Double-precision optical regulation transmission device

A transmission device and optical adjustment technology, applied in optics, optical components, instruments, etc., can solve the problems of interference efficiency adjustment, harmful effects of beam alignment adjustment, and low adjustment efficiency, so as to improve adjustment stability and increase adjustment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

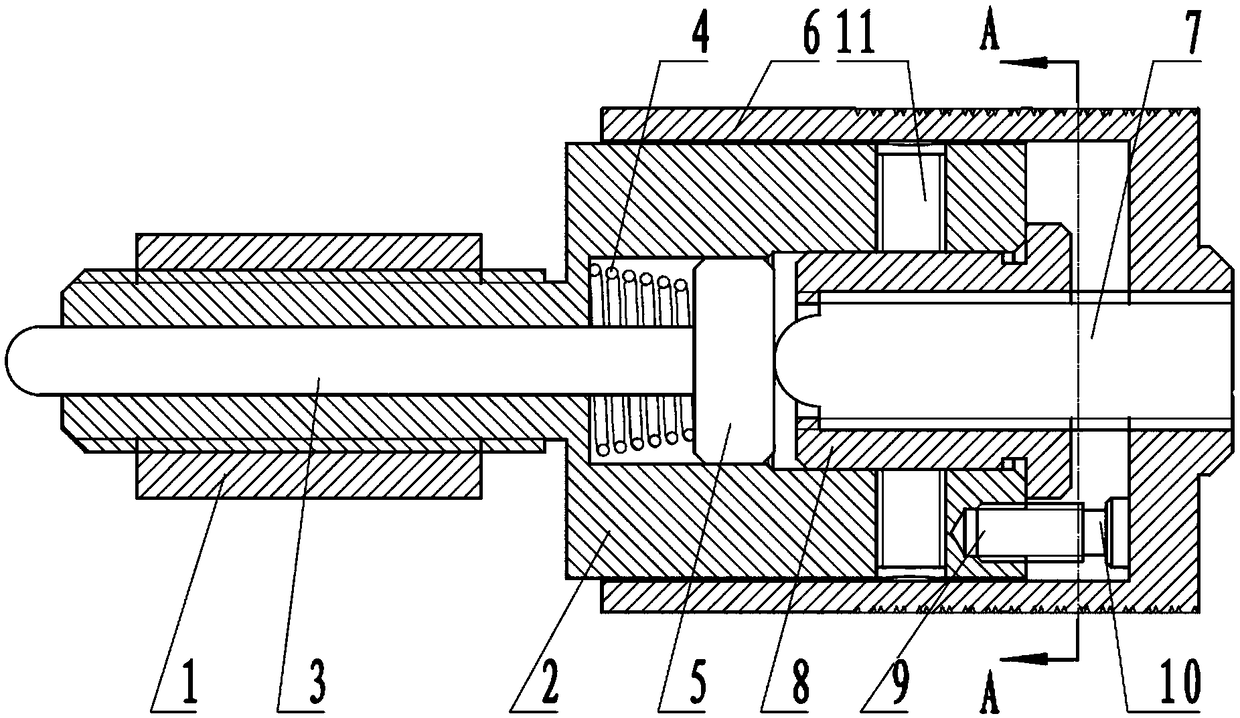

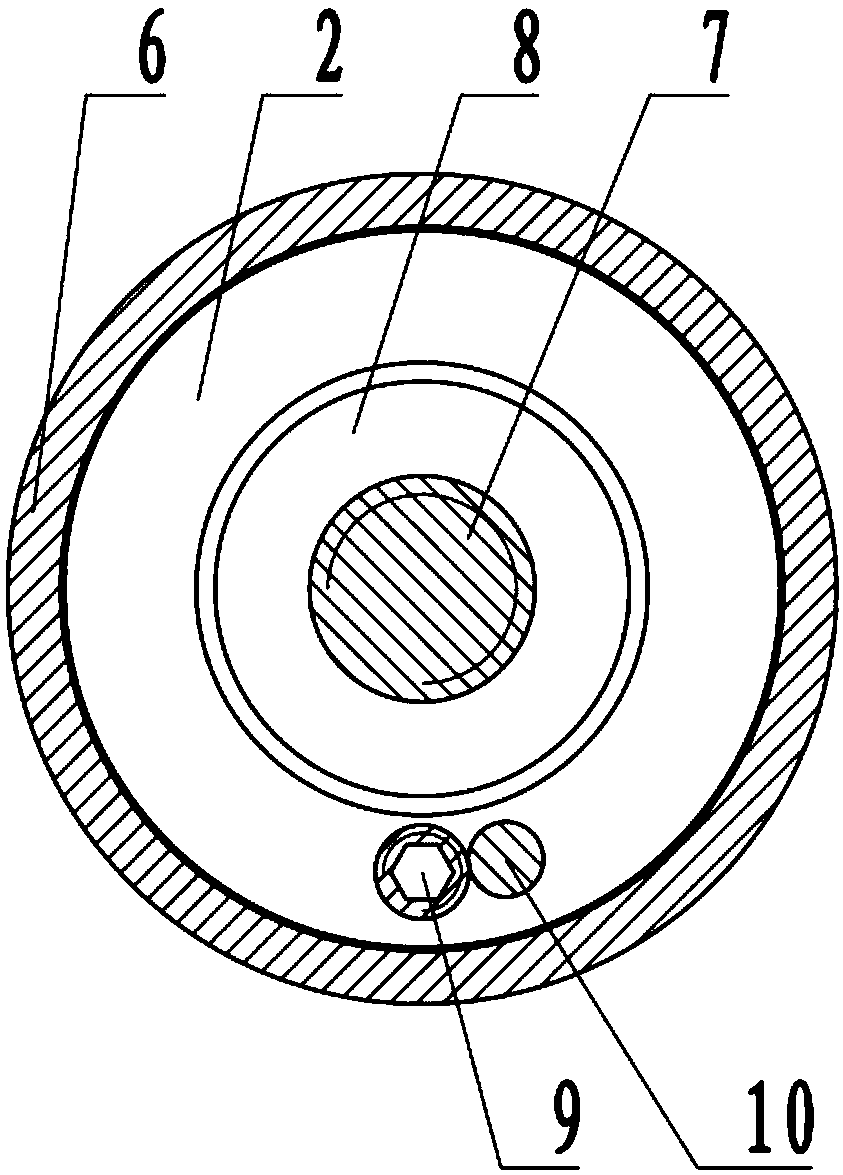

[0020] see figure 2 And and 3, the double-precision optical adjustment transmission device of the present invention includes a coarse-threaded nut 1 fixed on the optical adjustment frame and a coarse-threaded screw 2 threadedly connected with the coarse-threaded nut 1 .

[0021] The described coarse tooth screw 2 is provided with a center hole along its axial direction, and a ball head polished rod 3 that is a ball head is installed in the center hole in a moving fit. The other end of the head expands into a chamber, and the chamber is provided with a compression spring 4, a slider 5 and a fine thread nut 8 in sequence along the ball head direction away from the polished rod 3 of the ball head; wherein, the compression spring 4 wears Located outside the polished ball rod 3, the slider 8 is connected to the polished rod 3, and the fine thread nut 8 and the coarse thread screw 2 are in contact with each other, and two anti-slip screws 11 are provided to prevent slippage. Screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com