Self-adjusting line hanging device for hard soil construction

A self-adjusting, hard soil technology, applied in roads, buildings, road repairs, etc., can solve problems such as unqualified construction quality, unfinished construction, and hanging wire piles driven into the road bed, so as to improve the efficiency and accuracy of wire hanging , reduce labor and time input, and avoid the effects of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

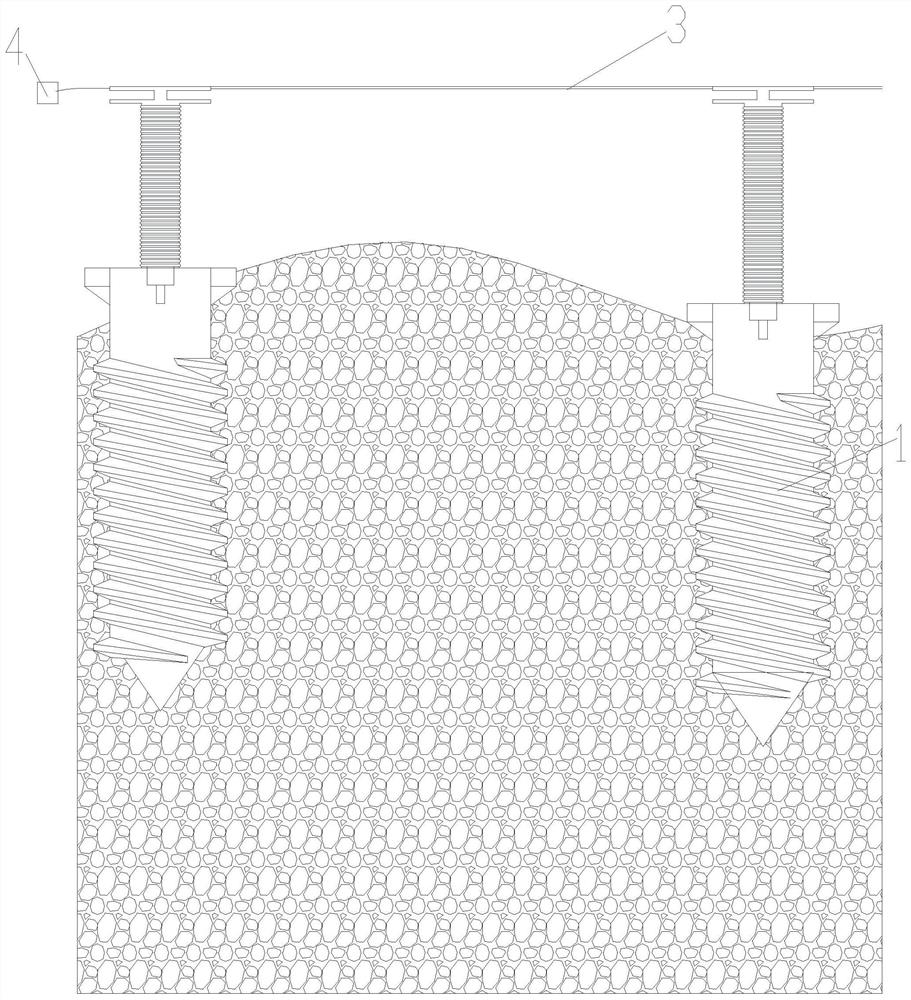

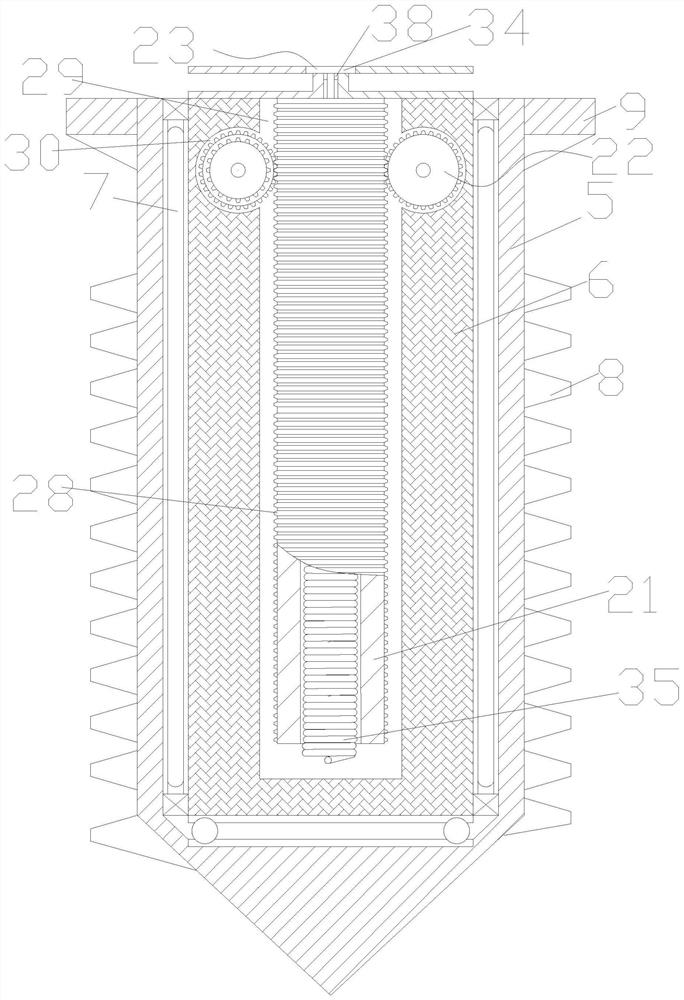

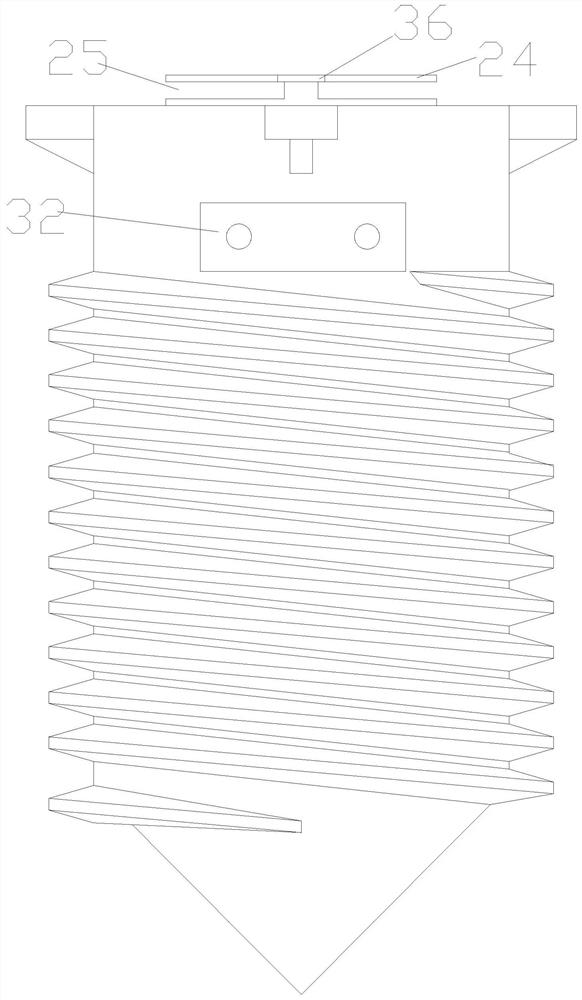

[0026] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a cross-sectional view of the screw-in type hanging wire pile of the present invention, image 3 It is the front view of the screw-in type hanging stake of the present invention, Figure 4 It is the rear view of the screw-in type hanging stake of the present invention, Figure 5 It is a structural schematic diagram of the mounting device of the present invention, Figure 6 It is a top view of the mounting device of the present invention, Figure 7 It is a sectional view of C-C of the mounting device of the present invention, Figure 8 It is a partial enlarged view of A place of the mounting device of the present invention, Figure 9It is a top sectional view of the screw-in type hanging pile of the present invention, as shown in the figure: a self-adjusting wire hanging device suitable for hard soil construction in this embodiment includes a screw-in type hanging pile 1 that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com