Rotary drum vacuum filtering type water supply industrial waste water treatment device

A technology for rotary drum vacuum filtration and industrial wastewater, which is applied in filtration and separation, moving filter element filters, separation methods, etc. Save manpower and material resources and ensure the effect of filtering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

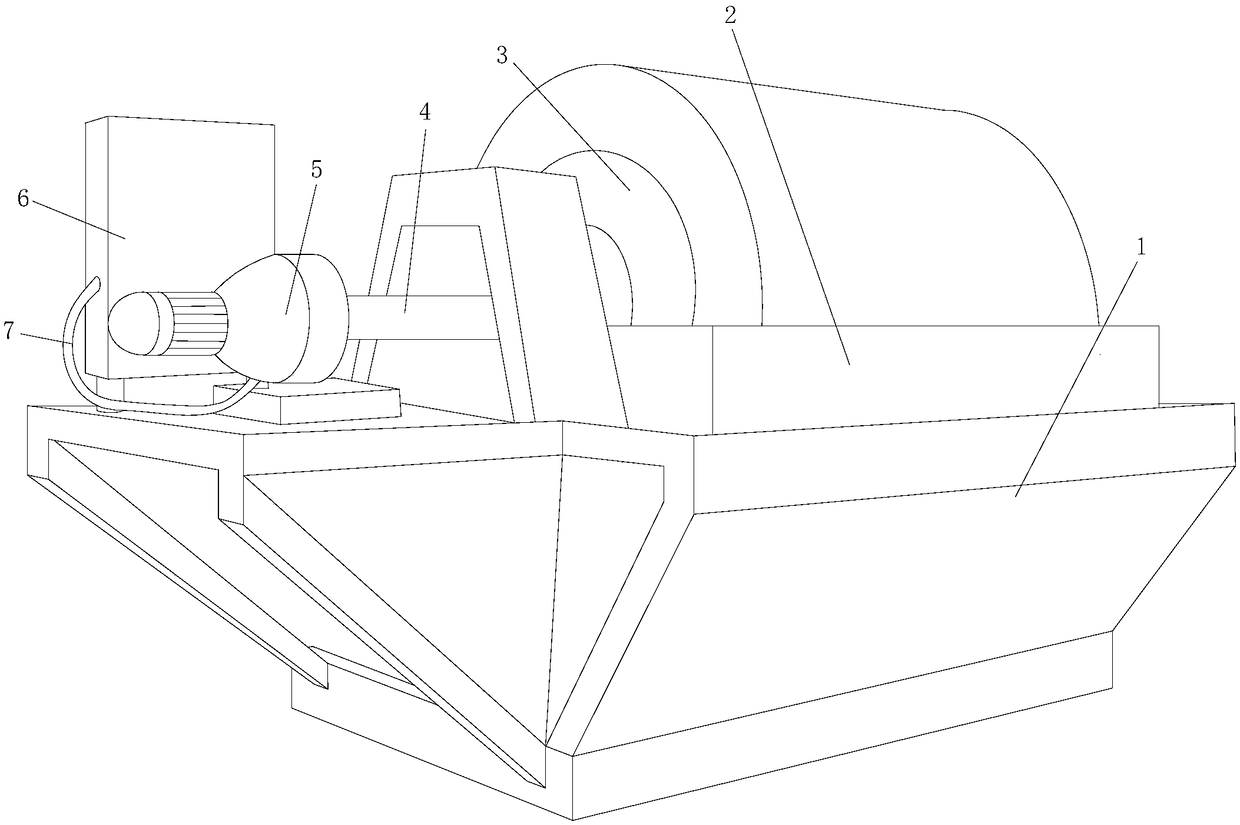

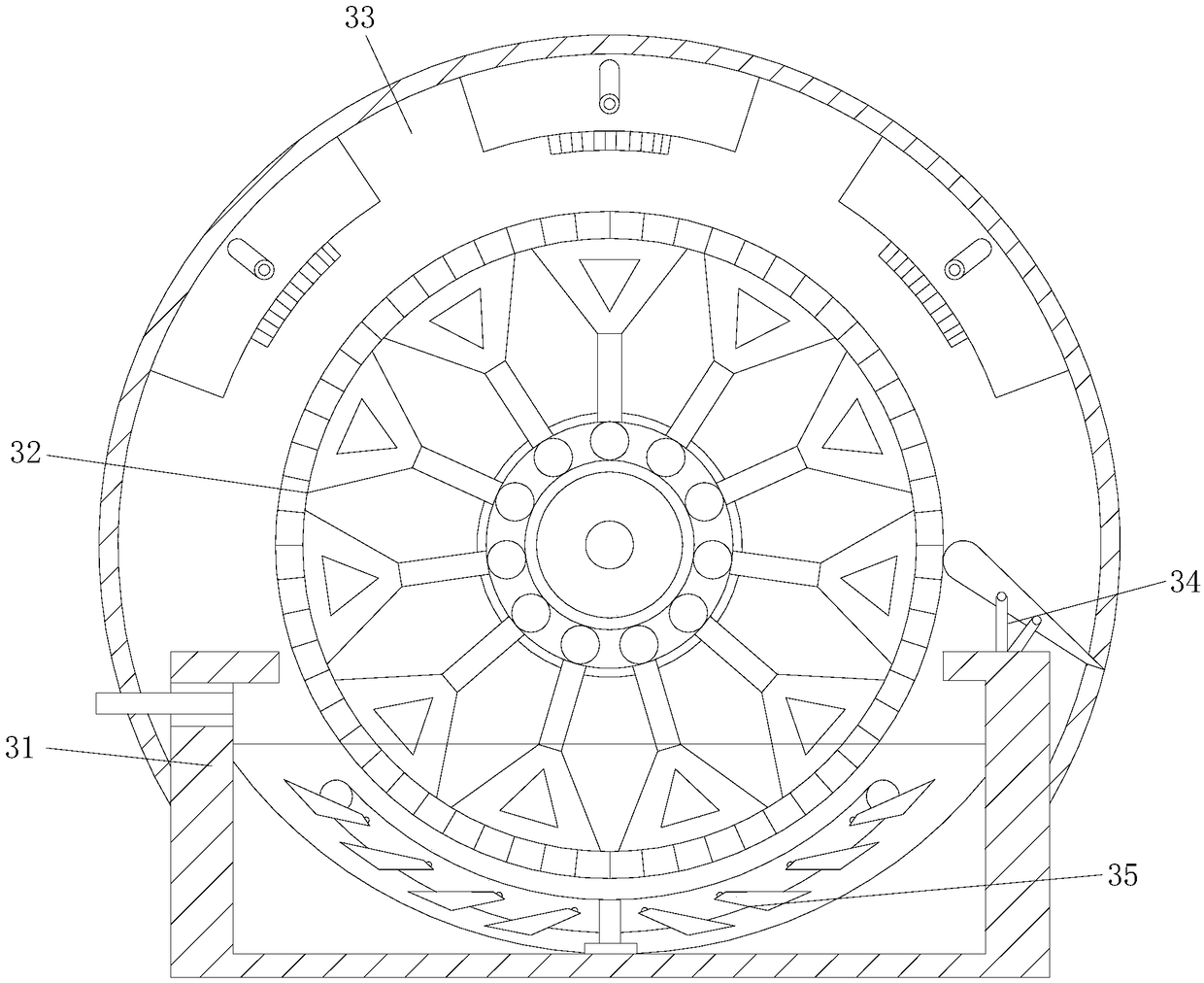

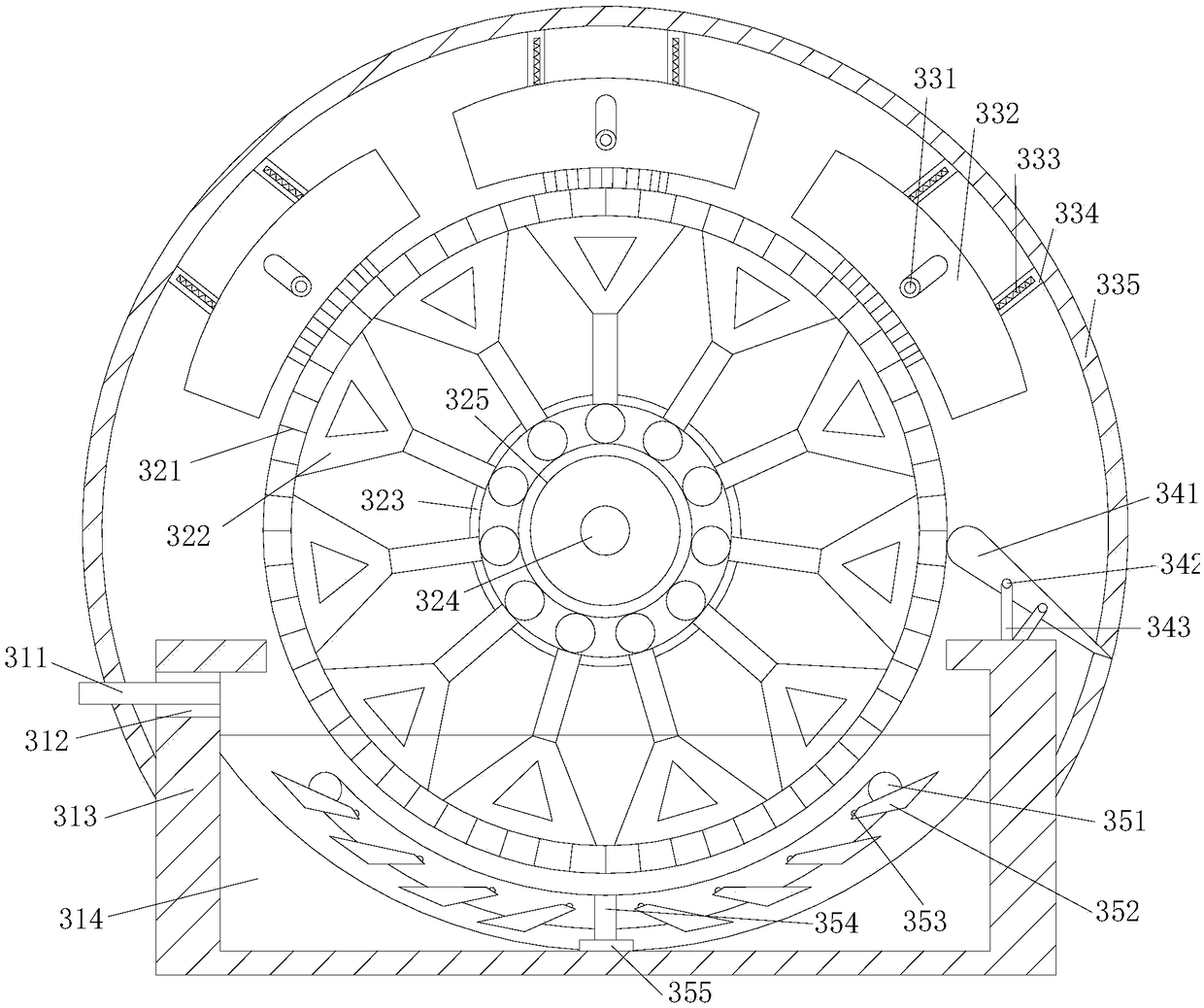

[0026] see Figure 1-Figure 7, the present invention provides a rotary drum vacuum filter type water supply industrial wastewater treatment device, its structure includes a support base 1, a fixed slot plate 2, a vacuum filter scrubbing device 3, a rotating shaft 4, a motor 5, an electric control box 6, and a power cord 7. The bottom end of the fixed slot plate 2 is fixedly connected to the top of the support pedestal 1 by means of electric welding, one end of the rotating shaft 4 is installed inside the vacuum filter scrubbing device 3 by means of embedding, and the other end of the rotating shaft 4 is installed on the motor 5 by means of embedding. Close to the end of the vacuum filter scrubbing device 3, the bottom end of the electric control box 6 is fixedly connected to the support platform 1 by means of electric welding, and the top end is far away from the end of the vacuum filter scrubbing device 3, and the bottom end of the motor 5 is fixedly connected to the support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com