Polarizing film bending machine

A technology of polarizing film and film machine, applied in the field of polarizing film for lenses, which can solve the problems of polarizing film bending or inaccurate bending, irregular operation of employees, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

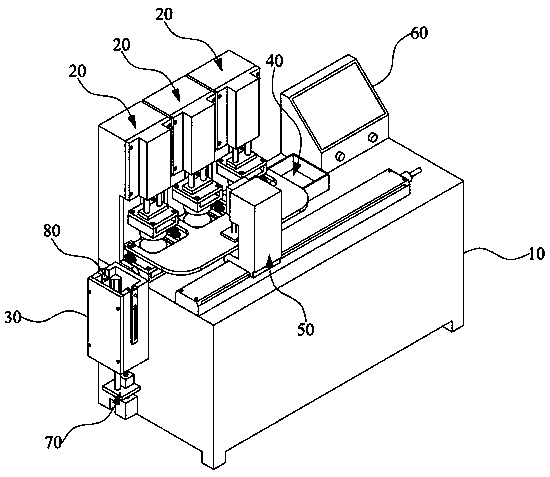

[0029] Please refer to figure 1 , figure 1 It is a perspective view of a polarizing film bending machine according to an embodiment of the present invention. As shown in the figure, a polarizing film bending machine includes a machine platform 10; multiple sets of bending film assemblies 20 arranged on the machine platform 10; 30, the feeding bin 30 stacks polarizing films; the receiving frame 40 arranged on the machine 10 and on the other side of the multiple groups of curved film components 20; the suction component 50 installed on the machine 10, the suction component 50 absorbs polarized light The film bends to multiple sets of bending film assemblies 20 and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com