Cloth spreading device for circular-disc knitting machine

A knitting machine and disc technology, applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problem of uneven tension of knitted fabrics, and achieve the effect of quick and convenient assembly and disassembly and adjustment, improving quality and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

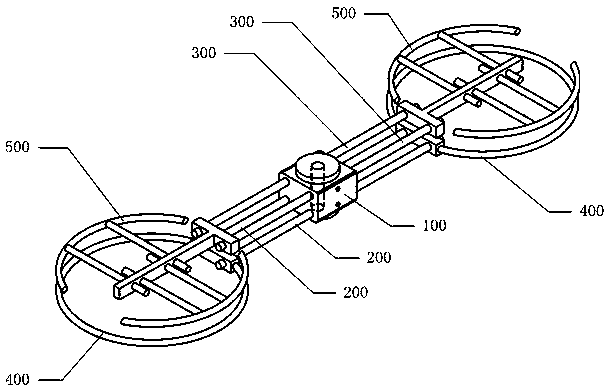

[0023] The present invention provides a spreading device for a circular knitting machine. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

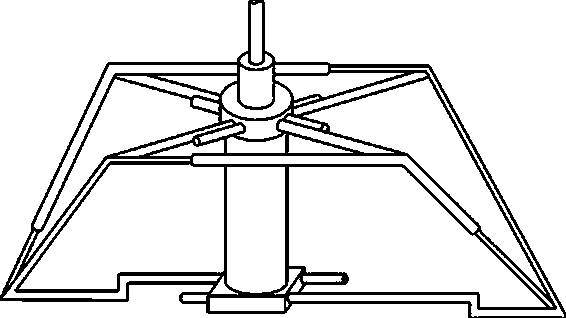

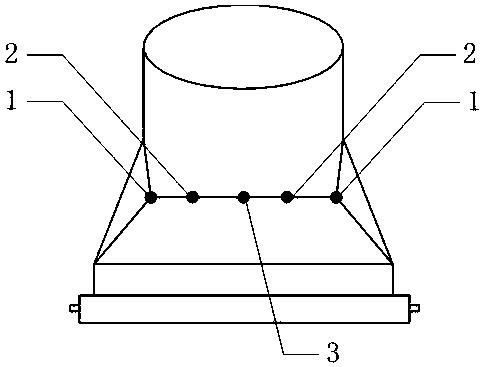

[0024] see Figure 3-Figure 6 , the present invention provides a spreading device for a circular knitting machine, the spreading device includes a bushing 100, a first guide rod 200 and a second guide rod arranged vertically and parallelly on the bushing 100 300, and two sets of spreading rings arranged symmetrically on both sides of the shaft sleeve 100, each set of spreading rings respectively includes a main spreading ring 400 and a secondary spreading ring arranged above the main spreading ring Ring 500; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com