Detecting clamp for circle run-out of specific shaft-type component

A technology for shaft parts and testing fixtures, applied in measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of shortening the service life of the machine, low measuring accuracy, affecting the matching accuracy, etc., to reduce labor costs, high efficiency, The effect of easy error control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

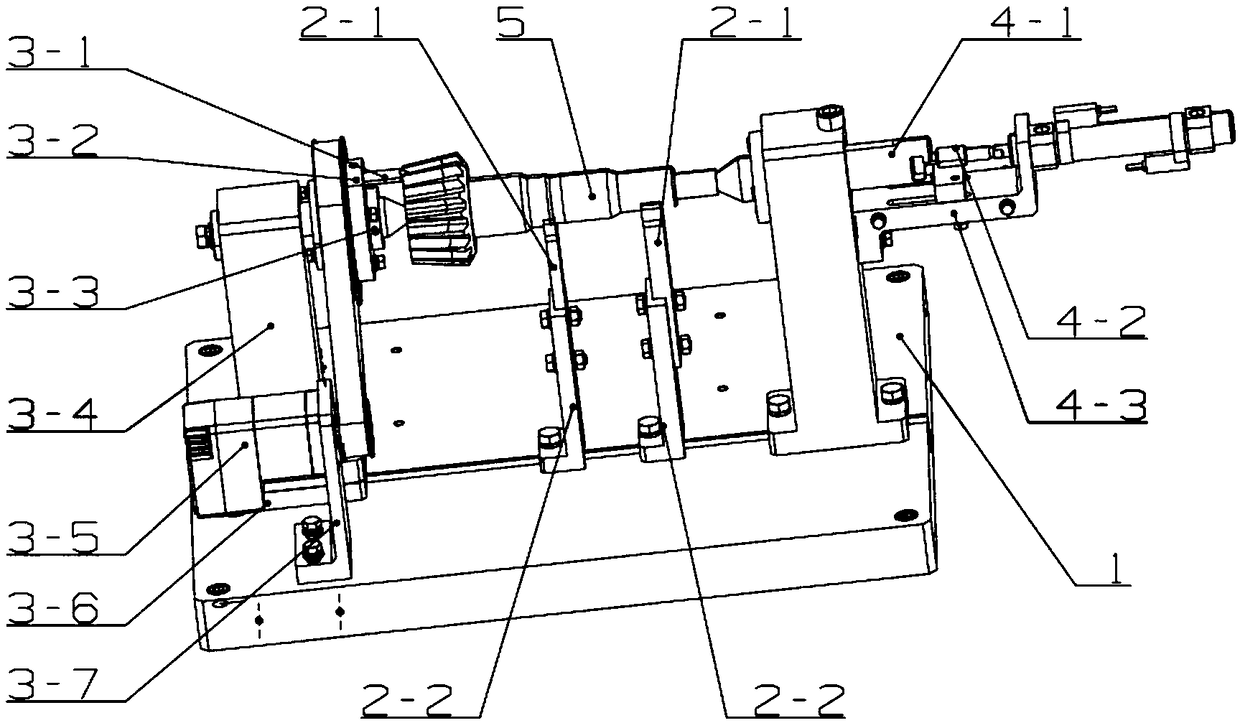

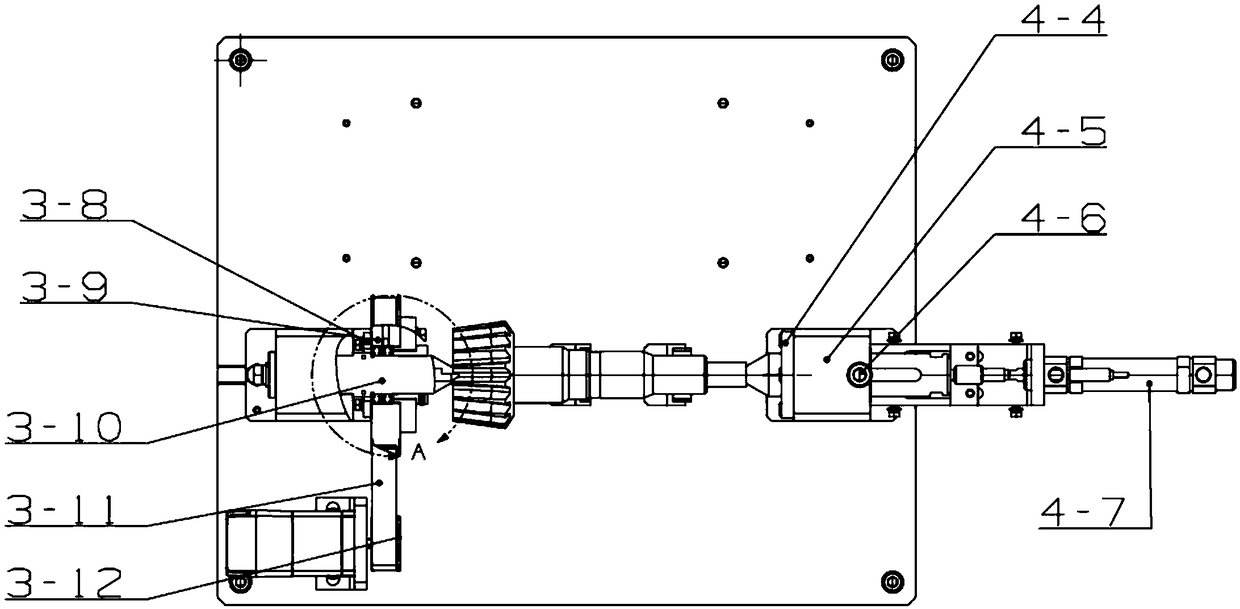

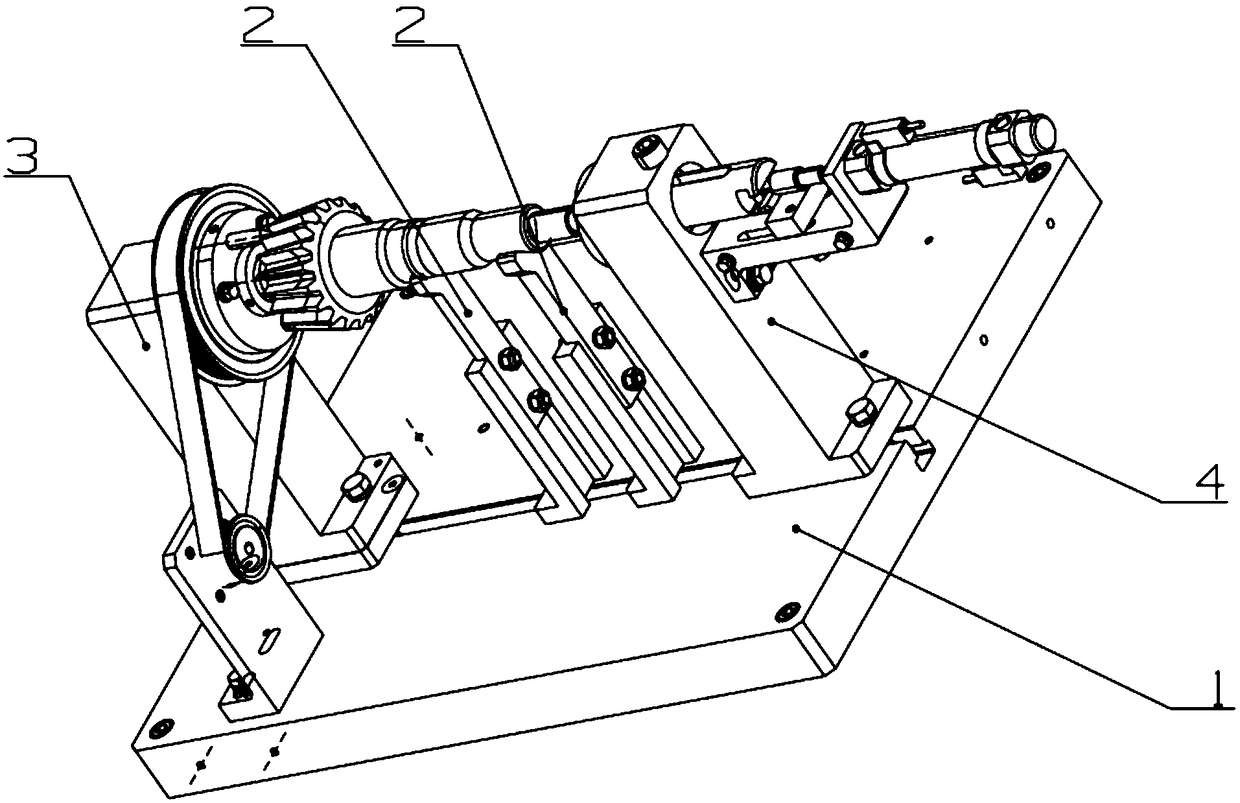

[0022] Such as Figure 1-Figure 3 As shown: a detection fixture for circular runout of specific shaft parts according to the present invention, including a base 1, a support mechanism 2, a fixed tip mechanism 3 and a movable tip mechanism 3 for workpiece clamping and positioning; the fixed tip mechanism 3 also serves as It has the function of driving the workpiece to rotate. When measuring, it drives the workpiece to rotate one circle, and the measuring instrument can collect data and calculate the circular runout.

[0023] The support mechanism 2 includes a support plate 2-1 and a support seat 2-2, the support seat 2-2 has a waist-shaped hole, and the support plate 2-1 and the support seat 2-2 are connected by bolts.

[0024] The fixed top mechanism 3 includes a backing plate 3-6, a fixed top seat 3-4, a fixed top 3-10, a large synchronous pulley 3-9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com