cost can be reduced.

Description

technical field [0001] The invention relates to the field of machining tools, in particular to a method and system for online prediction of tool remaining life. Background technique [0002] With the introduction of the concept of "intelligent manufacturing" and the rapid development of digital and information-based manufacturing technologies, the use of various digital machine tools has become more common. As a part of the entire processing system that directly contacts the workpiece, the tool's processing life determines the entire manufacturing process. Therefore, the monitoring of the processing status and the prediction of the processing life are becoming more and more important. With the help of the tool management system, the tool can be monitored throughout its life cycle, which plays an important role in the effective use and rational allocation of the tool, and can further improve the processing quality and production efficiency, and reduce production costs. Throu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23Q17/09

CPCB23Q17/0957B23Q17/0995

Inventor 胡小锋蔡伟立刘颖超

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com