Pumping unit automatic-control equipment capable of achieving automatic parameter adjustment without load sensor

A load sensor and automatic adjustment technology, which is applied to the automatic control system of drilling, drilling equipment, and production fluids, can solve the problems of wasting manpower, affecting the accuracy of measurement results, and affecting reliability, so as to avoid under-pumping and empty pumping, Avoid the effects of easy aging and work adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

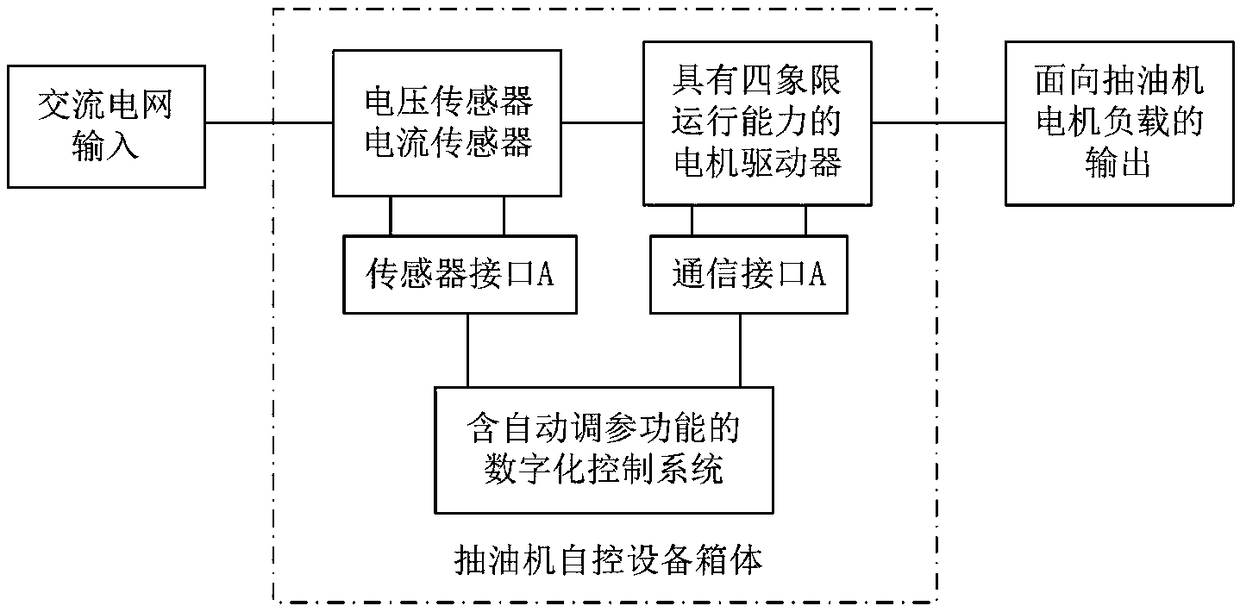

[0037] The AC power grid supplies power to the self-control equipment of the pumping unit that does not need a load sensor to realize automatic parameter adjustment. The voltage sensor and current sensor perform electrical signal detection, and the adaptive active parameter adjustment digital control link collects the input AC voltage and AC current signals through the sensor interface. Calculate the input power factor, optimize the running state of the motor according to the theoretical implementation basis of the present invention, and realize self-adaptive active parameter adjustment corresponding to the working conditions of the pumping unit, thereby obtaining the motor running state control signal for the four-quadrant power drive link, Make the four-quadrant power drive link output the power required for the operation of the AC motor with the characteristics of automatic parameter adjustment; when implementing automatic parameter adjustment, in order to avoid the waxing pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com