Intelligent dust removal system in coal mine and use method of system

A dust removal system and mine technology, applied in mine/tunnel ventilation, dust prevention, mining equipment, etc., can solve problems such as inability to remove dust, casualties, mine equipment, adjustment of difficult-to-spray objects, etc., to achieve good protection and intelligent effects , good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

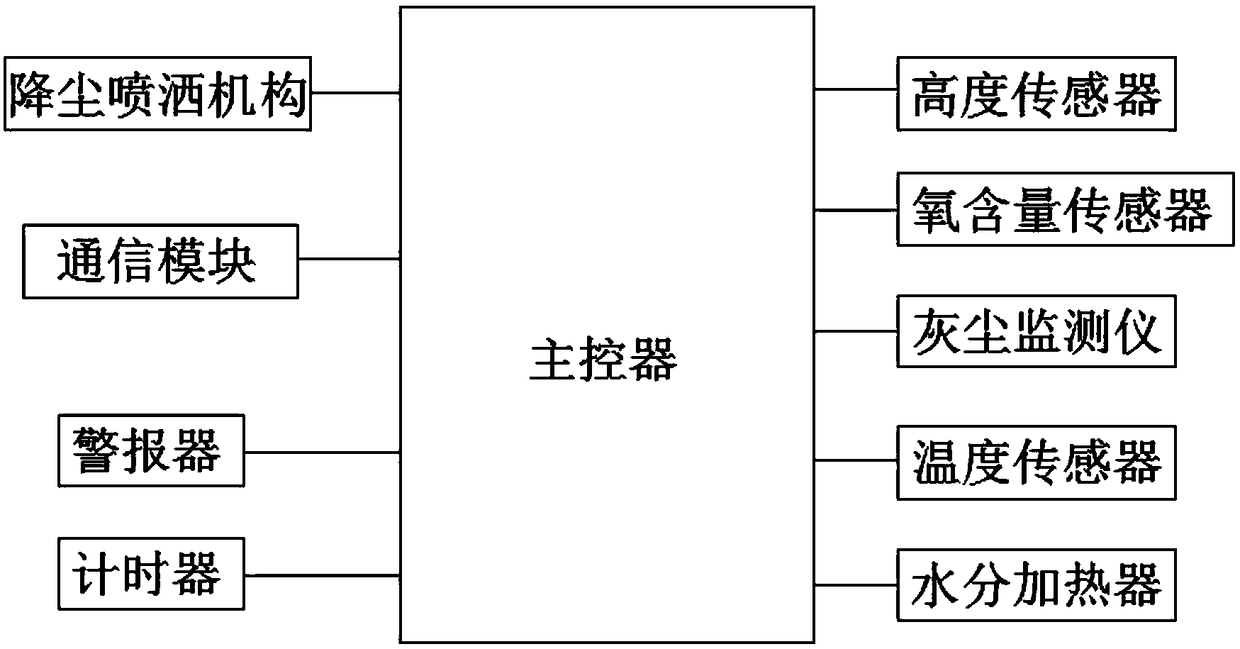

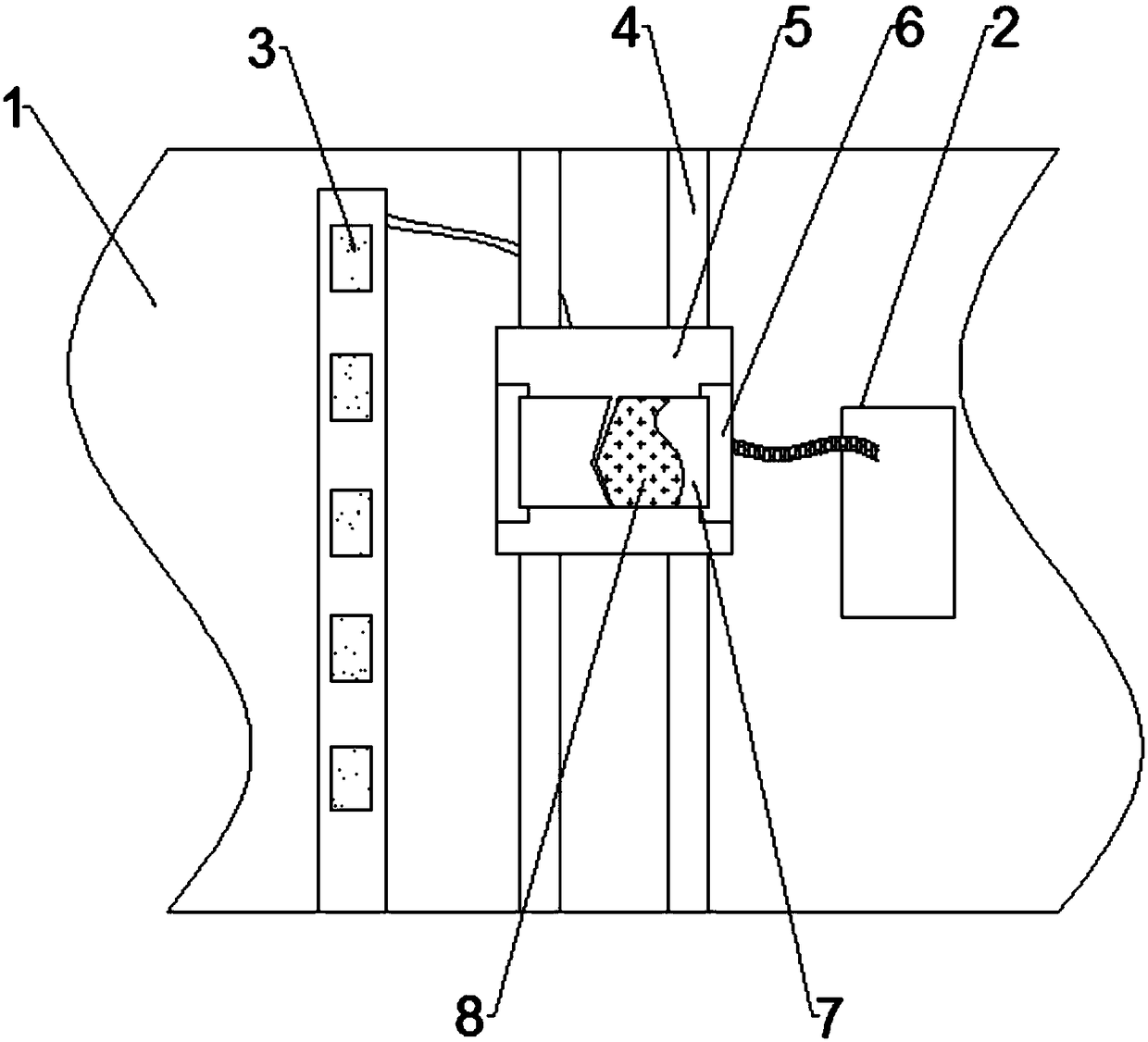

[0042] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0043] An intelligent dust removal system in a mine, including:

[0044] roadway wall 1;

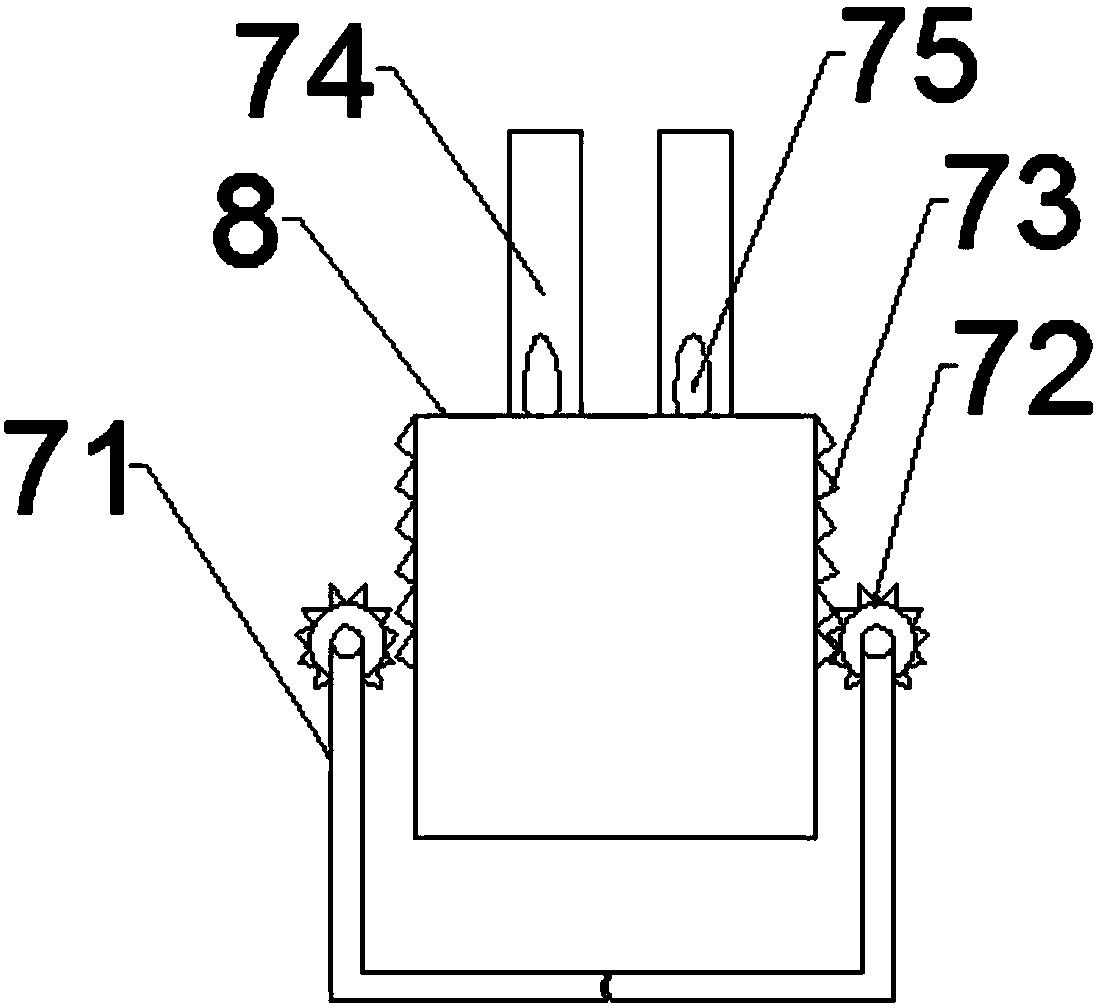

[0045] Dust reduction and spraying mechanism, the dust reduction and spraying mechanism includes a spraying box 5 and a spraying head 8, and the spraying box 5 moves up and down along the vertical track 4 on the roadway wall 1; the spraying head 8 is installed on the spraying box 5 In, and through the control command of the main controller, it enters and exits the spraying box 5;

[0046] Dust monitor, the dust monitor is used to detect the amount of dust around the spray box 5;

[0047] A height sensor, the height sensor is used to detect the distance between the bottom surface of the spray box 5 and the ground;

[0048] A temperature sensor, which is used to detect the temperature at the same level as the spray box 5 in the roadway;

[0049] A main controller, the main controller receives sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com