Method for preparing coloring material by using manganese carbonate capable of enabling coloring material with bright color

一种碳酸锰、色料的技术,应用在化学仪器和方法、纤维状填料、无机颜料处理等方向,能够解决色料烧成范围高温性能不佳等问题,达到着色力强、色调鲜艳、反应活性和分散性能提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

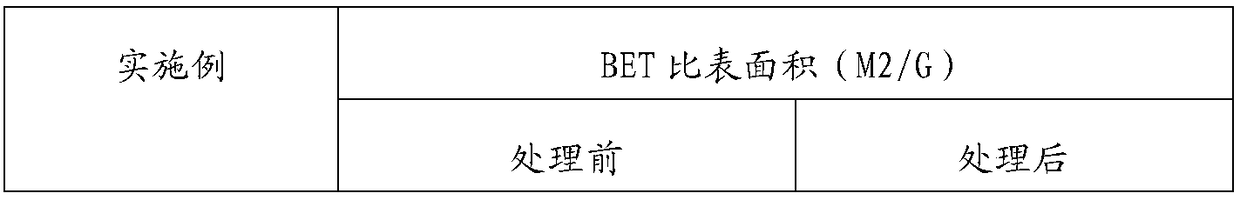

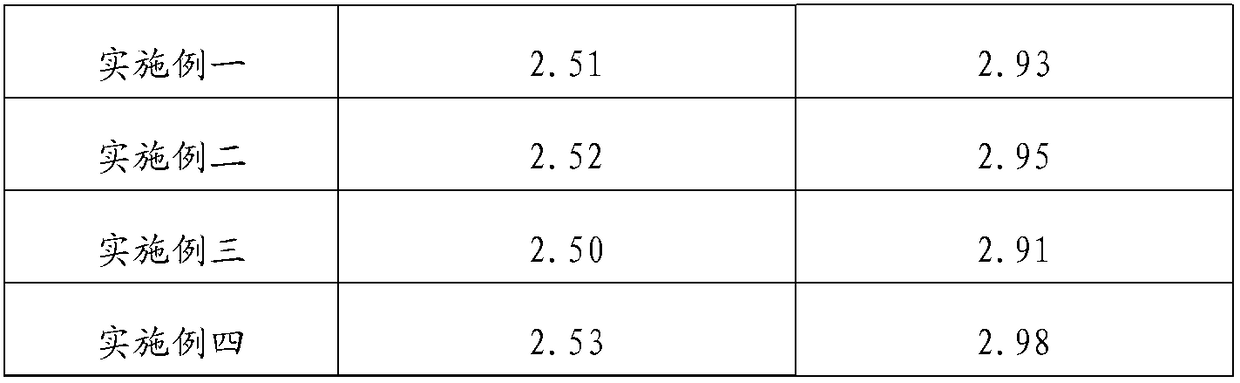

[0029] A kind of method that utilizes manganese carbonate to prepare color material, the manganese carbonate that particle size is 10 μ m is subjected to surface modification treatment, then the manganese carbonate after surface modification treatment is subjected to aging treatment under the condition of 30 ℃, and the time of described aging treatment is 48h, then dry and grind the manganese carbonate after stale treatment in sequence, and then mix with auxiliary raw materials, the auxiliary raw materials are a mixture of alumina, aluminum hydroxide, calcium phosphate and calcium chloride. Dry the stale-treated manganese carbonate at a temperature of 120° C. for 200 minutes, and then grind the stale-treated manganese carbonate until the particle size of the manganese carbonate is 3 μm; the auxiliary raw material is. A mixture is formed, and the mixture is calcined from 0°C to 1150°C at a heating rate of 80°C / h, and then the calcined mixture is kept at 1130°C for 1 hour, and th...

Embodiment 2

[0031] A kind of method that utilizes manganese carbonate to prepare color material, carry out surface modification treatment to the manganese carbonate of particle size of 12 μ m, then carry out stale treatment at 50 ℃ of conditions with the manganese carbonate after surface modification treatment, the time of described stale treatment is 60h, then dry and grind the aged manganese carbonate in sequence, and then mix with auxiliary raw materials, the auxiliary raw materials are a mixture of alumina, aluminum hydroxide, calcium phosphate and calcium chloride. Dry the stale-treated manganese carbonate at a temperature of 150° C. for 280 minutes, and then grind the stale-treated manganese carbonate until the particle size of the manganese carbonate is 4.5 μm; the auxiliary raw material is. A mixture is formed, and the mixture is calcined from 0°C to 1150°C at a heating rate of 100°C / h, and then the calcined mixture is kept at 1200°C for 2 hours, and the heat-preserved mixture is s...

Embodiment 3

[0033] A method for preparing colorants by using manganese carbonate, which involves surface modification treatment of manganese carbonate with a particle size of 11 microns, and then stale treatment of the manganese carbonate after surface modification treatment at 40°C, and the time for the stale treatment After 55 hours, the stale processed manganese carbonate is dried and ground in sequence, and then mixed with auxiliary raw materials, the auxiliary raw materials are a mixture of alumina, aluminum hydroxide, calcium phosphate and calcium chloride. Dry the stale-treated manganese carbonate at a temperature of 135° C. for 240 minutes, and then grind the stale-treated manganese carbonate until the particle size of the manganese carbonate is 4 μm; the auxiliary raw material is. A mixture is formed, and the mixture is calcined from 0°C to 1150°C at a heating rate of 90°C / h, and then the calcined mixture is kept at 1180°C for 1.5 hours, and the heat-preserved mixture is sequentia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com