Precision pneumatic clamp for machining

A pneumatic fixture and machining technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unstable product size, low clamping efficiency, uneven clamping force, etc., to achieve clamping High efficiency, stable product size, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

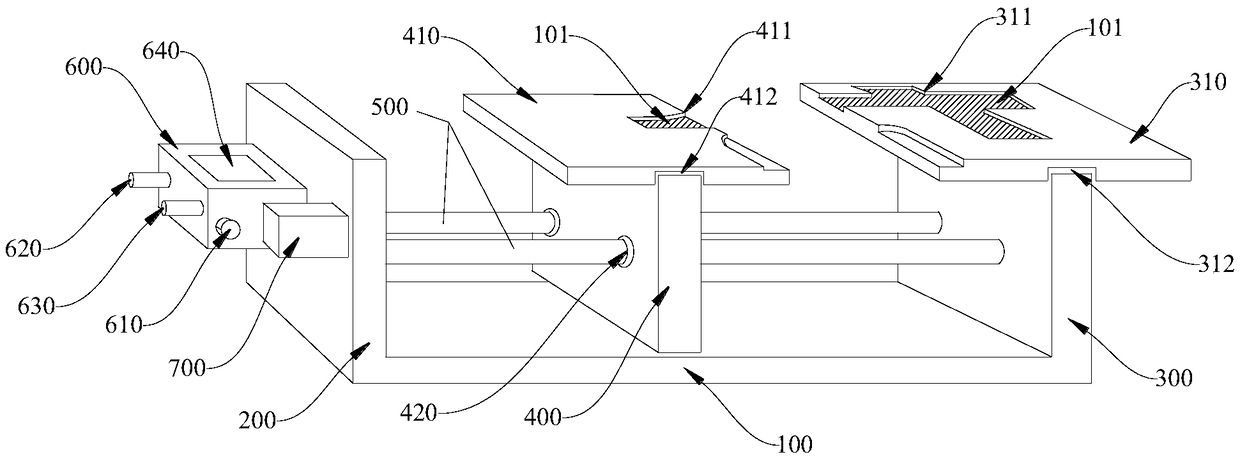

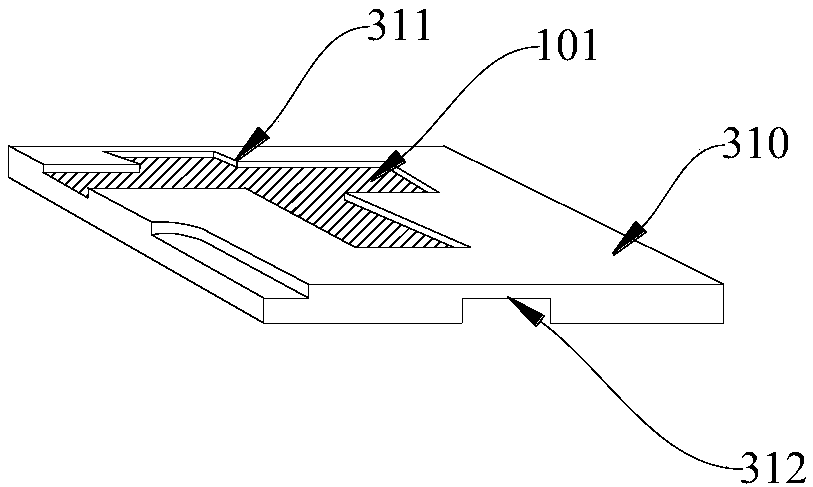

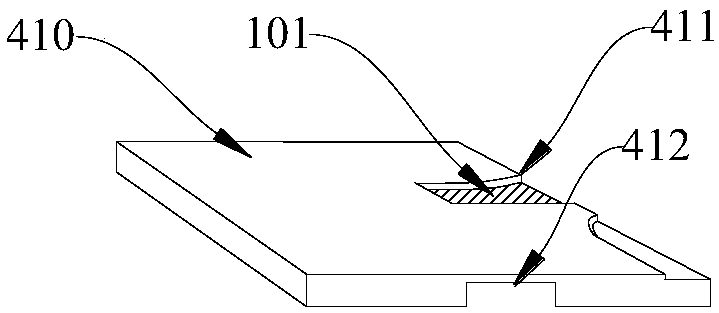

[0027] see Figure 1-Figure 5 , in an embodiment of the present invention, a precision pneumatic fixture for machining, including a base 100, a first fixed side plate 200, a second fixed side plate 300, a sliding plate 400, a fixed clamp block 310, and a sliding cover plate 410 , 2 guide rails 500, a cylinder 600, a manual valve 610 and an air flow regulating valve 700, the first fixed side plate 200 and the second fixed side plate 300 are installed on the left and right ends of the base 100 respectively, the cylinder 600 and The air flow regulating valve 700 is installed on the outer side wall of the first fixed side plate 200, the fixed splint 310 is installed on the upper end of the second fixed side plate 300, and one end of the two guide rails 500 is inserted through the first A fixed side plate 200 is connected to the cylinder 600, and the other end is inserted through the second fixed side plate 300, and the sliding plate 400 is installed on the two guide rails 500 betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com