Gumming machine for ecological board production

A glue applicator and eco-board technology, which is applied in the direction of coating, glue container, wooden veneer joint, etc., can solve the problem of time difference in applying glue, etc., to reduce the probability of cracking the board, and the effect of gluing is good , the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

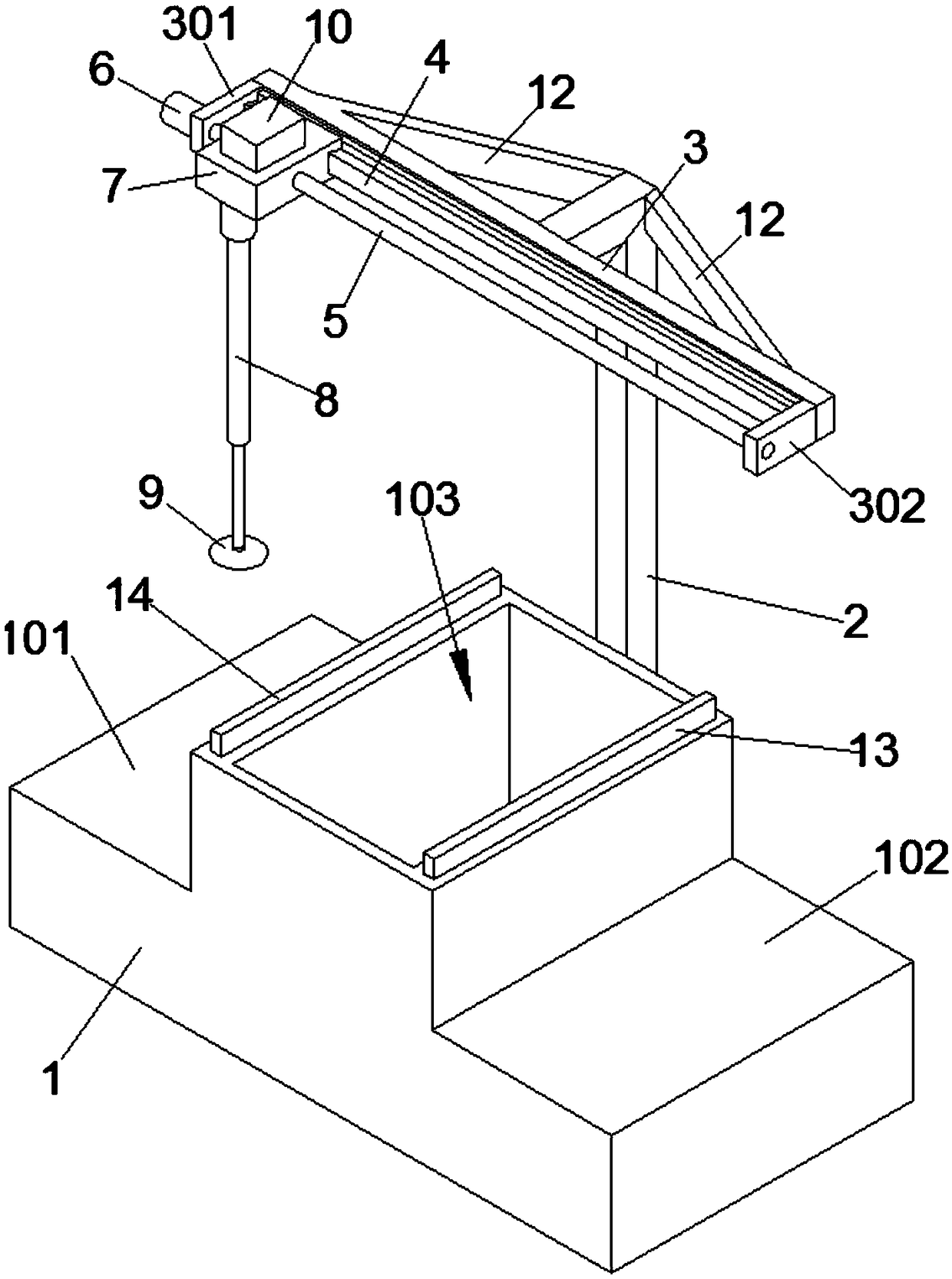

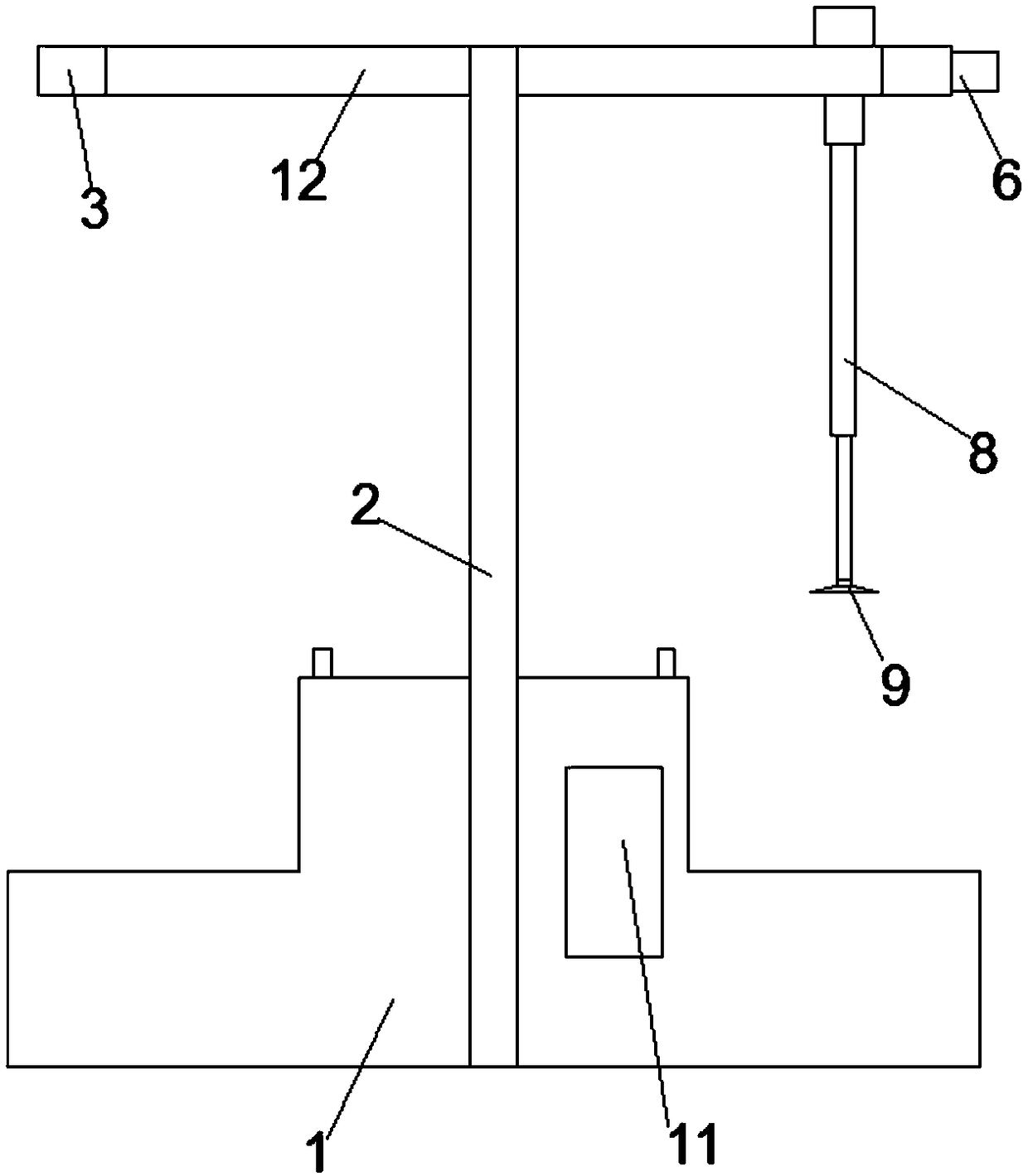

[0032] In this embodiment, a gluing machine for ecological board production includes a base 1, an L-shaped bracket 2, a linear support block 3, a linear guide rail 4, a screw rod 5, a servo motor 6, a slider 7, an electric push rod 8, Vacuum chuck 9, vacuum pump 10 and power supply 11. The above-mentioned base 1 is roughly in the shape of a "convex" shape. The left and right parts of the base 1 are respectively provided with a left stacking platform 101 and a right stacking platform 102 for stacking plates. Users can stack the plates to be glued. On the left stacking platform 101, the boards to be bonded are stacked on the right stacking platform 102, and a glue pool 102 for containing glue is also arranged on the base 1, and the glue pool 103 is arranged on the above-mentioned left stacking platform 101 and the right side. Between stacking platforms 102. One end of the above-mentioned L-shaped support 2 is connected to the rear side of the above-mentioned base 1, and the abo...

Embodiment 2

[0039] This embodiment is used as an improved implementation of Embodiment 1. In this embodiment, a scraper 13 is arranged along the front and rear directions between the glue pool 103 on the base 1 and the right stacking platform 102. The scraper 13 is a square plate. The top surface is a plane, which limits the height of the top surface of the scraper 13 from the ground to a slightly lower height than the lower surface of the board that has been glued and moves to the right. When the board that has been glued moves to the right and passes the scraper 13, the scraper 13 can scrape the thickness of the glue on the plate, so as to further ensure the consistency of the glue viscosity on the entire plate surface of the plate.

Embodiment 3

[0041] This embodiment is used as an improved implementation of Embodiment 2. In this embodiment, a cleaning board 14 is also provided along the front and rear directions between the left stacking platform 101 and the glue pool 103 on the base 1, and the top of the cleaning board 14 is provided with a Rag, the cleaning plate 14 is a square plate, its top is a plane, and the height of the upper surface of the above-mentioned rag is the same as the height of the lower surface of the plate to be glued when it moves to the right. During the process of moving the boards from the left stacking platform 101 to the top of the glue pool 103, the rag will clean the lower surface of the boards, so that the surface of the boards to be glued will be cleaner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com