Anti-floating dense construction method of hollow floor slab and thin-wall square box used in same

A hollow floor slab and construction method technology, applied in the direction of floor slabs, building components, buildings, etc., can solve the problems of easy occurrence of holes, waste of steel bars and labor, and poor lateral displacement control effect of square boxes, etc., to achieve enhanced strength and tightness. The effect of saving steel bars and workers' binding points, and improving the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is illustrated below in conjunction with the accompanying drawings.

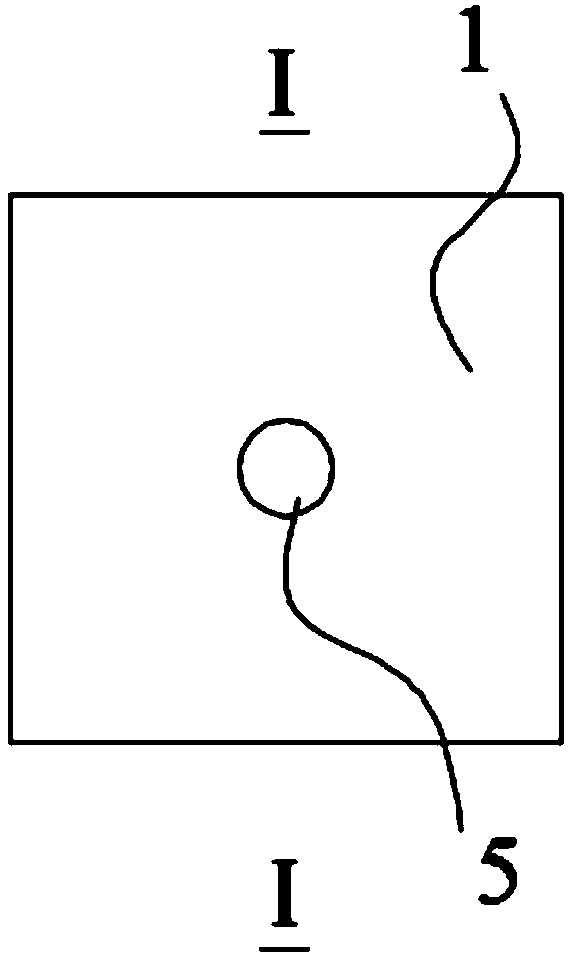

[0032] As shown in the figure, a thin-walled square box for anti-floating and dense construction of hollow floor slabs, the thin-walled square box 1 has a regular polygonal cross section and an isosceles trapezoidal longitudinal section, which together form a closed box structure with a large upper part and a smaller lower part. The middle part of the box structure is provided with a through-hole 5 that runs through the upper and lower sides, and the through-hole 5 is sealed and isolated from the inner space of the airtight box; Reinforcing groove 9.

[0033] More preferably, the bottom of the thin-walled square box 1 is provided with anti-floating tension ribs, and the anti-floating tension ribs are provided with installation holes for pulling knots. The transverse section of the thin-walled square box 1 is a regular quadrilateral or regular octagon. This embodiment uses The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com