High-speed and low-noise wire twisting-off machine

A twist-breaking machine and steel wire technology, applied in the field of metal wire processing, can solve the problems of low efficiency, high noise, uncontrollable wire cutting length and quality, etc., and achieve the effect of reducing production noise, reasonable structure design, and ensuring twist-breaking quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

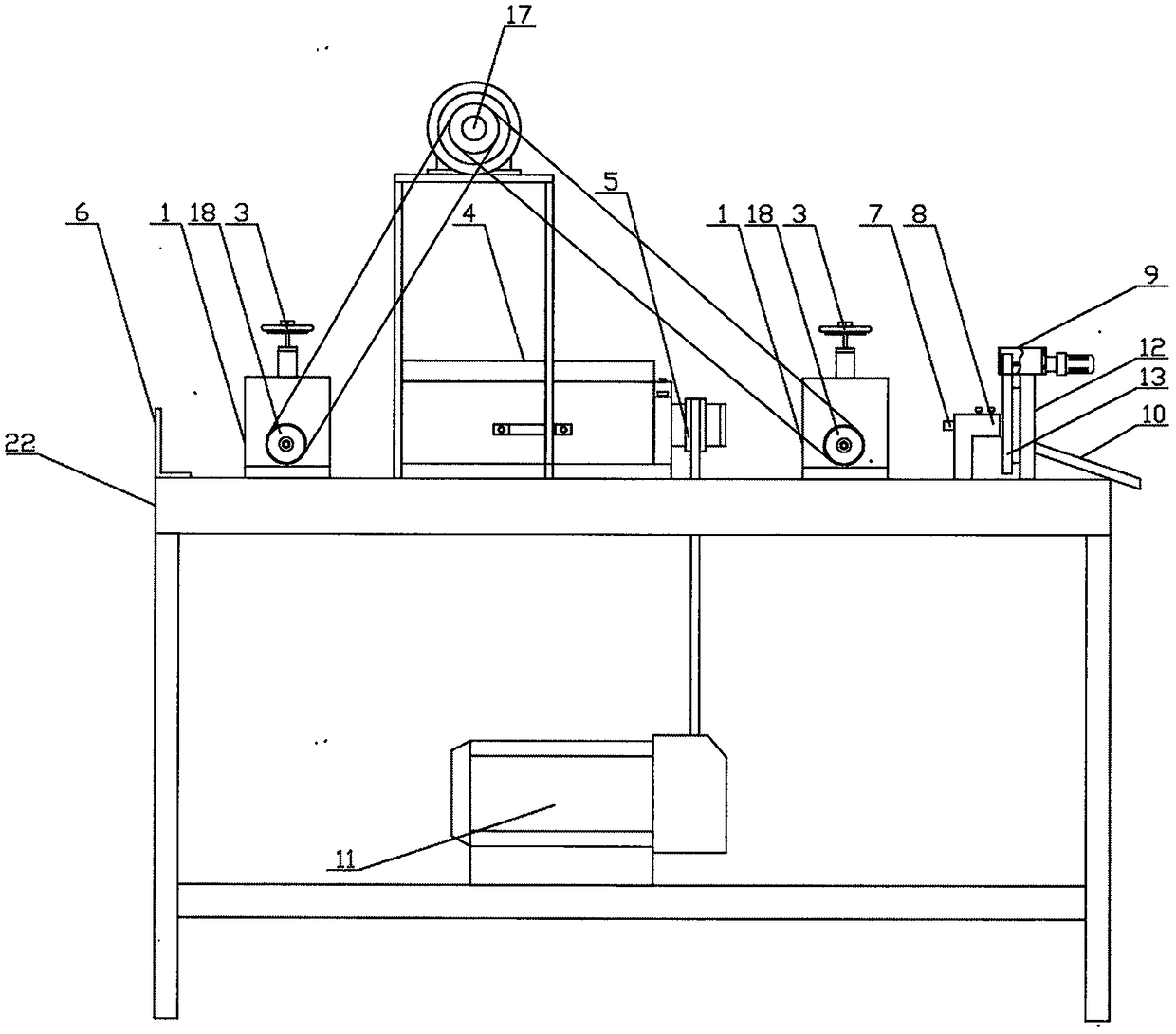

[0024] According to attached figure 1 , 2 , 3: the present embodiment provides a high-speed and low-noise wire twisting machine, including an operating platform 22, a fixed knife assembly, a moving knife assembly, a straightener assembly 4 and two groups of traction boxes 1;

[0025] The fixed knife assembly, the moving knife assembly, the straightener assembly 4 and the traction box 1 are linearly distributed on the operating platform 22 with the metal wire as the center, and the straightener assembly 4 is located on the fixed knife The front side of the assembly, the input side and the output side of the straightener assembly 4 are respectively provided with a traction box 1, and the moving knife assembly is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com