Stirring device for sewage treatment with automatic dosing function

A technology for automatic dosing and sewage treatment. It is used in mixer accessories, transportation and packaging, chemical/physical processes, etc. It can solve problems such as polluting the environment, inability to mix evenly with sewage treatment agents, and sewage flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

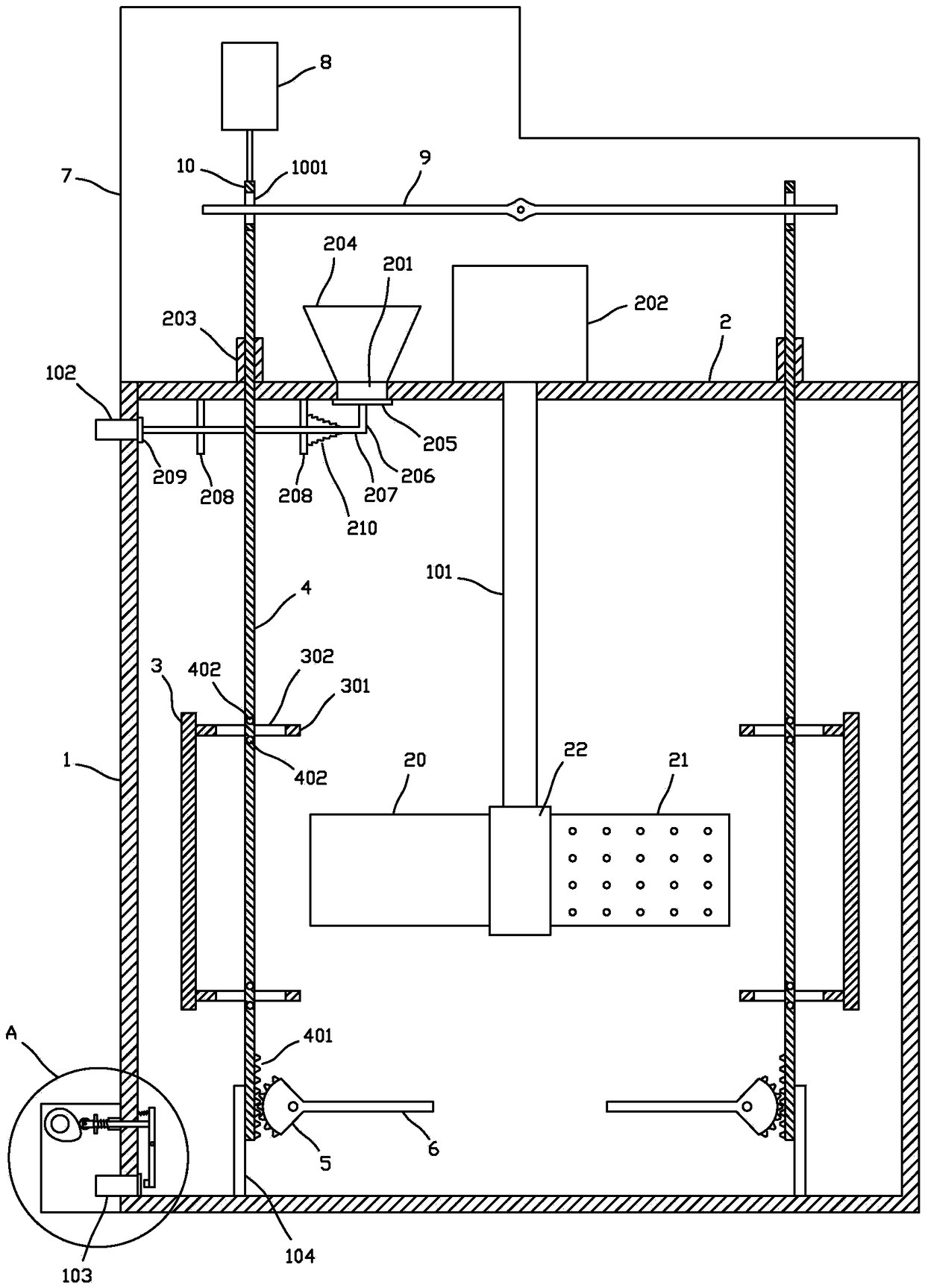

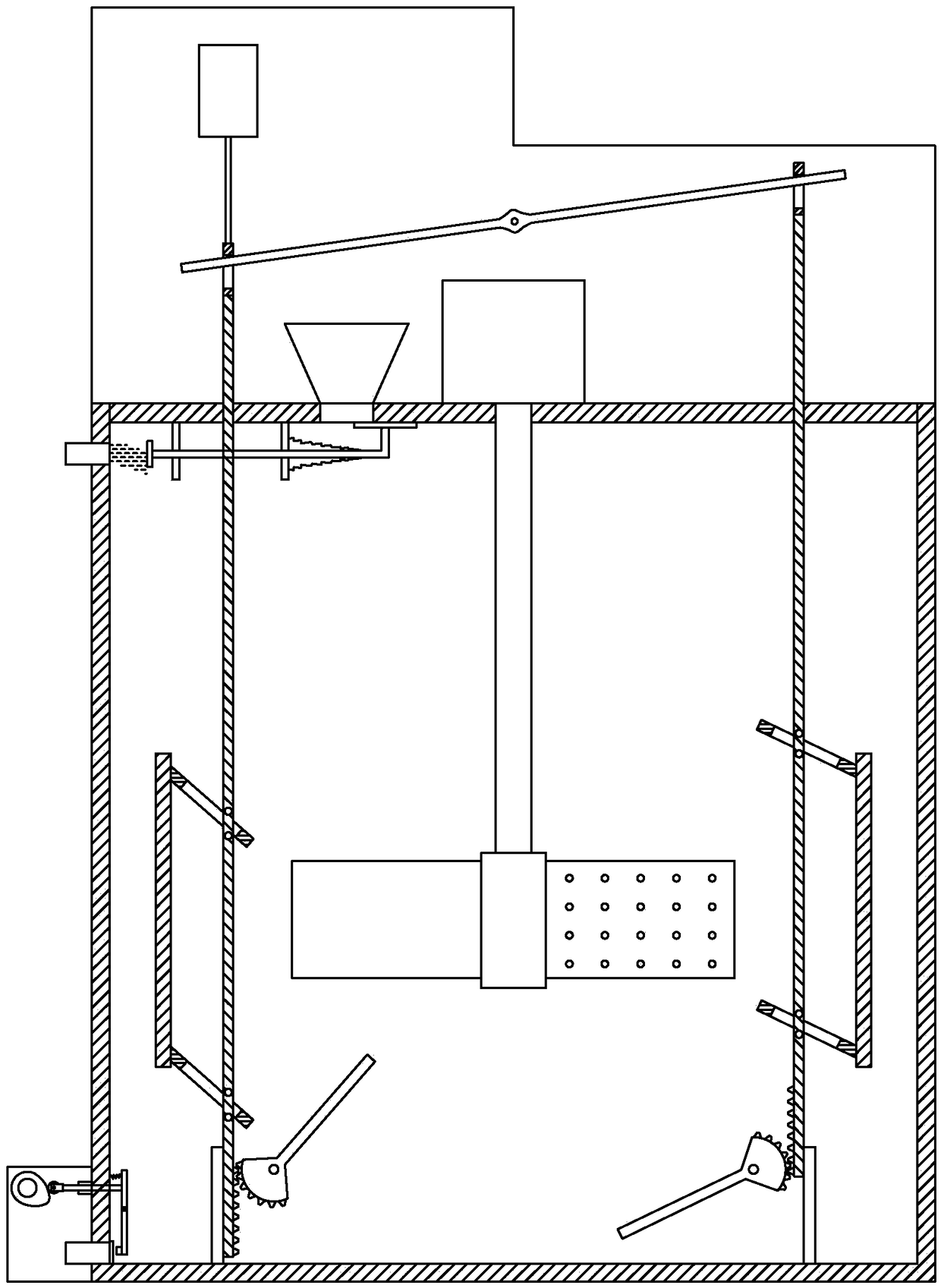

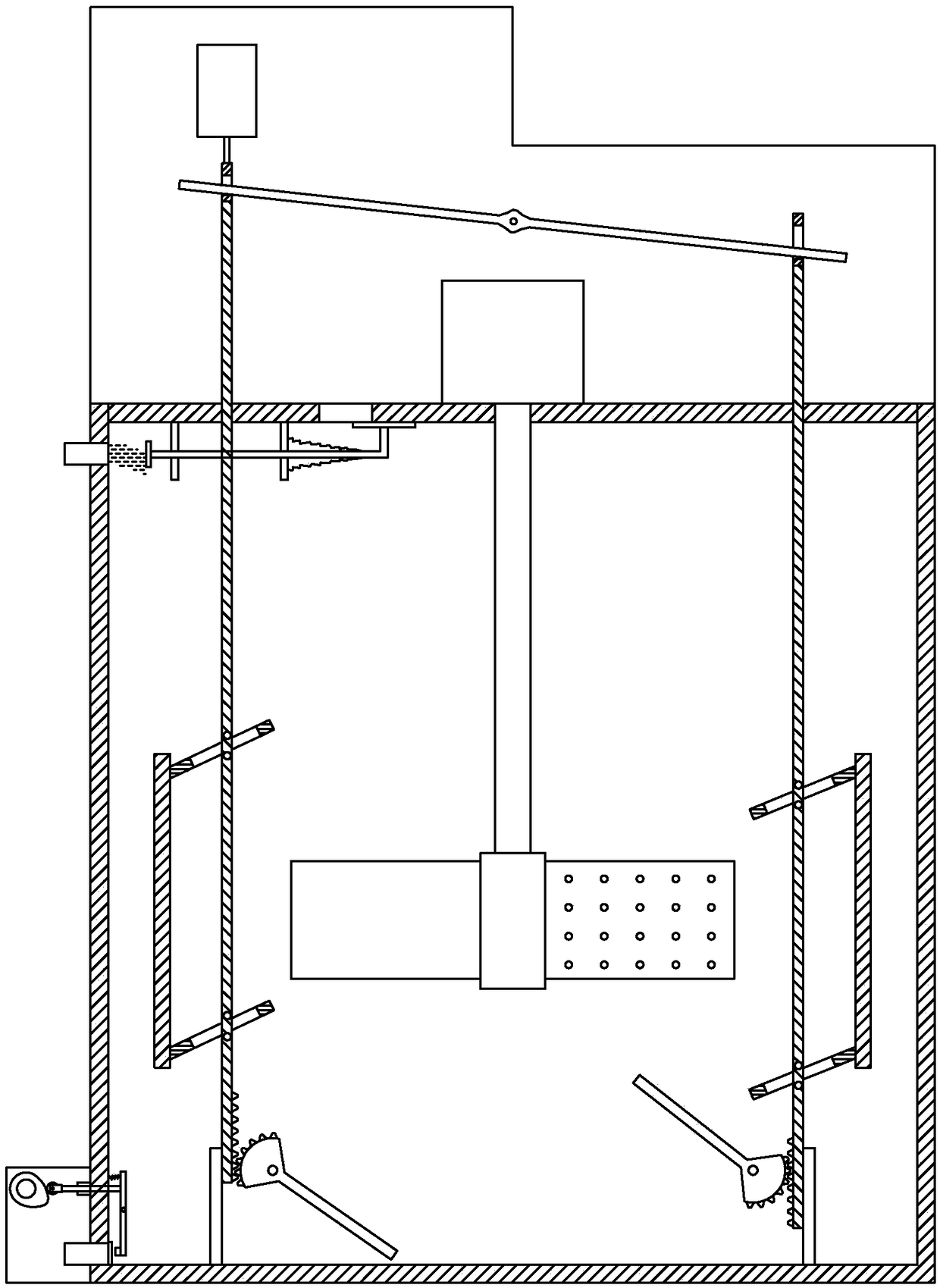

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] Depend on Figure 1 to Figure 10As shown, the stirring device of the present invention is used for sewage treatment and has the function of automatic dosing. It includes a barrel body 1, and a rotating shaft 101 is arranged in the barrel body 1. The stirring paddle assembly, the upper part of the outer peripheral wall of the barrel body 1 is provided with a water inlet pipe 102, the water inlet pipe 102 is used to connect sewage into the barrel body 1, and the lower part of the outer peripheral wall of the barrel body 1 is provided with a water outlet pipe 103, and the water outlet pipe 103 is used In order to discharge the sewage from the barrel body 1, a cover plate 2 is provided on the top of the barrel body 1, and a dosing port 201 and a first motor 202 for driving the rotating shaft 101 to rotate are arranged on the cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com