Homogenizer for preparing oil anti-foaming agent for electric power

A technology of oil and anti-foaming agent for electric power, applied in chemical instruments and methods, dissolving, mixer and other directions, can solve the problems of high kinematic viscosity of oil anti-foaming agent raw material and poor homogenization effect of oil anti-foaming agent raw material, etc. To achieve the effect of improving the homogenization effect and improving the homogenization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

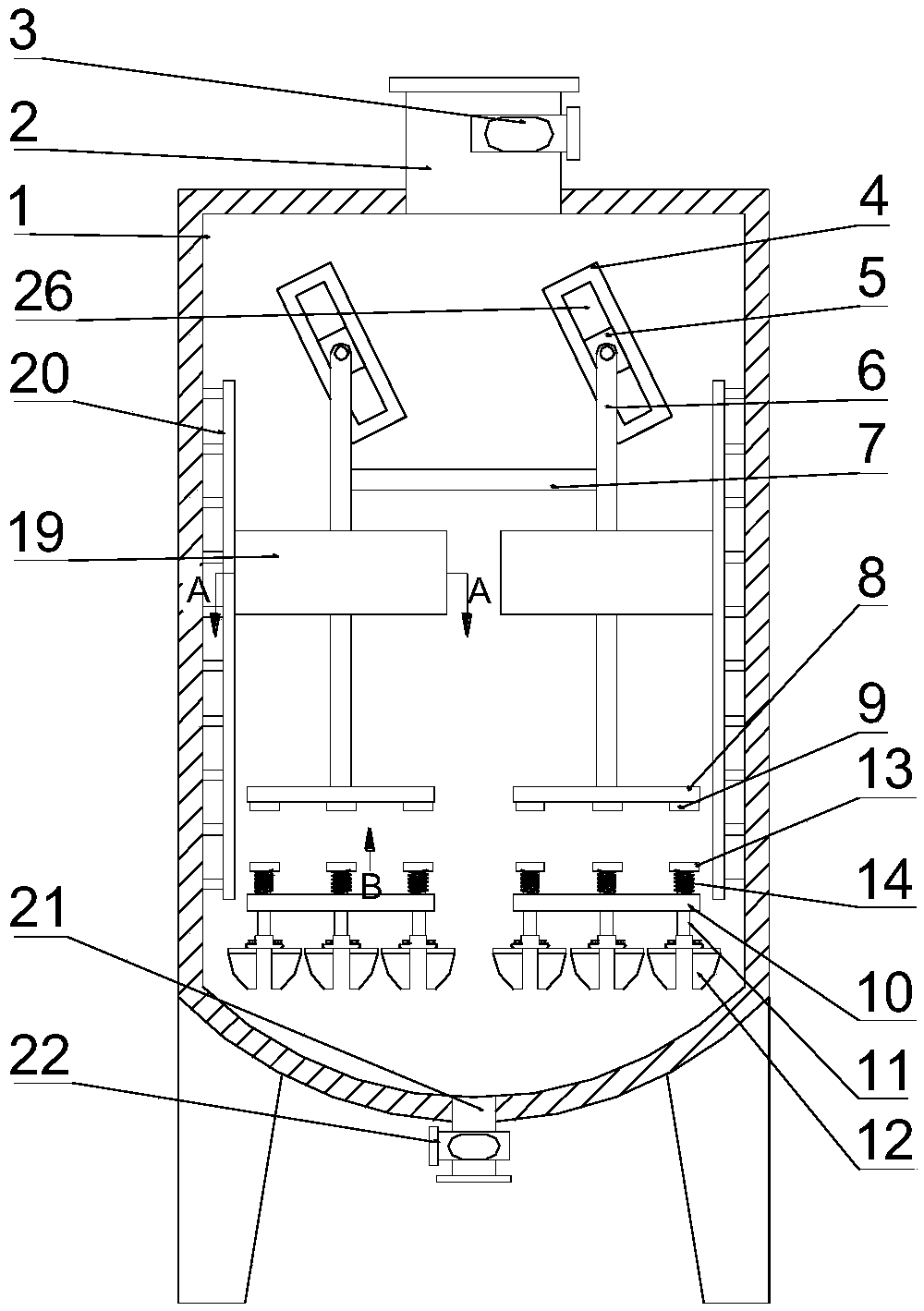

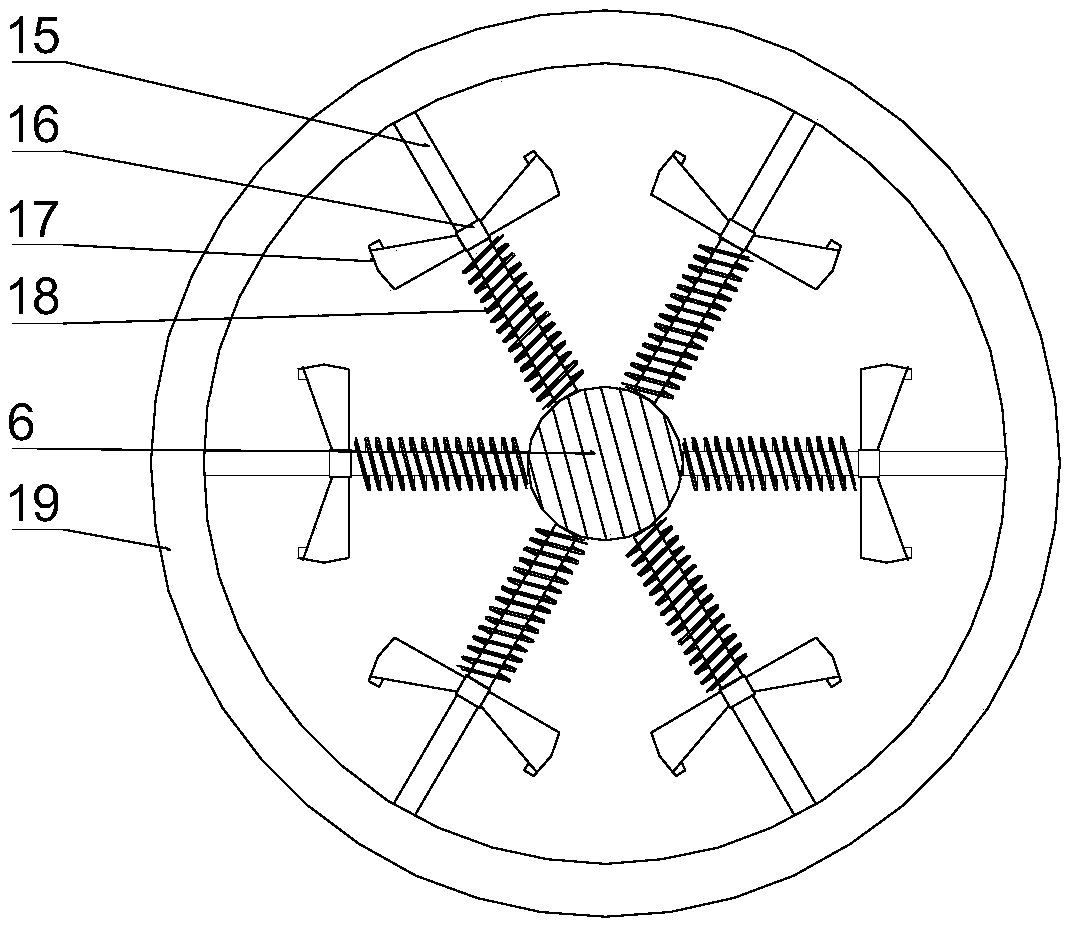

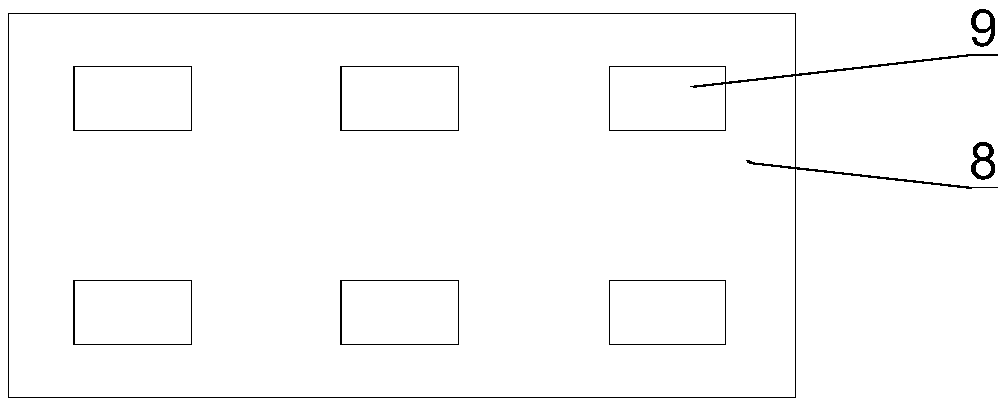

[0024] see Figure 1-4 , a homogenizer for preparing an antifoaming agent for electric power oil, comprising a homogenizing tank 1, a strip block 4 is installed on the inner upper side of the homogenizing tank 1, and a There is a drive mechanism, the output end of the drive mechanism is fixedly connected to the center of the side of the bar block 4, the other side of the bar block 4 is provided with a rectangular groove 26, and the sliding block 5 is slidably connected in the rectangular groove 26. 5 is hinged with a moving rod 6, and the two moving rods 6 on the left and right sides are arranged in parallel and the two moving rods 6 are fixedly connected by a connecting rod 7, and the bottom end of the moving rod 6 is fixedly connected with a moving plate 8, The lower surface of the moving plate 8 is fixedly connected with some magnets 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com