A coiled wire material storage device for welding

A wire and roll technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unfavorable storage and use, easy misalignment and separation of wire materials, easy tilting and overturning, etc., to achieve structural Compact, simple and convenient collection, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

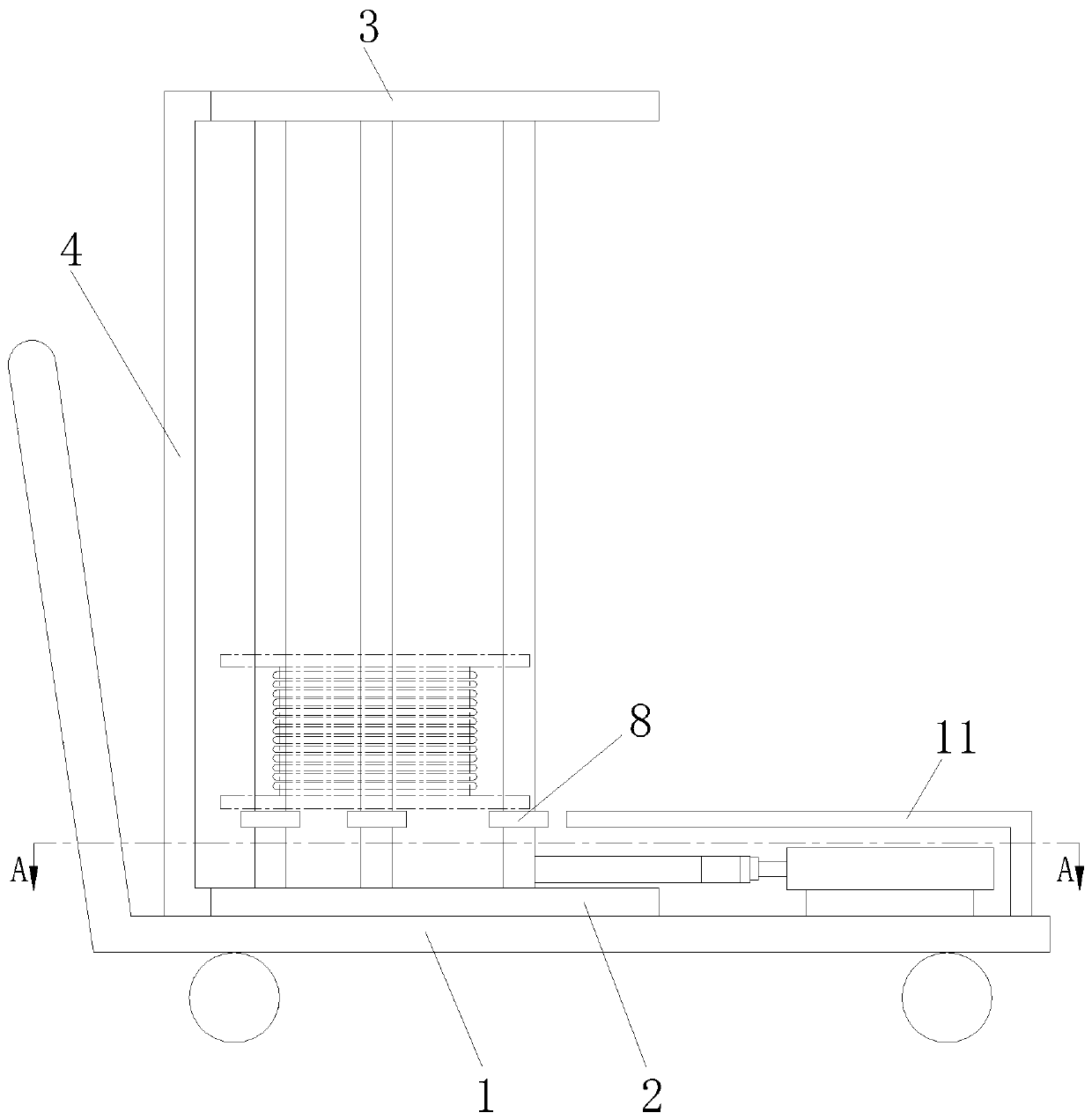

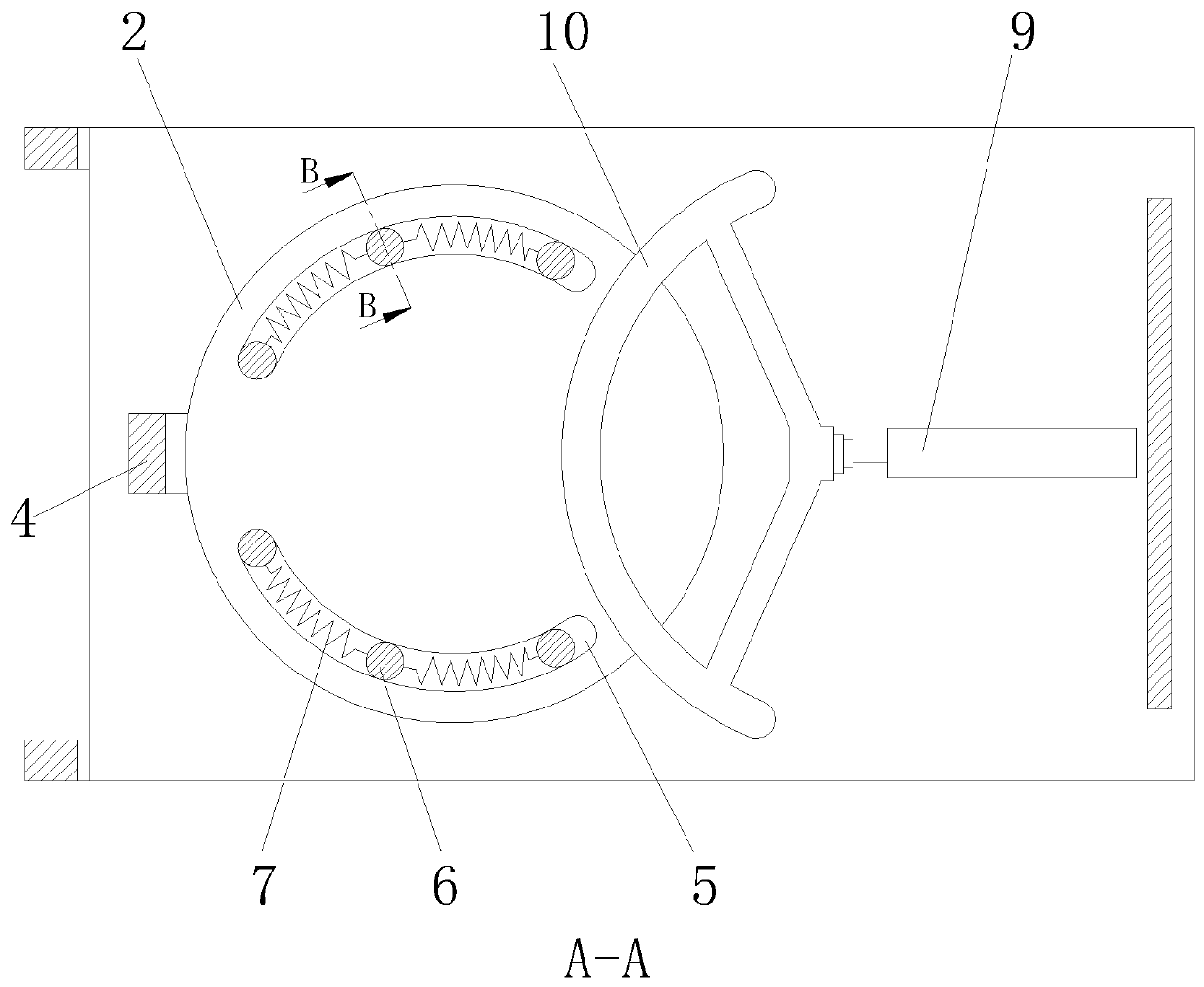

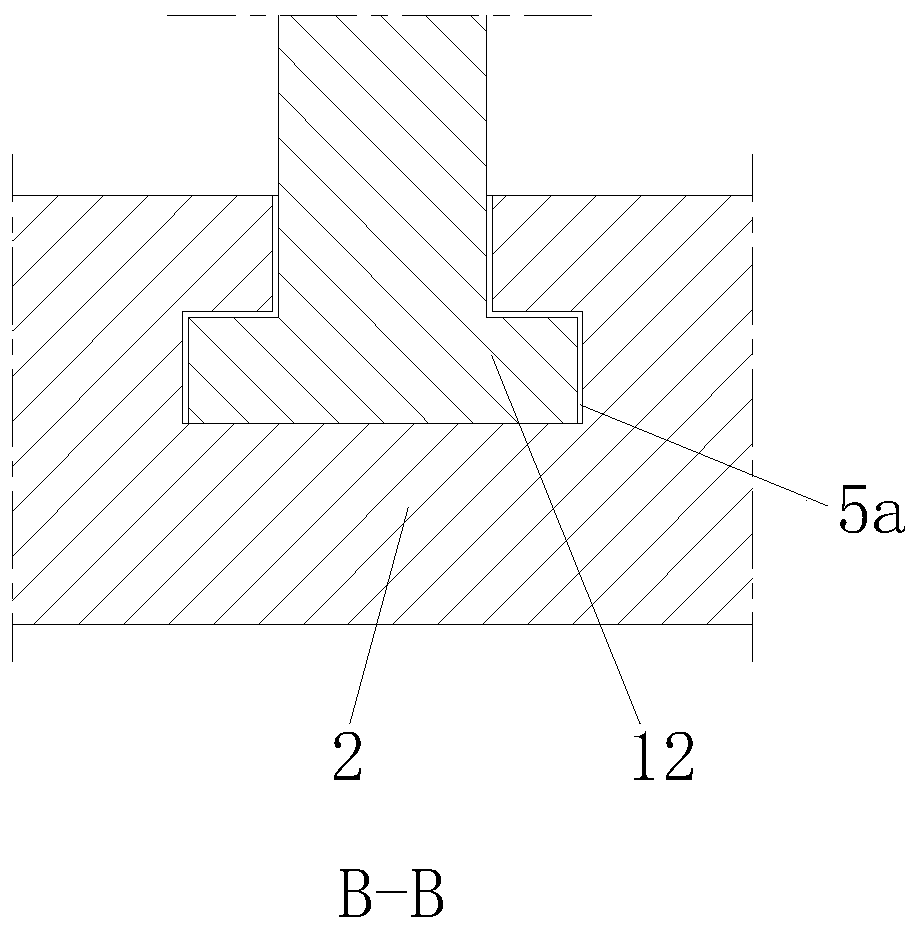

[0017] Such as Figure 1 to Figure 4 As shown, a coiled wire material storage device for welding includes a flat trolley 1, and the flat trolley 1 is provided with a lower disc 2 and an upper disc 3 distributed in parallel, and the lower disc 2 The left side of the left side is fixed with the connecting column 4 that links to each other with the upper disk 3, and the diameter of described lower disk 2 and upper disk 3 is equal and is provided with the arc-shaped chute 5 that is concentric with itself, and described arc-shaped chute 5 are two and distributed symmetrically front and back, three columns 6 are slidably connected to the corresponding arc-shaped chute 5 in the lower disk 2 and the upper disk 3, and the adjacent columns 6 are supported by a The spring 7 in the arc-shaped chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com