Full lamination device and method suitable for large size touch screen (G+G)

A touch screen, large-size technology, applied in the field of display screens, can solve the problems of unguaranteed lamination accuracy, low production efficiency, and low yield rate, and achieve the effect of simple and fast dispensing process, reduced line crossing, and strong variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

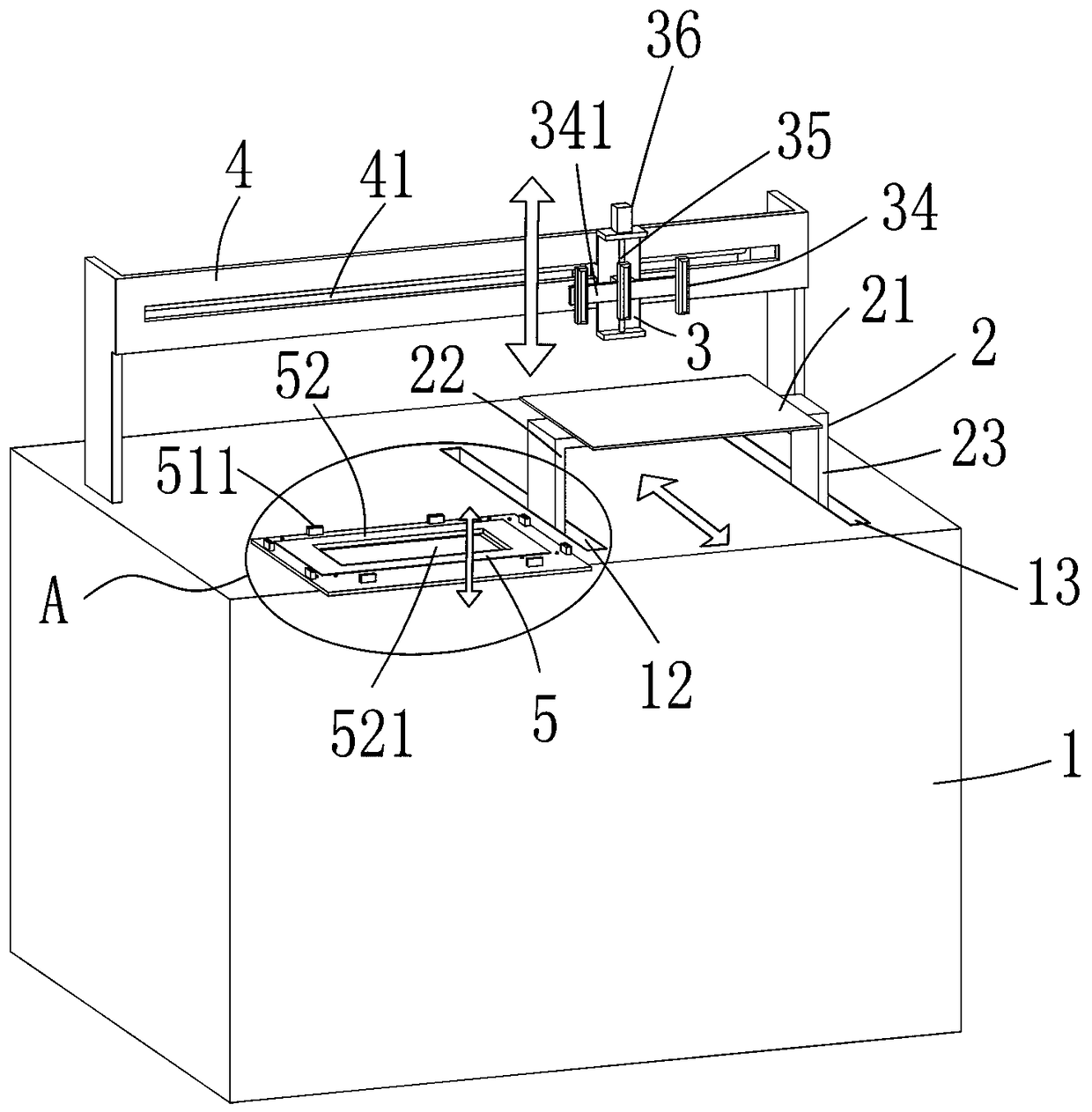

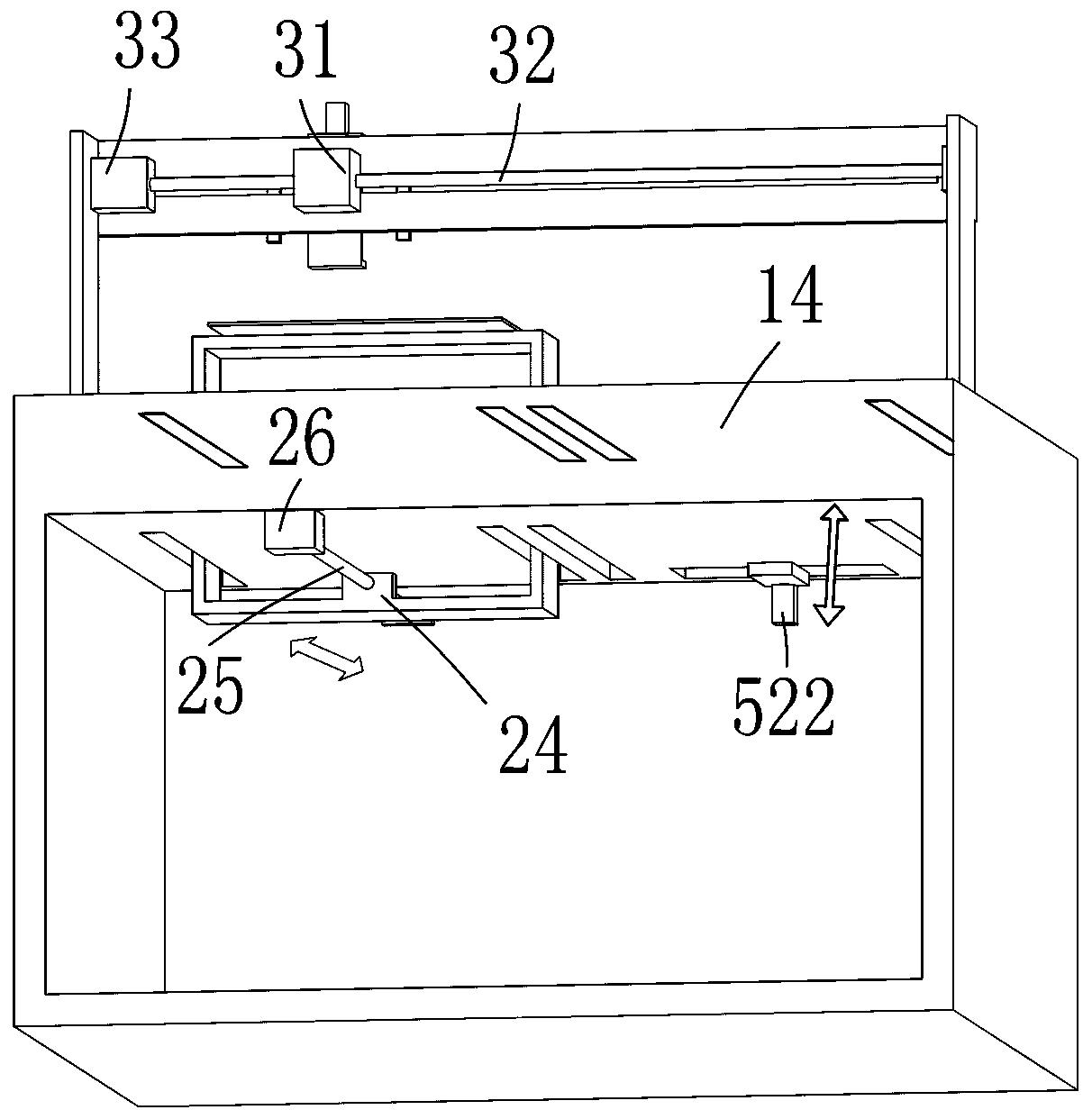

[0035] Such as figure 2 , image 3 As shown, a fully laminating device suitable for large-size touch screen (G+G), on which there is a dispensing module and a machine frame 1, wherein the dispensing module is composed of a limit support mechanism 2, a dispensing device 3 1. The displacement device 4 is composed of the displacement device 4, which is horizontally arranged on the upper end of the machine frame 1, on which a long strip-shaped groove 41 is horizontally arranged, and the glue dispensing device 3 is arranged on the groove 41 and can move along the groove 41. Sliding horizontally, there is a screw module 31 and three dispensing needles 34 on the dispensing device 3, and a horizontal screw 32 is pierced on the screw module 31, and the horizontal screw 32 and the elongated slot of the displacement device 4 41 are arranged in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com