A kind of spraying mechanism and spraying method for inner surface of cylindrical container

An inner surface, cylindrical technology, applied in the direction of spraying devices, etc., can solve the problems of narrow application range, single product, high product size and weight requirements, and achieve high spraying efficiency, uniform spraying surface and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

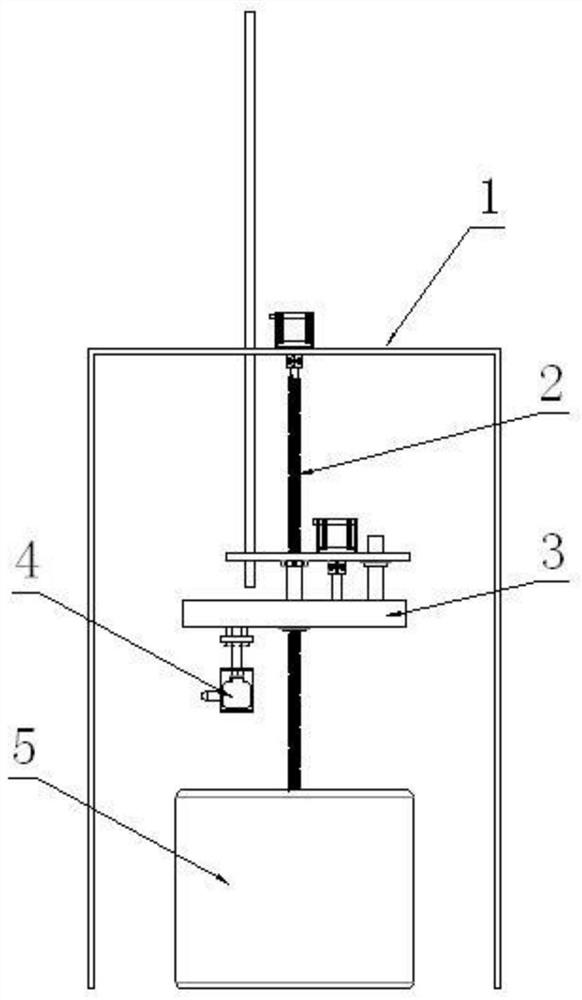

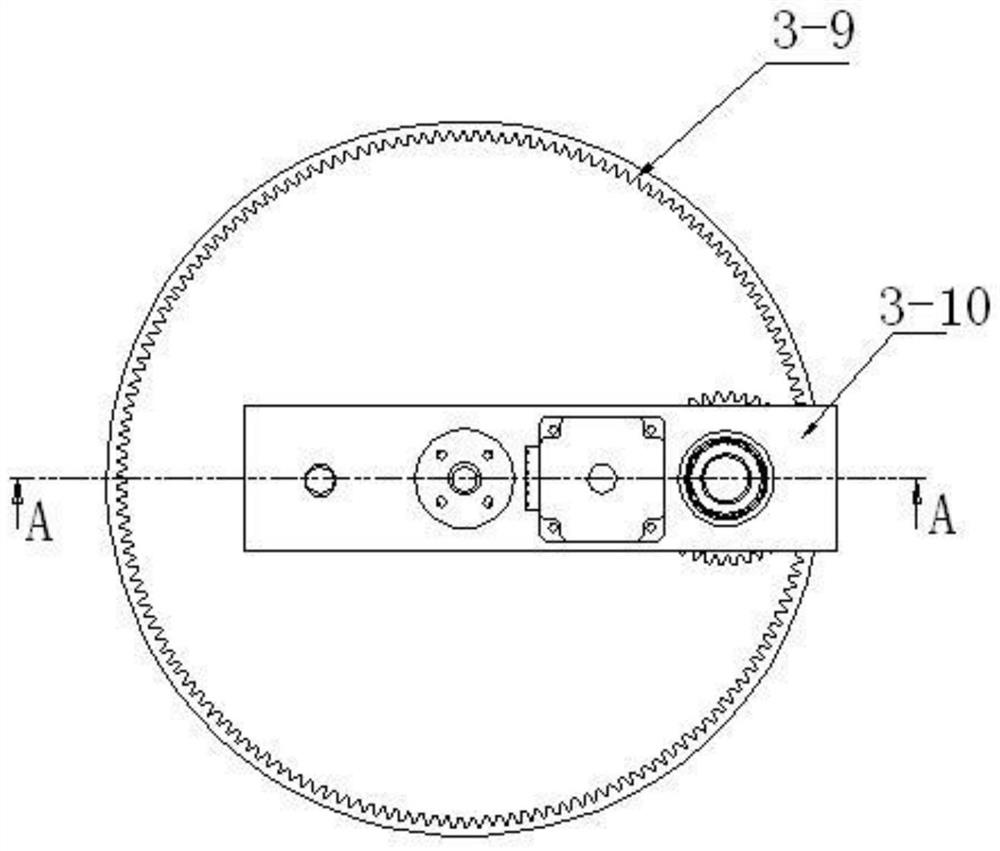

[0025] As shown in the drawings, a spraying mechanism for the inner surface of a cylindrical container includes a supporting mechanism 1 , a moving mechanism 2 , a rotating mechanism 3 and a spraying mechanism 4 . The inside of the support mechanism 1 has a space for accommodating the workpiece 5. Considering the simplicity and reliability of the structural design, the support mechanism 1 in this embodiment is composed of at least two door-shaped support frames 1-1 whose tops are connected together. . The moving mechanism 2 includes a first motor 2-1, a ball screw 2-2, and a screw nut 2-3. The first motor 2-1 is fixedly installed on the top of the support mechanism 1, and the ball screw The bar 2-2 is vertically arranged inside the support mechanism 1 and connected with the output shaft of the first motor 2-1 through a coupling. The rotating mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com