Method for preparing unidirectional wet conduction polyester plaid jacquard cloth knitted fabrics

A technology of one-way moisture guide and knitted fabrics, which is applied in the field of textiles, can solve the problems of trouble, long time consumption, expensive yarn cost, etc., and achieve the effects of reducing costs, increasing purchasing power, and reducing the amount of fabrics used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a one-way moisture-guiding full polyester grid jacquard knitted fabric, the raw materials of the one-way moisture-guiding full polyester grid jacquard knitted fabric include polyester filament DTY75D / 72F and polyester filament FDY 50D / 24F, including the following steps :

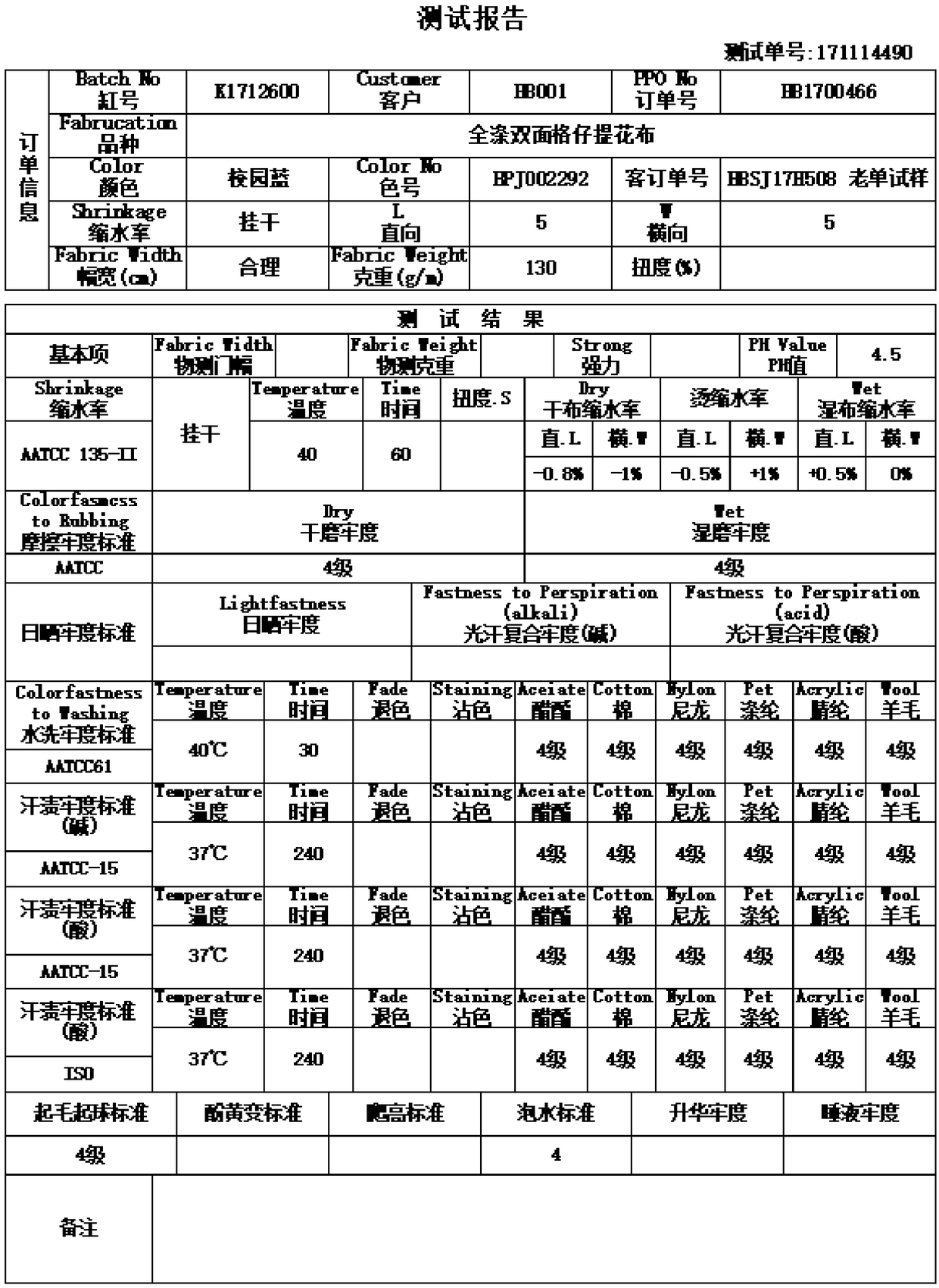

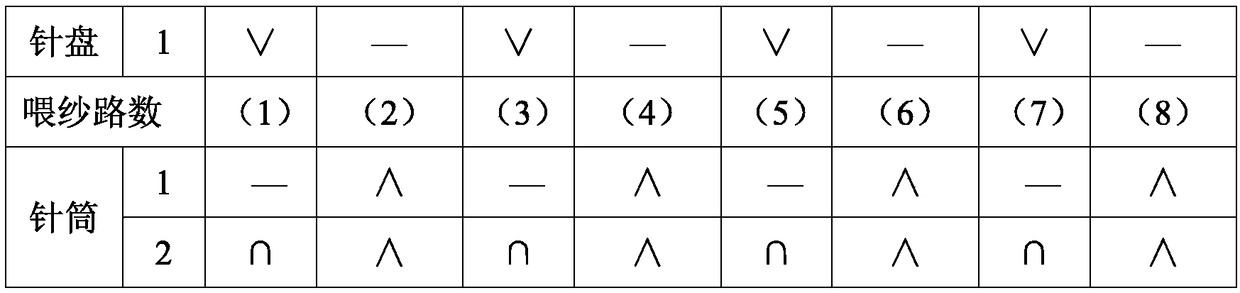

[0037] 1) Weaving: Send the above raw materials into the ordinary double-sided weft knitting large circular machine for weaving to obtain the gray cloth. The needle disc adopts AAA, the needle cylinder adopts AAB needle row, and the triangle arrangement of the upper machine is as shown in the table and figure 1 Shown:

[0038]

[0039] Among them, ∧ or ∨ means circle, ∩ or ∪ means tuck circle, - means floating line,

[0040] Specific yarn threading methods: yarn feeding routes (1), (2), (3), (4), (6) and (8) to wear polyester filament DTY75D / 72F, among which yarn feeding routes (1) and The line length of (3) is 28~30cm / 100 needles, and the line length of (2), (4), (6) and (...

Embodiment 2

[0054] A method for preparing a one-way moisture-guiding full polyester grid jacquard knitted fabric, the raw materials of the one-way moisture-guiding full polyester grid jacquard knitted fabric include polyester filament DTY75D / 72F and polyester filament FDY 50D / 24F, including the following steps :

[0055] 1) Weaving: Send the above raw materials into the ordinary double-sided weft knitting large circular machine for weaving to obtain the gray cloth. The needle disc adopts AAA, the needle cylinder adopts AAB needle row, and the triangle arrangement of the upper machine is as shown in the table andfigure 1 Shown:

[0056]

[0057]

[0058] Among them, ∧ or ∨ means circle, ∩ or ∪ means tuck circle, - means floating line,

[0059] Specific yarn threading methods: yarn feeding routes (1), (2), (3), (4), (6) and (8) to wear polyester filament DTY75D / 72F, among which yarn feeding routes (1) and The line length of (3) is 28~30cm / 100 needles, the line length of (2), (4), (6)...

Embodiment 3

[0072] A method for preparing a one-way moisture-guiding full polyester grid jacquard knitted fabric, the raw materials of the one-way moisture-guiding full polyester grid jacquard knitted fabric include polyester filament DTY75D / 72F and polyester filament FDY 50D / 24F, including the following steps :

[0073] 1) Weaving: Send the above raw materials into the ordinary double-sided weft knitting large circular machine for weaving to obtain the gray cloth. The needle disc adopts AAA, the needle cylinder adopts AAB needle row, and the triangle arrangement of the upper machine is as shown in the table and figure 1 Shown:

[0074]

[0075] Among them, ∧ or ∨ means circle, ∩ or ∪ means tuck circle, - means floating line,

[0076] Specific yarn threading methods: yarn feeding routes (1), (2), (3), (4), (6) and (8) to wear polyester filament DTY75D / 72F, among which yarn feeding routes (1) and The thread length of (3) is 28~30cm / 100 stitches, the thread length of (2), (4), (6) and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com