A kind of preparation method of alkali-resistant water-based metal exterior wall paint

An exterior wall coating and alkali-resistant technology, which is applied to non-metallic paints, anti-corrosion coatings, coatings, etc., can solve the problems of short service life and poor alkali resistance, and achieve long service life, excellent scrub resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

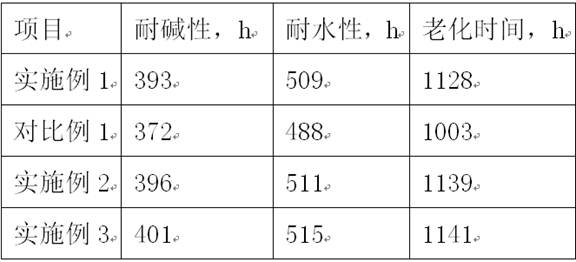

Examples

Embodiment 1

[0015] A preparation method of an alkali-resistant water-based metal exterior wall paint, comprising the following steps:

[0016] (1) In parts by weight, add 18 parts of cerium chloride and 12 parts of yttrium chloride to 190 parts of water, mix and stir evenly, heat it to 75°C, continue to add 36 parts of sodium erucate to it, mix and stir After uniform heat preservation treatment, the alkali-resistant additive is obtained;

[0017] (2) In parts by weight, 58 parts of pure acrylic emulsion, 26 parts of water, 0.1 part of polyglycerol monostearate, 2 parts of tripotassium citrate, 0.8 parts of calcium cyclamate, 8 parts of alkali-resistant Additives, 6 parts of metallic pigment, 0.6 part of wetting and dispersing agent, and 0.2 part of defoaming agent are mixed evenly, and then stirred continuously for 25 minutes to obtain a finished product, wherein the metallic pigment is water-based environmentally friendly copper gold powder.

[0018] Specifically, in the above step (1),...

Embodiment 2

[0022] A preparation method of an alkali-resistant water-based metal exterior wall paint, comprising the following steps:

[0023] (1) In parts by weight, add 20 parts of cerium chloride and 13 parts of yttrium chloride to 195 parts of water, mix and stir evenly, heat it to 80°C, continue to add 40 parts of sodium erucate to it, mix and stir After uniformity and heat preservation treatment, an alkali-resistant additive is obtained;

[0024] (2) In parts by weight, 63 parts of pure acrylic emulsion, 30 parts of water, 0.2 parts of polyglycerol monostearate, 3 parts of tripotassium citrate, 1.0 part of calcium cyclamate, 10 parts of alkali-resistant Additives, 8 parts of metallic pigments, 0.8 parts of wetting and dispersing agent, and 0.3 parts of defoaming agent are mixed evenly, and then stirred continuously for 30 minutes to obtain a finished product, wherein the metallic pigment is water-based environmentally friendly copper gold powder.

[0025] Specifically, in the above...

Embodiment 3

[0029] A preparation method of an alkali-resistant water-based metal exterior wall paint, comprising the following steps:

[0030] (1) In parts by weight, add 23 parts of cerium chloride and 15 parts of yttrium chloride to 200 parts of water, mix and stir evenly, heat it to 85°C, continue to add 42 parts of sodium erucate to it, mix and stir After uniformity and heat preservation treatment, an alkali-resistant additive is obtained;

[0031] (2) In parts by weight, 65 parts of pure acrylic emulsion, 32 parts of water, 0.3 parts of polyglycerol monostearate, 4 parts of tripotassium citrate, 1.2 parts of calcium cyclamate, 13 parts of alkali-resistant Additives, 10 parts of metallic pigment, 0.9 part of wetting and dispersing agent, and 0.5 part of defoamer are uniformly mixed, and then stirred continuously for 35 minutes to obtain a finished product, wherein the metallic pigment is water-based aluminum silver paste.

[0032] Specifically, in the above step (1), the time for hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com