Method for carrying out rubber coating and fixing on lithium ion battery cell

A lithium-ion battery and lithium-ion technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as low efficiency, wrinkled diaphragm, poor adhesive tape, etc., to optimize the existing fixing technology and improve Better production efficiency and pasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Preferably, the preparation method of described glue solution specifically comprises the following steps:

[0050] (1) Add the binder into the solvent and stir to make it fully dissolve;

[0051] (2) Continue stirring after dissolving, then reduce the stirring speed, and stir until the viscosity of the glue is 1000-5000mpas to obtain the glue.

[0052] Preferably, in step (1), the stirring time is 0.5-1.5h, more preferably 1-1.5h.

[0053] Preferably, in step (2), the time for continuing stirring is 2-3.5 h, more preferably 2-3 h.

[0054] The glue is prepared by a characteristic method, the binder is added to the solvent and stirred to make it fully dissolved, the binder is added to the solvent and stirred, fully dissolved, continued to stir after dissolving, and then slow down the stirring speed to eliminate air bubbles. Test the viscosity of the obtained slurry. If the viscosity is 1000-5000mpas, it can be discharged. If the viscosity is higher than 5000mpas, add s...

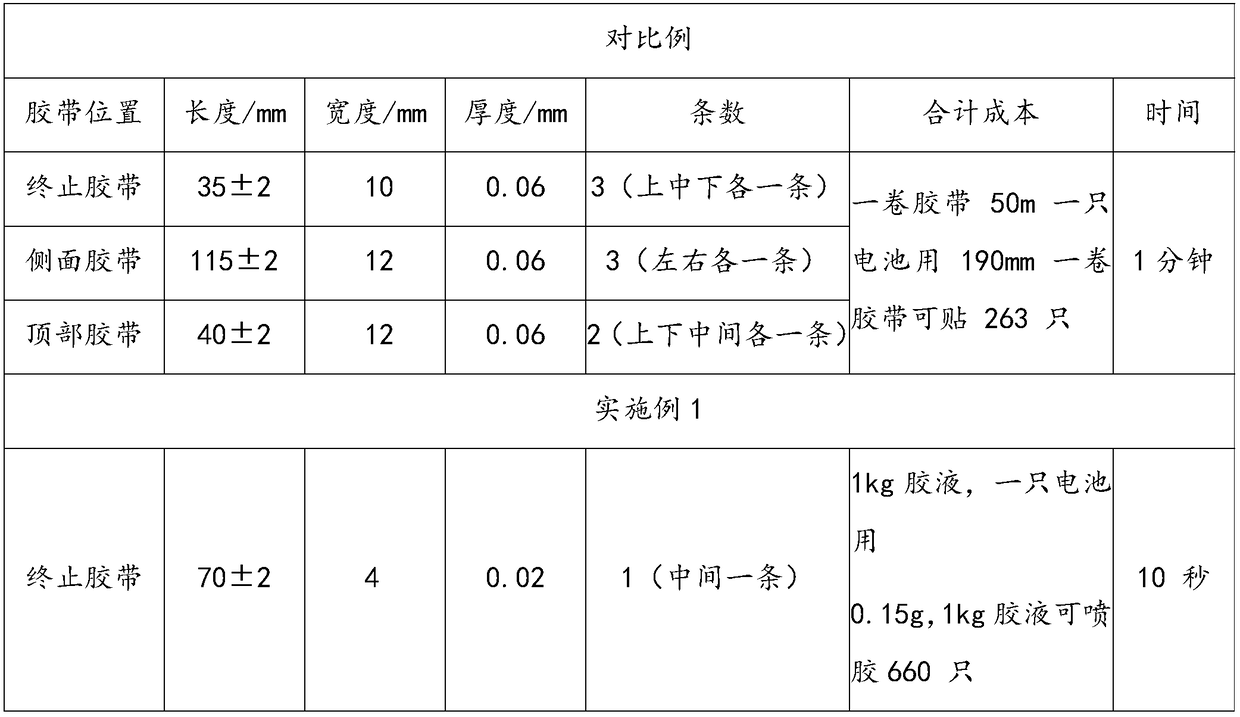

Embodiment 1

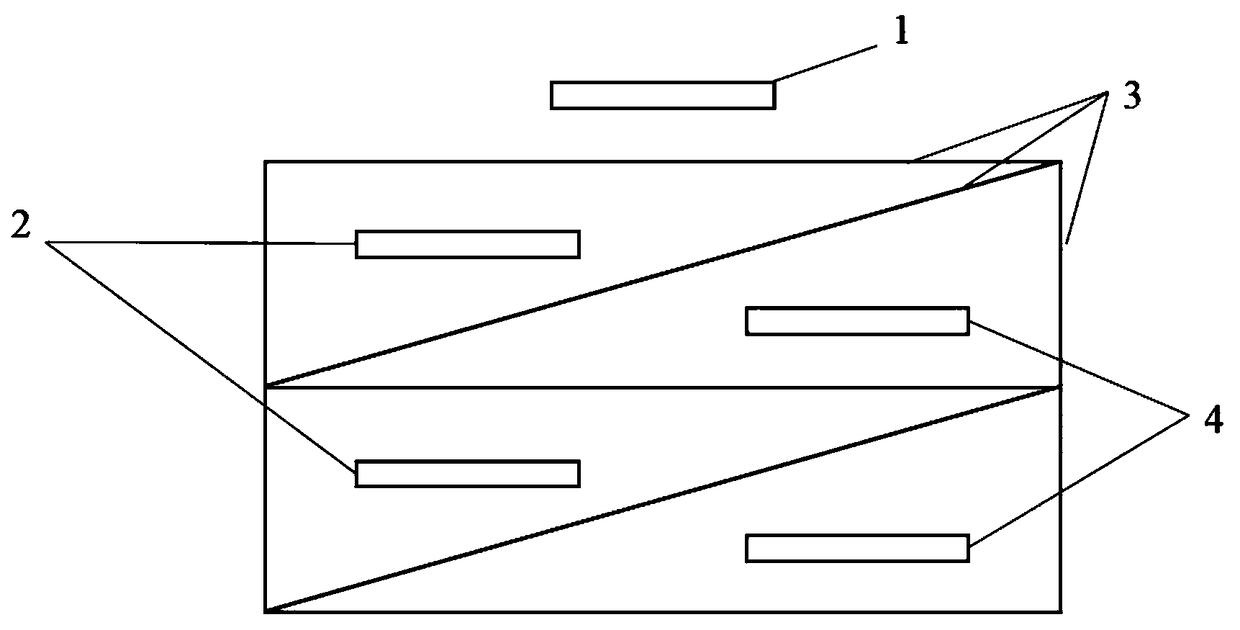

[0056] The diaphragm is wrapped around the positive electrode sheet or negative electrode sheet stacked with lithium ions, and the end of the diaphragm wrapped is pasted and fixed on the middle part of the positive electrode sheet or negative electrode sheet with glue; specifically, the prepared glue is sprayed through a special nozzle At the end of the diaphragm, the glue solution was dried and fixed at 65°C.

[0057] Wherein, glue adopts following method to prepare:

[0058] (1) Add 3 parts of polyvinylidene fluoride binder with a molecular weight of 10,000 to 97 parts of acetone and stir for 0.5 hours, continue stirring for 2 hours after fully dissolving, and then slow down the stirring speed to eliminate air bubbles;

[0059] (2) Viscosity test is carried out on the obtained slurry, if the viscosity is 1000-5000mpas, then it can be discharged; if the viscosity is higher than 5000mpas, then add some solvent and stir until the viscosity meets the requirements.

Embodiment 2

[0061] The diaphragm is wrapped around the positive electrode sheet or negative electrode sheet stacked with lithium ions, and the end of the diaphragm wrapped is pasted and fixed on the middle part of the positive electrode sheet or negative electrode sheet with glue; specifically, the prepared glue is sprayed through a special nozzle At the end of the diaphragm, the glue was dried and fixed at 75°C.

[0062] Wherein, glue adopts following method to prepare:

[0063] (1) Add 12 parts of polyvinylidene fluoride binder with a molecular weight of 1,500,000 to 88 parts of acetone and stir for 1.5 hours, continue stirring for 2.5 hours after fully dissolving, and then slow down the stirring speed to eliminate air bubbles;

[0064] (2) Viscosity test is carried out to the obtained slurry, if the viscosity is 3000-5000mpas, then it can be discharged; if the viscosity is higher than 5000mpas, then add some solvent and stir until the viscosity meets the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com