Comprehensive low-voltage ride-through method for doubly-fed wind turbines based on stator series dynamic reactance

A low-voltage ride-through and doubly-fed fan technology, applied in wind power generation, electrical components, circuit devices, etc., can solve the problem of reducing the current injection capacity of the rotor-side converter, making it difficult to effectively solve the overvoltage of the DC bus, and threatening the safety of DFIG operation, etc. problem, to achieve the effect of safe recovery, improve reactive current injection capability, and reduce the peak value of rotor current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

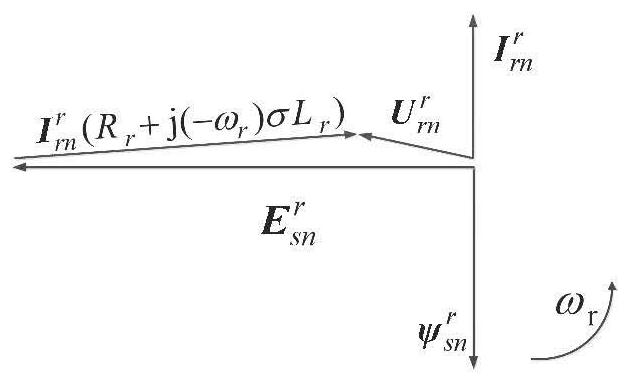

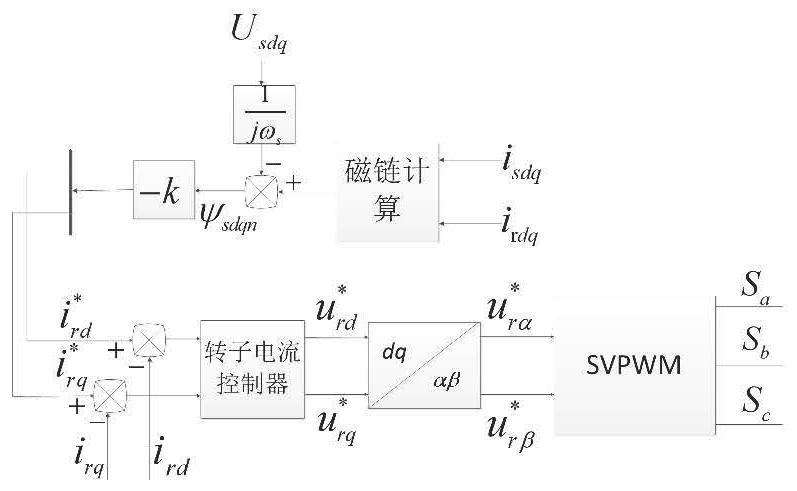

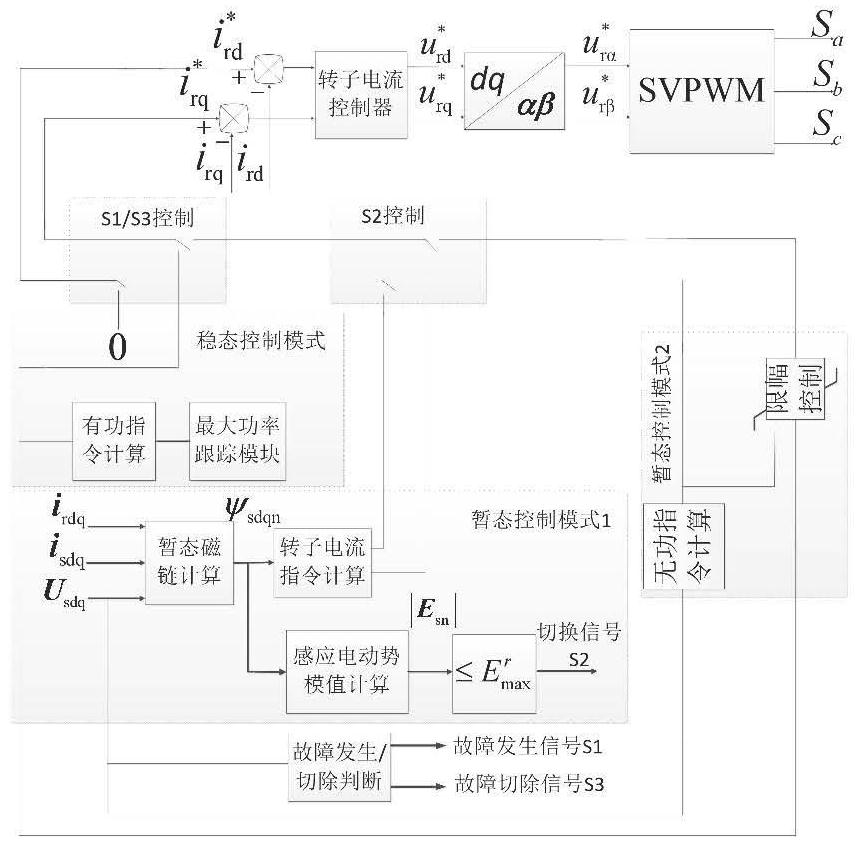

[0056] The comprehensive low-voltage ride-through method based on stator series dynamic reactance proposed by the present invention provides a stator series reactance value setting method and a method for determining a reasonable switching time of reactance based on transient induced electromotive force modulus observation through theoretical analysis. The RSC control strategy matched with the hardware was designed, and on this basis, a low-voltage ride-through scheme for switching between large and small reactance dual modes was formulated: after a fault occurs, DFIG switches from steady-state control mode to high-reactance transient control Mode (that is, the combination of stator reactance with large resistance value and transient flux linkage active attenuation control strategy) ensures that the rotor overcurrent is effectively suppressed and at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com