NoveL decorative Leather based on skeLeton and preparation method of noveL decorative Leather

A technology for decorative leather and skeleton, applied in the direction of construction, building structure, covering/lining, etc., to achieve the effect of good stiffness, good softness, and improved hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

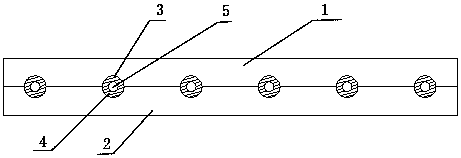

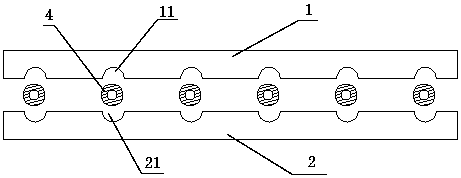

[0026] like figure 1 and 2 As shown, a novel skeleton-based decorative leather includes a base material layer 2, a skeleton, a decorative layer 1, and a binder 4. The components and parts by weight of the substrate layer 2 are as follows: 100 parts of PVC resin, 4 parts of stabilizer, 3 parts of foaming agent, and 30 parts of calcium carbonate; the components and parts by weight of the decorative layer 1 are as follows: 100 parts of PVC resin 40 parts, 40 parts of plasticizer, 10 parts of color cake; The plasticizer can preferably be DOP dioctyl phthalate. The skeleton includes a plurality of twisted fiber filaments 5; the twisted fiber filaments 5 include glass fiber filaments and Modal fiber filaments; the twisted glass fiber filaments and Modal fiber filaments are twisted to form twisted fiber filaments 5 ; The twisted fiber filament 5 is formed by twisting 1000 modal fiber filaments and 1400 glass fiber filaments; the diameter of the glass fiber filaments and the modal f...

Embodiment 2

[0034] like figure 1 and 2 As shown, a novel skeleton-based decorative leather includes a base material layer 2, a skeleton, a decorative layer 1, and a binder 4. The components and parts by weight of the substrate layer 2 are as follows: 100 parts of PVC resin, 4.5 parts of stabilizer, 3.5 parts of foaming agent, and 35 parts of calcium carbonate; the components and parts by weight of the decorative layer 1 are as follows: 100 parts of PVC resin Parts, 45 parts of plasticizer, 15 parts of color cake; Plasticizer can preferably be DOP dioctyl phthalate. The skeleton includes a plurality of twisted fiber filaments 5; the twisted fiber filaments 5 include glass fiber filaments and Modal fiber filaments; the twisted glass fiber filaments and Modal fiber filaments are twisted to form twisted fiber filaments 5 ; The twisted fiber filament 5 is formed by twisting 1100 modal fiber filaments and 1300 glass fiber filaments; the diameter of the glass fiber filaments and the modal fibe...

Embodiment 3

[0042] like figure 1 and 2 As shown, a novel skeleton-based decorative leather includes a base material layer 2, a skeleton, a decorative layer 1, and a binder 4. The components and parts by weight of the substrate layer 2 are as follows: 100 parts of PVC resin, 5 parts of stabilizer, 4 parts of foaming agent, and 40 parts of calcium carbonate; the components and parts by weight of the decorative layer 1 are as follows: 100 parts of PVC resin 50 parts, 50 parts of plasticizer, 20 parts of color cake; The plasticizer can preferably be DOP dioctyl phthalate. The skeleton includes a plurality of twisted fiber filaments 5; the twisted fiber filaments 5 include glass fiber filaments and Modal fiber filaments; the twisted glass fiber filaments and Modal fiber filaments are twisted to form twisted fiber filaments 5 ; The twisted fiber filament 5 is formed by twisting 1200 Modal fiber filaments and 1200 glass fiber filaments; the diameter of the glass fiber filaments and Modal fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com