A ring die reaming device for feed

A ring die and feed technology, which is used in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems that the hole is difficult to meet the requirements, the human hand is unstable, and the operability is poor. The effect of solving the problem of punching, saving labor, and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

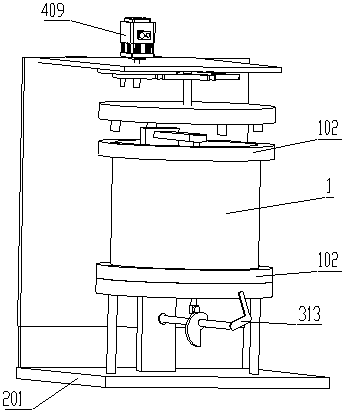

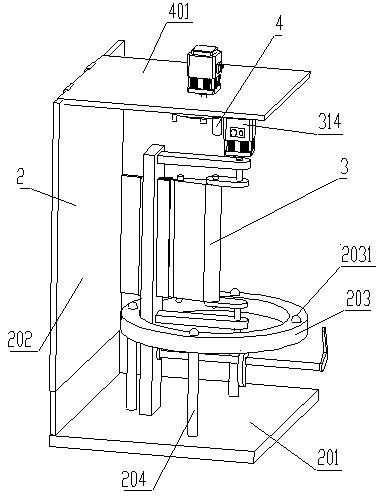

[0046] see Figure 1 to Figure 8 , the present invention provides a ring die reaming device for feed, comprising a ring die 1, a fixing mechanism 2 of the ring die 1, a drilling mechanism 3 arranged on the fixing mechanism 2 and a ring die 1 mounted on the top of the fixing mechanism 2 Turning mechanism 4;

[0047]The ring die 1 comprises a ring die body and ring die retaining rings 102 arranged at both ends of the ring die body, the ring die retaining ring 102 is provided with evenly distributed ring die retaining holes 103, and the ring die 1 body is provided with several through holes; The mechanism 2 includes a fixed base 201, and one side of the fixed base 201 is vertically provided with a telescopic support plate 202; the axial direction of the ring mold is perpendicular to the fixed base 201 and placed on the fixed mechanism 2;

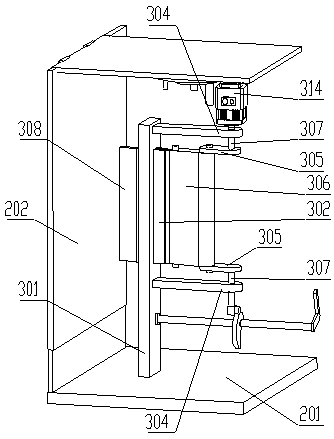

[0048] Drilling mechanism 3 comprises and is fixed on the fixed base 201, and the drilling limit plate 301 perpendicular to the fixed base 20...

Embodiment 2

[0073] On the basis of Embodiment 1, different from Embodiment 1, the displacement mechanism also includes a connection block 309 arranged on one side of the linkage mechanism fixing rod 304, and the connection block 309 is fixedly arranged on the side away from the drilling limit plate 301 There is a roller 310 perpendicular to the surface, a nautilus cam 311 is arranged on the underside of the roller 310, the wheel surface of the roller 310 is attached to the cam surface of the nautilus cam 311, and the cam rotation shaft 312 is set through on the nautilus cam 311;

[0074] One end of the cam rotating shaft 312 is hinged to the drilling limit plate 301 , and a rocking handle 313 is provided at the end of the other end.

[0075] When working, each displacement of the needle drill of the drilling mechanism 3 is a row of radial single-row through-holes; the first week is counted from one row, which is the first 3 5 7th row of radial single-row through-holes. row; after rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com