Coal rock brittleness evaluation method

An evaluation method, coal and rock technology, applied in the direction of strength characteristics, instruments, measuring devices, etc., can solve problems such as inapplicability of coal rock brittleness, deviation of evaluation results, and failure to consider the influence of the weak surface of the cleat system structure, etc., to achieve good pressure Cracking effect, strong practicability, real and reliable results of brittleness evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention will be further described:

[0041] The brittleness evaluation method of coal rock is as follows:

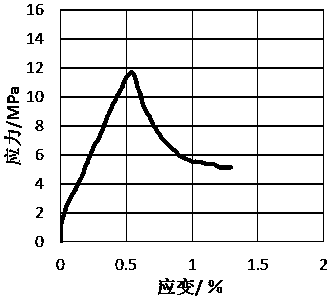

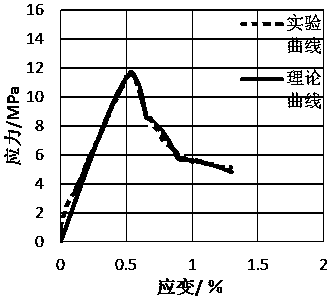

[0042] Step 1. Carry out on-site coring of coal and rock in the target fracturing well layer, prepare standard rock samples for uniaxial compression mechanical parameter testing, φ25*50mm or φ50*100mm core, carry out uniaxial compression experiments, and test to obtain the full stress-strain curve (Such as figure 1 shown) and corresponding experimental data;

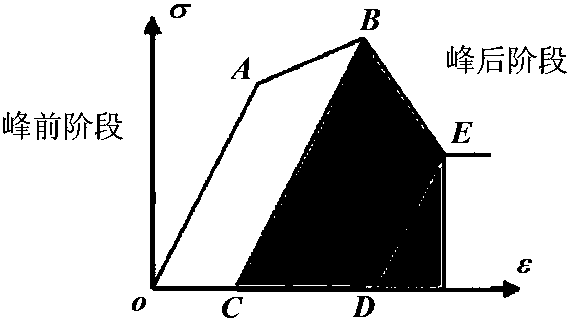

[0043] Step 2. Using statistical damage theory to describe the development of internal cleats and cracks in coal rocks, and establishing a rock damage constitutive model with power function distribution:

[0044]

[0045] In the formula: σ is the applied axial stress, MPa; E is the elastic modulus of the core, MPa; ε is the strain of the core; m, ε 0 is a power function distribution parameter, which can be obtained by fitting the rock stress-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com