A numerical control machining method for I-shaped profiles

A processing method and technology of I-shaped profiles, which are applied in the field of profile processing, can solve problems such as insufficient processing rigidity, easy chattering during processing, and poor processing rigidity of supporting columns, so as to reduce straightness, clamping and alignment time, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

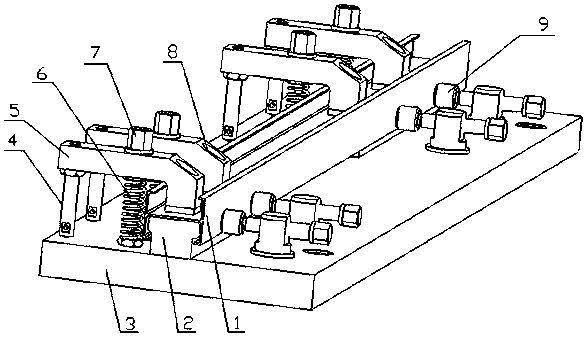

[0050] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0051] A kind of I-shape profile numerical control processing method, concrete steps are as follows:

[0052] 1) Prepare and process reference holes

[0053] Firstly, drill a hole on the I-shaped profile 1, then ream the hole, and ream the hole after reaming to achieve H-level precision, and process the reference hole, and the perpendicularity between the processed reference hole and the web surface of the I-shaped profile is ≤ 0.05;

[0054] 2) Position and clamp the I-shaped profile

[0055] Fix the positioning and clamping fixture on the machine tool, and straighten the tooling, position and clamp the I-shaped profile 1 through the positioning and clamping fixture, and at the same time correct the non-clamping side to ensure that the straig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com