Pressure foot of sewing machine

A sewing machine presser foot and roller technology, which is applied to the sewing machine presser foot field, can solve the problems of reduced lifespan and serious performance of the presser foot, and achieve the effects of high work efficiency, convenient production and use, and significant benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

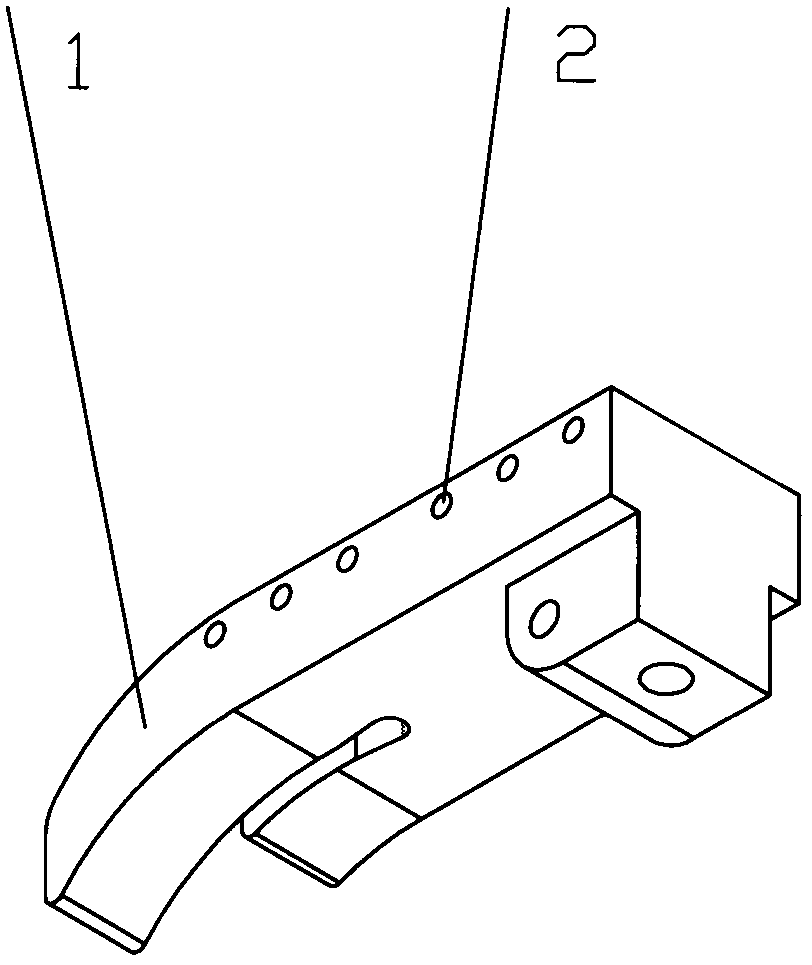

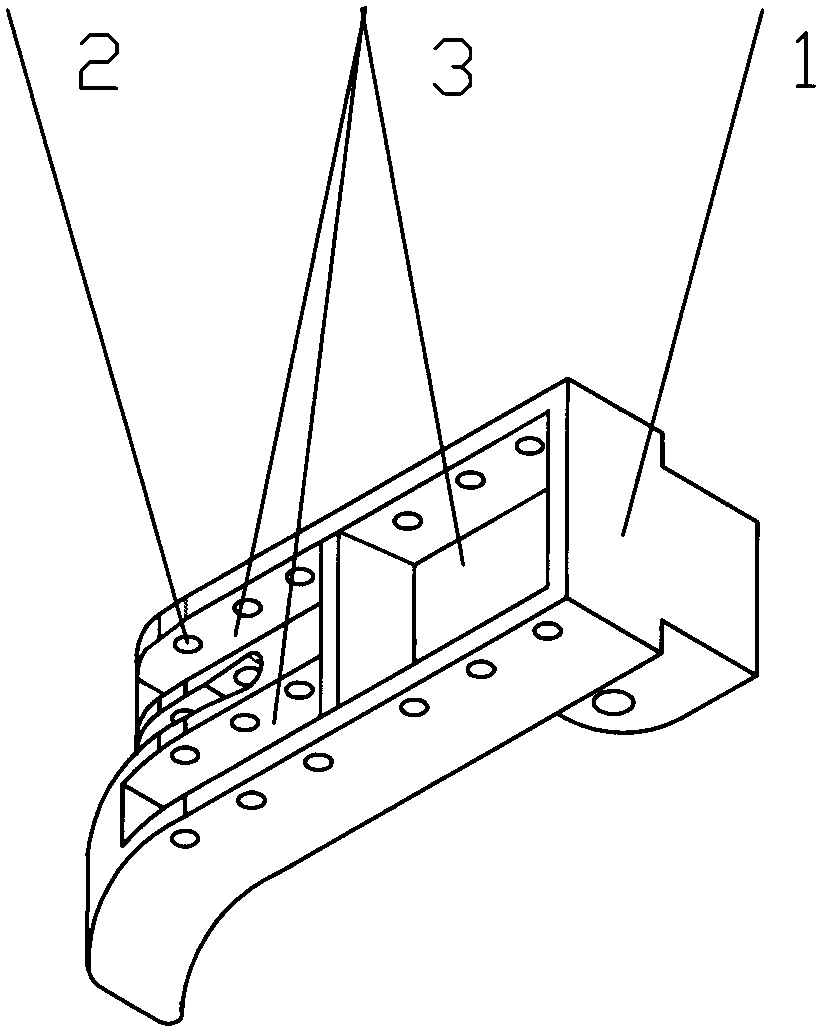

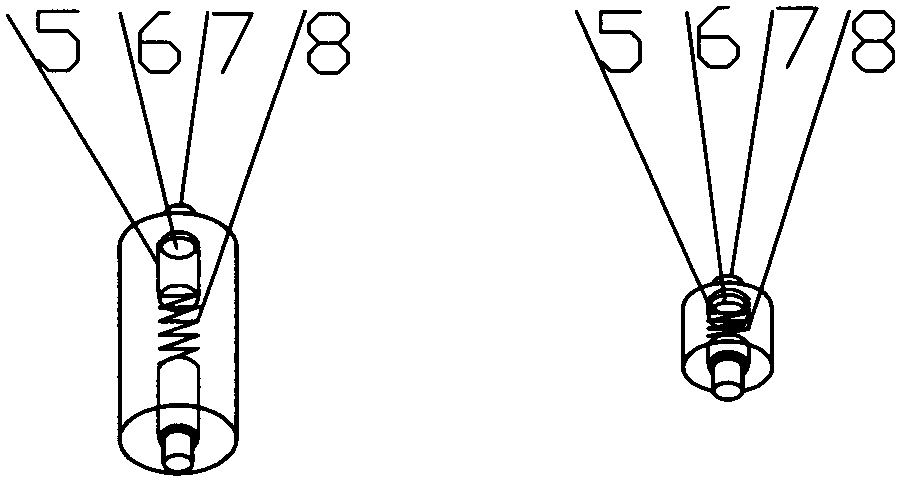

[0016] Below in conjunction with accompanying drawing, the present invention will be further described: figure 1 to attach Figure 7 It can be seen that a sewing machine presser foot of the present invention will include a presser body 1, a roller 4, and a rubber thread belt 10, wherein the bottom of the presser body 1 is provided with three grooves 3, and the depth of the three grooves 3 Same, width is one groove wide, two grooves are narrow; Both sides of described groove 3 are all correspondingly provided with more than three pairs of small holes 2, and described small holes 2 are all located on the same horizontal line, and described horizontal line reaches The distance from the upper edge of the groove 3 is smaller than the distance to the bottom surface of the groove 3, and this distance difference is slightly greater than the thickness of the rubber cord 10; each pair of small holes 2 is provided with a roller 4 adapted to the groove 3, The diameter of the roller 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com