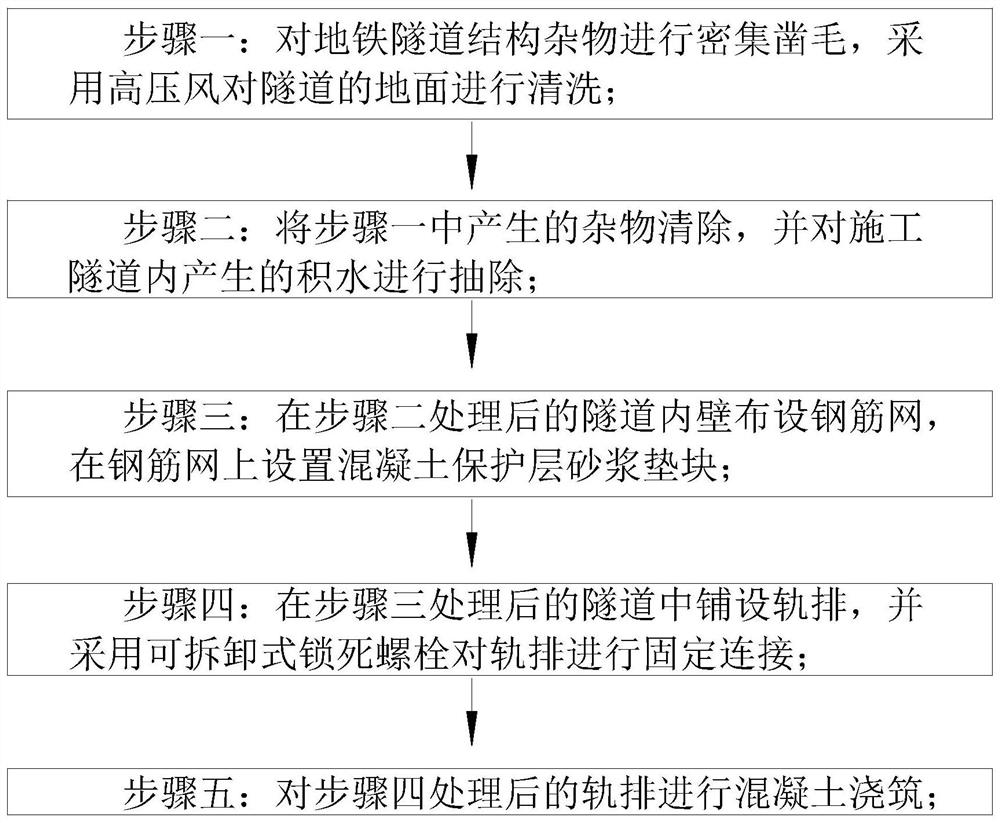

A method for laying subway tracks

A technology for subways and tracks, applied in tracks, track laying, track maintenance, etc., can solve the problems of inconvenient disassembly, limited use of bolts, inconvenient for secondary use of bolts, etc., and achieve the effect of improving pulling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

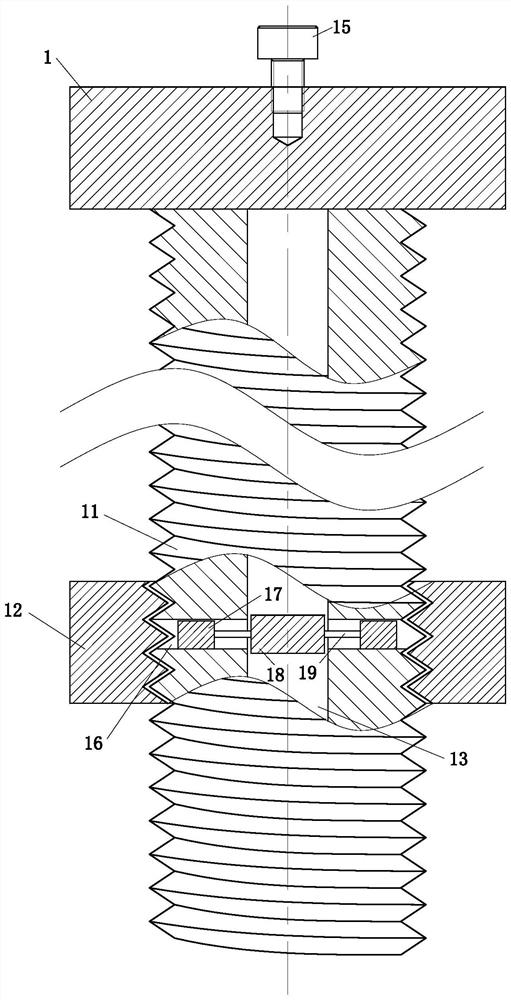

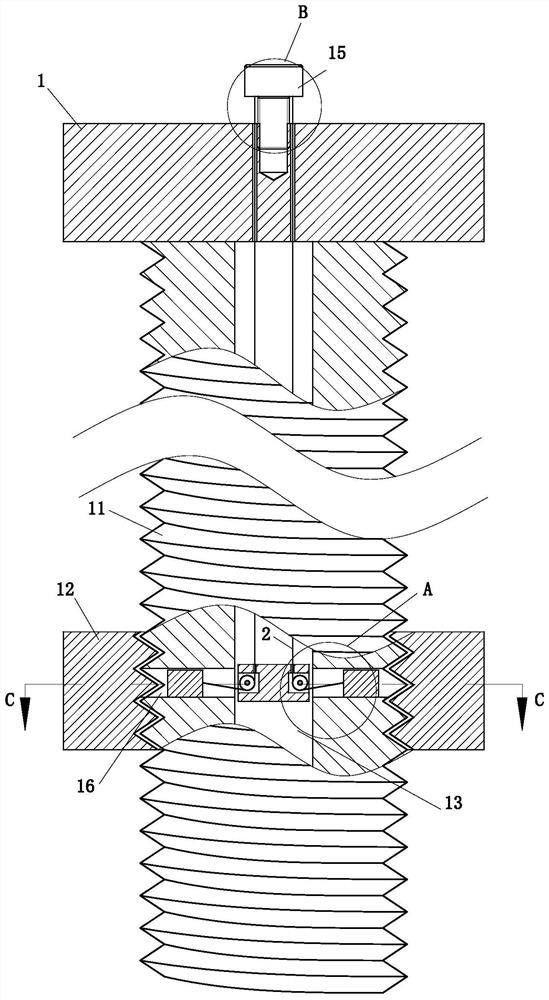

[0051] As an embodiment of the present invention, the locking member 15 is a screw 21, and the upper surface of the first nut 1 is provided with a second threaded hole 22 at the axis position, and the second threaded hole 22 is used for Use with the screw 21; the screw 21 cooperates with the second threaded hole 22 to make the wire rope 2 tighten the friction block 17; when the locking member 15 is the screw 21, the screw 21 can move vertically in the second threaded hole 22 , Thereby driving the wire rope 2 to move in the vertical direction; when the screw 21 is screwed down, the wire rope 2 is in a relaxed state, and the elastic member 19 presses the friction block 17 to fasten the inner wall of the No. 1 nut 12 at this time; The bolt has a loosening function; at the same time, the bolt is not easy to disassemble; when the screw 21 is screwed upwards, the wire rope 2 tightens the friction block 17, so that the friction block 17 does not contact the inner wall of the No. 1 nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com