Gear appearance detection channel and working method thereof

A detection channel and appearance inspection technology, applied in sorting and other directions, can solve the problems of inability to guarantee the sorting quality, complex gear tooth structure, low work efficiency, etc., to achieve appearance inspection, expand tooth surface range, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

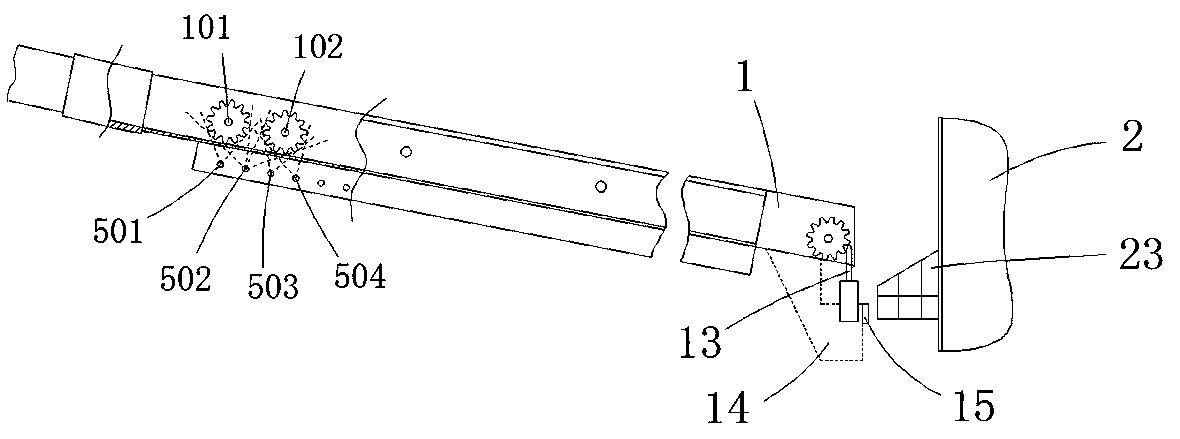

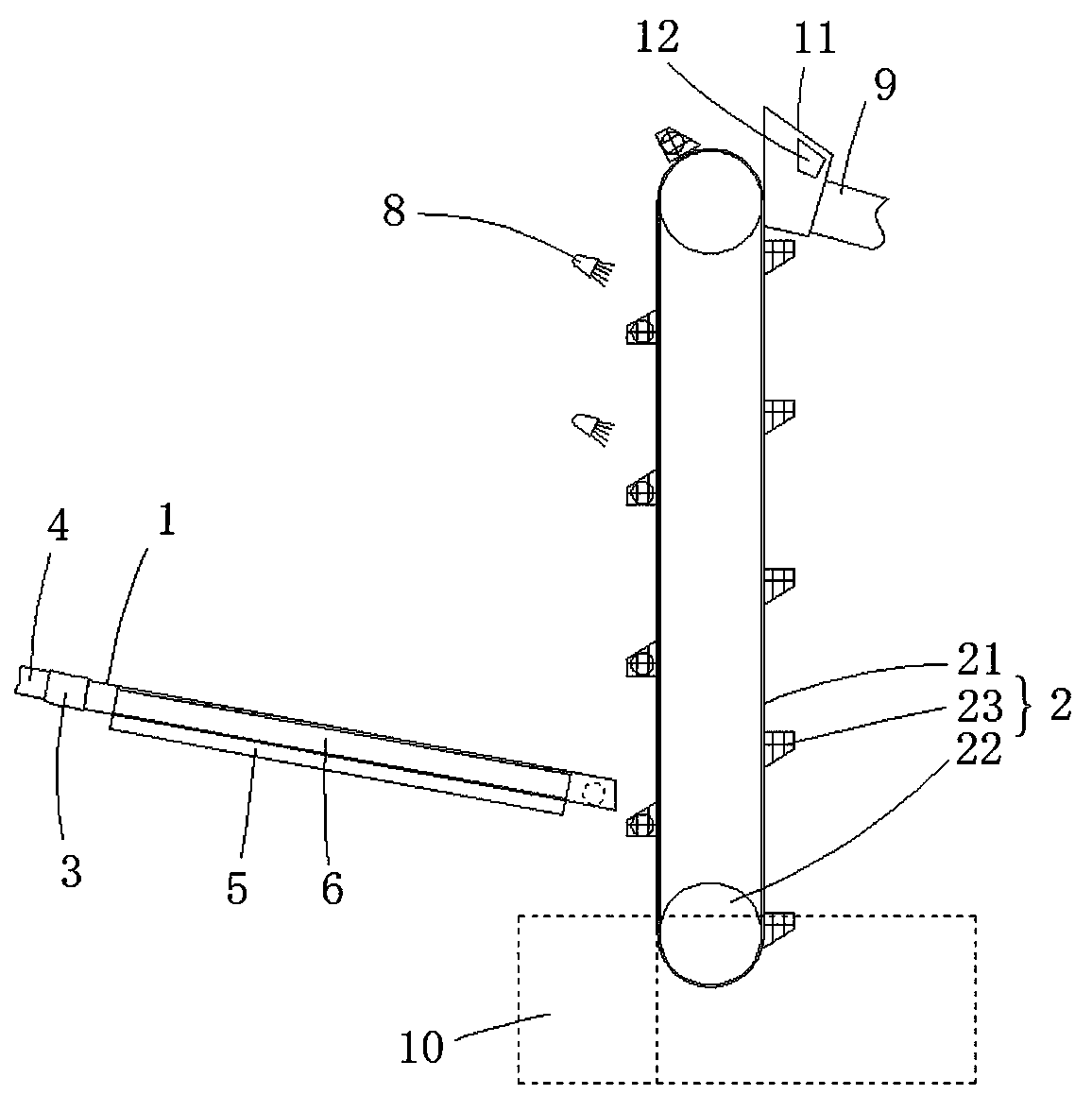

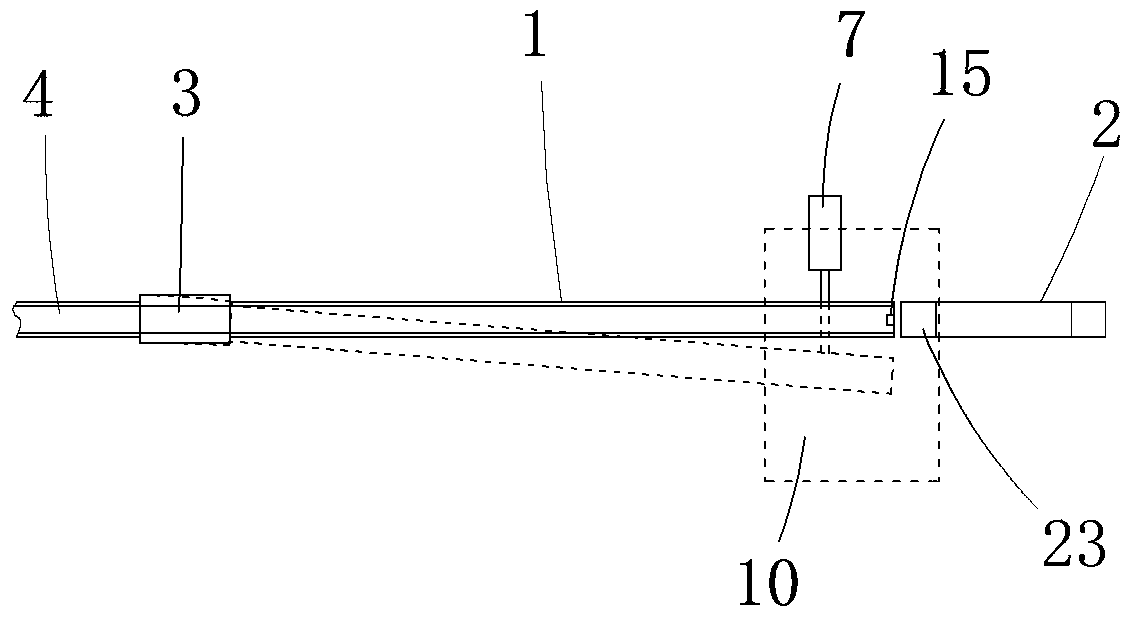

[0026] A gear appearance detection channel of the present invention, such as Figure 1 to Figure 3 As shown, it includes an inclined detection channel 1 and a vertically arranged conveyor chain structure 2, the detection channel 1 is facing the conveyor chain structure 2; the conveyor chain structure 2 is provided with a group of loading frames 23, and the one The group loading frame 23 moves circularly under the drive of the conveyor chain structure 2; the detection channel 1 is connected to the feed port 4 through the flexible part 3, and the detection channel 1 is provided with a transposition drive device 7, and the transposition drive device 7 is set at the end of the detection channel 1 close to the conveyor chain structure 2, the end of the detection channel 1 can deviate from the conveyor chain structure 2 driven by the transposition drive device 7; the bottom of the detection channel 1 is provided with a tooth surface detection device 5 , the two side walls are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com